I was biting my tongue and not saying anything because I didn’t want to distract from efforts on the Lepton. However I’m impatient, my supply of low cogging motors just evaporated and this reaffirms the importance of a good quality, general purpose motor driver, which I could at least have some hope of implementing some kind of anti cogging feature in.

Given the issues thus far with the Lepton, I have to admit it does not look like finish line of my journey that I am frankly way over budget and overtime on to begin with…

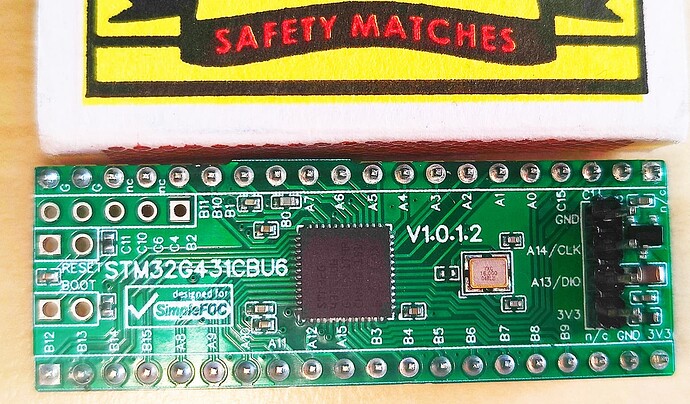

The flash memory is really small, and there are a lot of issues with compatibility with the Arduino ecosystem.

There are a couple other minor issues, and it’s clear that the code base also needs more effort (always lots to do, no ragging on those who have already done stuff, just that still more appears to be needed).

There is no way I can economically undertake this myself, and it’s not sensible to try. I propose a concerted community effort to make a system that is a successor to the Lepton. I am thinking:

-

the RP2040 could be a good choice? JLCPCB has it in stock. There is already some effort that has been done on getting SimpleFOC to run on it, apparently. It is well supported by arduino, the RBPI foundation is good stuff, it will be around in the future, is easy to interface to and program. It’s fast, has lots of memory and can be used in many other contexts. To be honest, for my project I have considered using a Pico board and just making a custom 6 pin pwm stage and encoder and soldering the stuff all together, but it wouldn’t be any better and we do have the capacity to get custom boards made relatively cheaply.

-

I would make it so you can highjack the PWM stage if you want. Right now I really wish I could do that so I could test and debug things. Also the PWM stage has other uses, if the board becomes common it would be best if it is multi use.

-I would break out more of the microcontroller pins, they might be useful for someone. -

I would use standard 2.54 mm pitch connectors, I know they take more space, but you can use dupont connectors, screw terminals, some kinds of molex, we could even make it so it plugs into a solderless breadboard (two breadboards side by side is a good hack for accommodating very wide boards). That really helps with prototyping and getting things done quickly.

-have at least one indicator LED for debugging and end use. People are going to be customizing the code and using it in a larger context to make what they need.

-someone suggested making it so you can flood certain areas with solder manually to reach the potential that the mosfets have. If things can be arranged so a tinned pad is the top side of the relevant areas so you don’t even have to scratch any stuff off that would be awesome.

-The Mosquito has a spot on the back for a magnetic angle sensor. Valentine noted the magnetic field of the high current could interfere, however I think that it would be very small at low currents, so it would be good to leave some pads for an angle sensor, as with the Mosquito. As soon as the sensor is off the board, you need to connect, mount, the whole assembly gets bigger and more expensive. If you only need a little current, and the board is carefully laid out, I think it would be useful for some people, and having the pads there is practically free, yeah? I also suggest that the issues caused by interference of the magnetic field could be compensated for, potentially, possibly by using some kind of calibration routine, as it seem to me the distortions would be similar to cogging.

- current sense might not be a bad idea, or at least have the pads for it. There are some great current sense ICs Also some extremely crude sensing could be done just with the ADC and a sense resistor, it seems to me this would have some uses, you can check to see if the voltage of the supply isn’t what you thought, or calculate the approximate resistance of the coils or whatever. Possibly also the inductance and other characteristics, which apparently is important in high quality algorithms for FOC control, although I don’t understand this much, I can see what happens when the figures are set wrong with the MCF8316 board I have, the smoothness and quality of the drive clearly deteriorates.

I apologize if it seems like I am bailing on the Lepton before giving it a chance, but even if it can work in a basic mode, is there room in the flash to add anti cogging features, for instance? It doesn’t seem very general purpose or future-proof.

If we come together and come up with a promising board and sensor combo, respectably compatible with the code base, I’m willing to get a bunch of them made and then mail them out for free to others who want some.