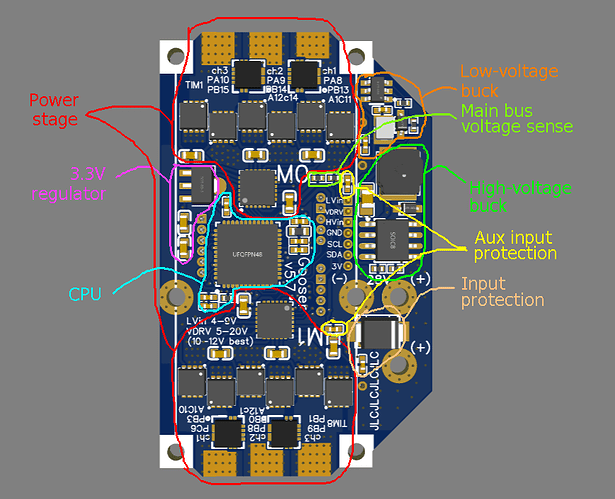

I hacked up another board to just add another driver output, for a stepper motor instead of 3 phase bldc. I am the first to say that there is a major problem with everything everyone publishes being a hackjob that is only marginally useful to anyone else, but unfortunately the economics are not something I am immune to more than anyone else. My priority is to get something that works, then I can improve it later.

This does at least integrate the wisdom that has been accumulated on the good components and so on. However I did not have time to beef up the current capacity of various routes. That would have to be left for another time, I prersonally only need like 3 amps so I can’t spend much time on that.

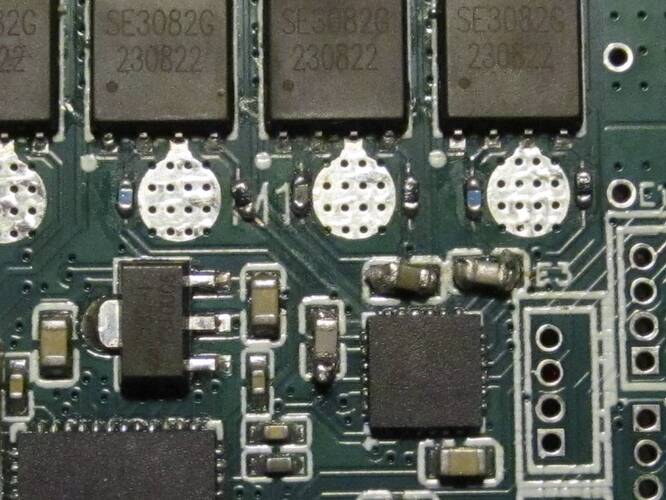

The previous version of this board was non functional due to a severe noise issue. Same as it’s predecessor the lepton. I added 10 ohm snubber resistors to the mosfet gates and an RC filter after the RFI filter to hopefully solve this issue. The B-g431-esc1 board works fine so I don’t believe it’s impossible to get this noise issue solved without extremely expensive mosfet drivers.

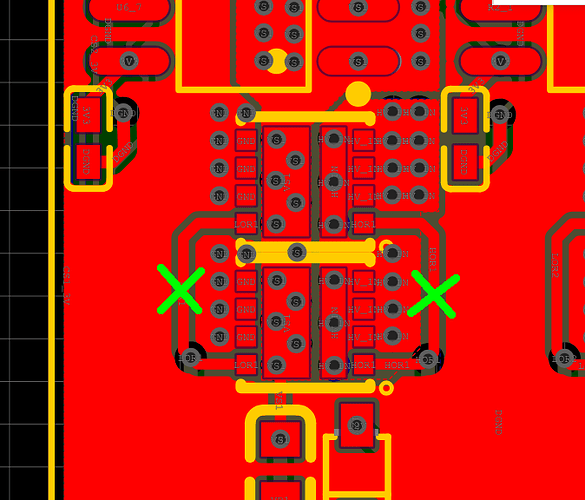

Can anyone spot any issues that would prevent this board from driving a 2 phase stepper motor so I can fix it before fabrication?

I know it’s hard to get people to agree on a single board to use as a flagship board but remember it doesn’t have to fit all purposes. We’ve disussed this in the past and a board like this can meet 90% of needs and it’s pretty silly we don’t have one yet. Everyone is always way back at the starting line every time we need a motor driver board. We should have a reasonably usable one that suits the basic things people often come into the forum needing to do. The simplefoc flagship board that’s currently available really doesn’t suit most needs.