Hello SimpleFOC community,

I am working on a project to control a hoverboard motor using an ESP32 and the TMC6200-BOB module with the SimpleFOC library. I am also using the built-in Hall effect sensor in the motor for feedback control. However, I am experiencing some strange behavior with the motor control and I am seeking help from the community.

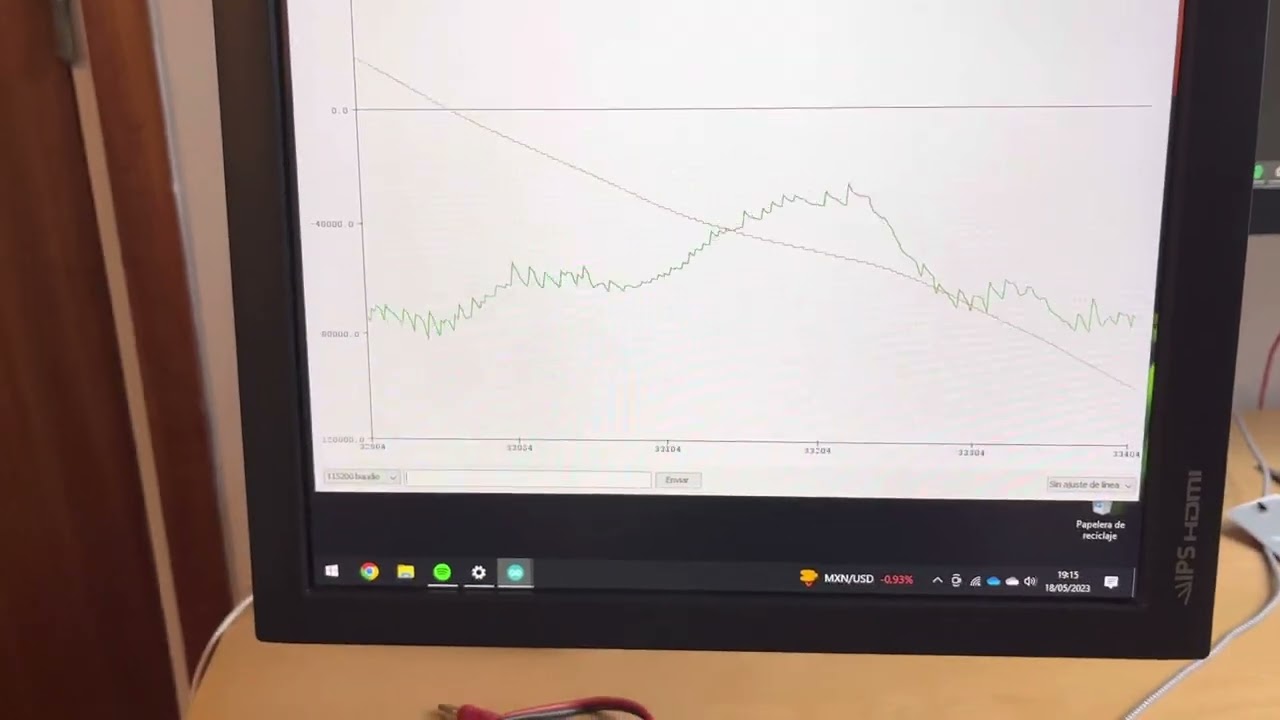

I have been using the SimpleFOC library example codes for motion control and speed control, and both seem to be working well. However, at certain points, the motor seems to get stuck, drawing a large amount of current and stopping completely. I have to manually dislodge the motor, after which it continues to work until it gets stuck again.

I have checked the wiring and connections multiple times but the issue persists. I am hoping that someone in the community has experienced a similar issue or has any suggestions on how to troubleshoot the problem.

The code that I’m actualy using is this one (the hall efect sensor speed control) :

#include <Arduino.h>

#include <SimpleFOC.h>

// BLDC motor & driver instance

// BLDCMotor motor = BLDCMotor(pole pair number);

BLDCMotor motor = BLDCMotor(15);

// BLDCDriver3PWM driver = BLDCDriver3PWM(pwmA, pwmB, pwmC, Enable(optional));

BLDCDriver6PWM driver = BLDCDriver6PWM(23, 22, 33, 25, 26, 27);

// Stepper motor & driver instance

//StepperMotor motor = StepperMotor(50);

//StepperDriver4PWM driver = StepperDriver4PWM(9, 5, 10, 6, 8);

// hall sensor instance

HallSensor sensor = HallSensor(18, 19, 21, 15);

// Interrupt routine intialisation

// channel A and B callbacks

void doA(){sensor.handleA();}

void doB(){sensor.handleB();}

void doC(){sensor.handleC();}

// If no available hadware interrupt pins use the software interrupt

// velocity set point variable

float target_velocity = 0;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&target_velocity, cmd); }

void setup() {

// initialize sensor sensor hardware

sensor.init();

sensor.enableInterrupts(doA, doB, doC);

// link the motor to the sensor

motor.linkSensor(&sensor);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// aligning voltage [V]

motor.voltage_sensor_align = 3;

// set motion control loop to be used

motor.controller = MotionControlType::velocity;

// contoller configuration

// default parameters in defaults.h

// velocity PI controller parameters

motor.PID_velocity.P = 0.2f;

motor.PID_velocity.I = 2;

motor.PID_velocity.D = 0;

// default voltage_power_supply

motor.voltage_limit = 3;

// jerk control using voltage voltage ramp

// default value is 300 volts per sec ~ 0.3V per millisecond

motor.PID_velocity.output_ramp = 1000;

// velocity low pass filtering time constant

motor.LPF_velocity.Tf = 0.01f;

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add target command T

command.add('T', doTarget, "target voltage");

Serial.println(F("Motor ready."));

Serial.println(F("Set the target velocity using serial terminal:"));

_delay(1000);

}

void loop() {

// main FOC algorithm function

// the faster you run this function the better

// Arduino UNO loop ~1kHz

// Bluepill loop ~10kHz

motor.loopFOC();

// Motion control function

// velocity, position or voltage (defined in motor.controller)

// this function can be run at much lower frequency than loopFOC() function

// You can also use motor.move() and set the motor.target in the code

motor.move(target_velocity);

// function intended to be used with serial plotter to monitor motor variables

// significantly slowing the execution down!!!!

// motor.monitor();

// user communication

command.run();

}

Here I’ve posted a video were you can see what I’m talking about: https://youtu.be/FwxsQjwYyXU

If anyone has any advice or suggestions, please let me know. Thank you in advance for your help.

Thanks in advance,

Marc