Hello,

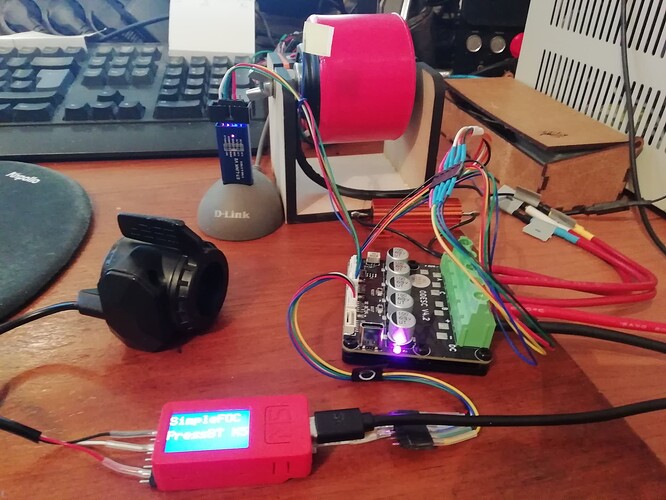

I bought an ODESC 4.2 card (24volt) with STM32F405RGT6, a Chinese card that runs under Odrive3.6.

https://fr.aliexpress.com/item/1005005725467528.html

I got it to work with SimpleFOC ![]()

It works perfectly if I drive it with STMViewer and a “St-Link V2”.

The motor is a skateboard motor in 24v 150w and 10 poles with Hall effect sensor.

I can’t get a continuous potentiometer reading to work properly.

I first tried adding analogRead() from GPIO ==> PA0 to the loop,

It doesn’t work, it disturbs the motor operation,

analogRead() slows down the loop too much…

So I thought I’d add a connection with “SoftwareSerial.h” and “Commander command = Commander(mySerial)”.

and “Commander command = Commander(mySerial);”

Likewise, each time a potentiometer parameter is sent, makes the engine jerk…

How do you continuously read a potentiometer?

sorry, my English is very bad ![]()

My code test build_opt.h:

-D HAL_OPAMP_MODULE_ENABLED

-D PIO_FRAMEWORK_ARDUINO_ENABLE_CDC

-D PIO_FRAMEWORK_ARDUINO_NANOLIB_FLOAT_PRINTF

-D PIO_FRAMEWORK_ARDUINO_USB_HIGHSPEED_FULLMODE

-D SIMPLEFOC_DISABLE_DEBUG

-g -ggdb

Arduino:

/*

SimpleFOC_STM32F405RGT6

odrive 3.6 - odesk 4.2

Hall sensor example code

This is a code intended to test the hall sensors connections and to demonstrate the hall sensor setup.

odrive_example_encoder.ino

https://github.com/simplefoc/Arduino-FOC/blob/dev/examples/hardware_specific_examples/Odrive_examples/odrive_example_encoder/odrive_example_encoder.ino

https://community.simplefoc.com/t/problems-with-custom-firmware-for-odrive-v3-5-using-simplefoc/2743

#include <Arduino.h>

#include <Wire.h>

https://github.com/simplefoc/Arduino-FOC/tree/master/examples/hardware_specific_examples/Odrive_examples

*/

#include <SimpleFOC.h>

//M0

#define A_HALL1 PB4

#define A_HALL2 PB5

#define A_HALL3 PC9

//M0

//#define M0_IA // _NC ????????????

#define M0_IB PC0

#define M0_IC PC1

// Odrive M0 motor pinout

#define M0_INH_A PA8

#define M0_INH_B PA9

#define M0_INH_C PA10

#define M0_INL_A PB13

#define M0_INL_B PB14

#define M0_INL_C PB15

// M1 & M2 common enable pin

#define EN_GATE PB12

//Pole pair

#define PP 10

//Temp

#define M0_TEMP PC5

// Motor instance

BLDCMotor motor = BLDCMotor(PP);

//BLDCDriver6PWM driver = BLDCDriver6PWM(PC6, PA7, PC7, PB0, PC8, PB1, PB12);

BLDCDriver6PWM driver = BLDCDriver6PWM(M0_INH_A, M0_INL_A, M0_INH_B, M0_INL_B, M0_INH_C, M0_INL_C, EN_GATE);

// low side current sensing define

// 0.0005 Ohm resistor

// gain of 10x

// current sensing on B and C phases, phase A not connected

LowsideCurrentSense currentSense = LowsideCurrentSense(0.0005f, 10.0f, _NC, M0_IB, M0_IC);

// Hall sensor instance

// HallSensor(int hallA, int hallB , int cpr, int index)

// - hallA, hallB, hallC - HallSensor A, B and C pins

// - pp - pole pairs

HallSensor sensor = HallSensor(A_HALL1, A_HALL2, A_HALL3, PP); // PP = xx aimants / 2 = pole pair

// Interrupt routine intialisation

// channel A and B callbacks

void doA() {

sensor.handleA();

}

void doB() {

sensor.handleB();

}

void doC() {

sensor.handleC();

}

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬SoftwareSerial▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

#include <SoftwareSerial.h>

// SPI pinout mosi/miso ==> Utilisé pour serial RX/TX

#define SERIAL_RX PA3 //PC12

#define SERIAL_TX PA2 //PC11

// Set up a new SoftwareSerial object

SoftwareSerial mySerial = SoftwareSerial(SERIAL_RX, SERIAL_TX);

// https://docs.simplefoc.com/communication

// instantiate the commander

Commander command = Commander(mySerial);

// motor SimpleFOCStudio ==> M

void doMotor(char* cmd) {

//command.motor(&motor, cmd);

command.target(&motor, cmd);

//command.motion(&motor,cmd);

}

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬setup▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

void setup() {

//▬▬▬▬▬▬▬▬▬▬▬▬GPIO1/GPIO2/GPIO3/GPIO4▬▬▬▬▬▬▬▬▬▬▬▬

/*

pinMode(PA0, OUTPUT); // GPIO1

digitalWrite(PA0, LOW); // HIGH/LOW

pinMode(PA1, OUTPUT); // GPIO2

digitalWrite(PA1, LOW); // HIGH/LOW

pinMode(PA2, OUTPUT); // GPIO3

digitalWrite(PA2, LOW); // HIGH/LOW

pinMode(PA3, OUTPUT); // GPIO4

digitalWrite(PA3, LOW); // HIGH/LOW

*/

//▬▬▬▬▬▬▬▬▬▬▬▬Temp▬▬▬▬▬▬▬▬▬▬▬▬

pinMode(M0_TEMP, INPUT); // M0_TEMP PC5

//▬▬▬▬▬▬▬▬▬▬▬▬SoftwareSerial▬▬▬▬▬▬▬▬▬▬▬▬

// Define pin modes for TX and RX

pinMode(SERIAL_RX, INPUT_PULLUP); // sur GPIO PA3

pinMode(SERIAL_TX, OUTPUT); // sur GPIO PA2

mySerial.begin(115200); // 115200 Set the baud rate for the SoftwareSerial object

_delay(1000);

//▬▬▬▬▬▬▬▬▬▬▬▬driver▬▬▬▬▬▬▬▬▬▬▬▬

// pwm frequency to be used [Hz]

driver.pwm_frequency = 20000; // 20000 max SRM32

driver.voltage_power_supply = 24.0f; // power supply voltage [V]

driver.voltage_limit = 24.0f; // Max DC voltage allowed - default voltage_power_supply

driver.init();// driver init

motor.linkDriver(&driver); // link the motor and the driver

//▬▬▬▬▬▬▬▬▬▬▬▬Current▬▬▬▬▬▬▬▬▬▬▬▬

// ici passe pas ?

//▬▬▬▬▬▬▬▬▬▬▬▬sensor▬▬▬▬▬▬▬▬▬▬▬▬

sensor.pullup = Pullup::USE_EXTERN; // check if you need internal pullups

sensor.init(); // initialise encoder hardware

sensor.enableInterrupts(doA, doB, doC); // hardware interrupt enable

motor.linkSensor(&sensor);

_delay(1000);

//▬▬▬▬▬▬▬▬▬▬▬▬mode▬▬▬▬▬▬▬▬▬▬▬▬

// set torque mode

// https://docs.simplefoc.com/foc_current_torque_mode

motor.torque_controller = TorqueControlType::foc_current; // foc_current || dc_current || voltage

motor.controller = MotionControlType::velocity; // angle velocity torque // Control loop type

// choose FOC modulation

// FOCModulationType::SinePWM; (default)

// FOCModulationType::SpaceVectorPWM;

// FOCModulationType::Trapezoid_120;

// FOCModulationType::Trapezoid_150;

motor.foc_modulation = FOCModulationType::SinePWM; // pwm modulation settings

motor.modulation_centered = 1; // 1

//▬▬▬▬▬▬▬▬▬▬▬▬ALL_PID▬▬▬▬▬▬▬▬▬▬▬▬

// velocity PID

motor.PID_velocity.P = 0.1f; // 0.2

motor.PID_velocity.I = 1.0f; // 2.0

motor.PID_velocity.D = 0.001; // 0.001

//motor.PID_velocity.output_ramp = 1000.0;

//motor.PID_velocity.limit = 1.0; // ? current_limit [Amps] // https://community.simplefoc.com/t/setting-current-limits-in-main-loop/1972

motor.LPF_velocity.Tf = 0.01; //0.01 // Low pass filtering time constant

// angle PID

motor.P_angle.P = 30.0; // 14.0

motor.P_angle.I = 0.0;

motor.P_angle.D = 0.0;

motor.P_angle.output_ramp = 10000.0; // 10000.0

//motor.P_angle.limit = 50.0; // ? velocity_limit [rad/s]

motor.LPF_angle.Tf = 0.001; // Low pass filtering time constant

// current q PID

motor.PID_current_q.P = 1.0; // 3

motor.PID_current_q.I = 100.0; // 300

//motor.PID_current_q.D = 0.0;

//motor.PID_current_q.output_ramp = 1000.0f;

//motor.PID_current_q.limit = 3.0; // https://community.simplefoc.com/t/setting-current-limits-in-main-loop/1972

//motor.LPF_current_q.Tf = 0.005; // Low pass filtering time constant

// current d PID

motor.PID_current_d.P = 1.0; // 3

motor.PID_current_d.I = 100.0; // 300

//motor.PID_current_d.D = 0.0;

//motor.PID_current_d.output_ramp = 1000.0f;

//motor.PID_current_d.limit = 3.0; // https://community.simplefoc.com/t/setting-current-limits-in-main-loop/1972

//motor.LPF_current_d.Tf = 0.005; // Low pass filtering time constant

//▬▬▬▬▬▬▬▬▬▬▬▬Limits▬▬▬▬▬▬▬▬▬▬▬▬

motor.velocity_limit = 3.0f; // [rad/s] (120[rad/s] ==> ~1200[RPM])

motor.voltage_limit = 0.5 * driver.voltage_limit; // [Volts] // Calcul ==> 5.57[Ohms]*1.0[Amps]=5,57[Volts] // [V] - if phase resistance not defined

//motor.voltage_limit = 24.0f; // [Volts] // Calcul ==> 5.57[Ohms]*1.0[Amps]=5,57[Volts] // [V] - if phase resistance not defined

motor.current_limit = 5.0f; // Current limit [Amps] - if phase resistance defined

motor.phase_resistance = 0.5f; // [Ohms] // motor phase resistance // I_max = V_dc/R

motor.KV_rating = 100; // [rpm/Volt] - default not set // motor KV rating [rpm/V]

// commenter les 2 ci-dessous pour avoir le test au demarrage

motor.zero_electric_angle = 2.09f; // 4.19 // zero_electric_angle

motor.sensor_direction = Direction::CCW; // Cw/CCW // direction

//▬▬▬▬▬▬▬▬▬▬▬▬SimpleFOCDebug▬▬▬▬▬▬▬▬▬▬▬▬

// https://docs.simplefoc.com/debugging

//SimpleFOCDebug::enable(NULL);

//SimpleFOCDebug::enable(&mySerial);

//▬▬▬▬▬▬▬▬▬▬▬▬motion_downsample▬▬▬▬▬▬▬▬▬▬▬▬

/*

Pour de nombreuses applications de contrôle de mouvement, il est judicieux d'exécuter

plusieurs boucles de contrôle de couple pour chaque boucle de contrôle de mouvement.

Cela peut avoir un impact important sur la fluidité et peut fournir de meilleures performances à grande vitesse.

C'est pourquoi cette bibliothèque permet une stratégie de sous-échantillonnage très simple pour la fonction move()

qui est définie à l'aide du paramètre

La stratégie de downsampling fonctionne de manière très simple, même si la fonction motor.move()

est appelée dans chaque boucle arduino, elle ne sera exécutée qu'à chaque fois que motor.motion_downsample sera appelé.

Ce paramètre est optionnel et peut être configuré en temps réel.

*/

motor.motion_downsample = 0; // 0 https://docs.simplefoc.com/bldcmotor

//▬▬▬▬▬▬▬▬▬▬▬▬init▬▬▬▬▬▬▬▬▬▬▬▬

motor.init(); // initialise motor

//▬▬▬▬▬▬▬▬▬▬▬▬linkCurrentSense▬▬▬▬▬▬▬▬▬▬▬▬

// https://docs.simplefoc.com/inline_current_sense

currentSense.linkDriver(&driver); // link the driver

currentSense.init(); // init the current sense

currentSense.skip_align = true;

motor.linkCurrentSense(¤tSense);

//▬▬▬▬▬▬▬▬▬▬▬▬initFOC▬▬▬▬▬▬▬▬▬▬▬▬

motor.initFOC(); // init FOC

//▬▬▬▬▬▬▬▬▬▬▬▬command▬▬▬▬▬▬▬▬▬▬▬▬

// https://docs.simplefoc.com/commander_interface

// add the motor to the commander interface

command.decimal_places = 4; // default 3

command.add('M', doMotor, "motor exemple ==> M10"); // The letter (here 'M') you will provide to the SimpleFOCStudio

//▬▬▬▬▬▬▬▬▬▬▬▬target▬▬▬▬▬▬▬▬▬▬▬▬

motor.target = 0;

_delay(1000);

} // End setup

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬End_setup▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬loop▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// current https://docs.simplefoc.com/inline_current_sense

PhaseCurrent_s current;// getPhaseCurrents

float actual_rpm;

long loop_count = 0;// loop down-sampling counter

void loop() {

current = currentSense.getPhaseCurrents();

float current_magnitude = currentSense.getDCCurrent(); // https://docs.simplefoc.com/inline_current_sense#example-code

/*

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬mySerial_send▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// On envoie au M5StickC-plus la vitesse en RPM

if (loop_count++ > 1000) { // control loop each ~xx ms

//actual_rpm = (sensor.getVelocity() * 9.5492968) * -1;

actual_rpm = sensor.getVelocity();

//mySerial.println(actual_rpm);

String toSEND = (String(actual_rpm) + "\n");

//mySerial.write((char*)toSEND.c_str());

loop_count = 0; // restart the counter

}

*/

motor.loopFOC(); // main FOC algorithm function

motor.move();

command.run();

} // End loop

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬End_loop▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬