Not so simple, but if you have access to a laser cutter or CNC is should be possible. I think the most difficult part is attaching and aligning the shifter/derailleur. Hmm, you also need some spring tension on the chain… it will be a complete rebuild of the drivetrain.

Hehe, this is an understatement. It’s a cheap motor but efficiencies are probably around 70 to 80%. That’s a guess.

I was just throwing things at the proverbial wall. You can ignore it.

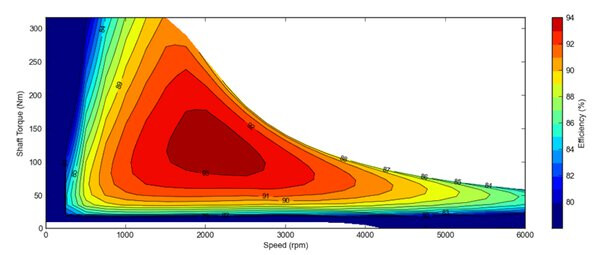

Yes, it is possible. Without the efficiency curves you cannot tell. That’s why I prefer MAD motors because you get the curves, which will remove the risk.

I’m not sure even where to start because these are empirically derived from a dynamometer, where they hook up a motor to a stand with a propeller and measure the thrust. I would say it’s not realistic and worth the effort.

This is a typical efficiency topo-map.

As you could see the only way to derive it is empirical. You will need a dynamometer.

Better pay for a motor where the efficiency is given to you by the manufacturer.