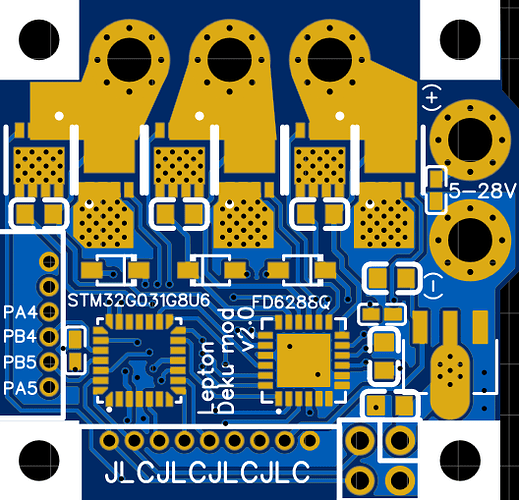

Continuing from here Lepton v2 revised design --- tested working 30V / 80A MOSFETs - #43 by dekutree64

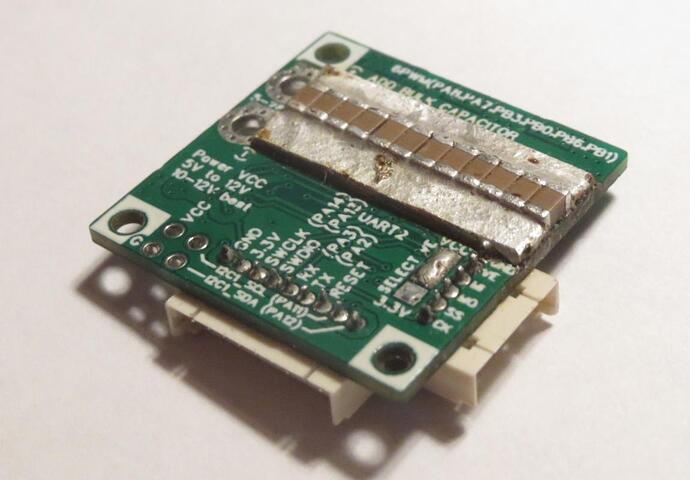

My boards have arrived, and they are ever so lovely. Unfortunately I don’t have the 9 pin female cables to connect to them with, so I can’t actually test just yet unless I want to try soldering wires to the 1.25mm pitch pins on the underside (I might).

I do have 6 pin cables though, and can confirm that both the XKB connectors and HCTL are compatible with cheap cables off ebay.

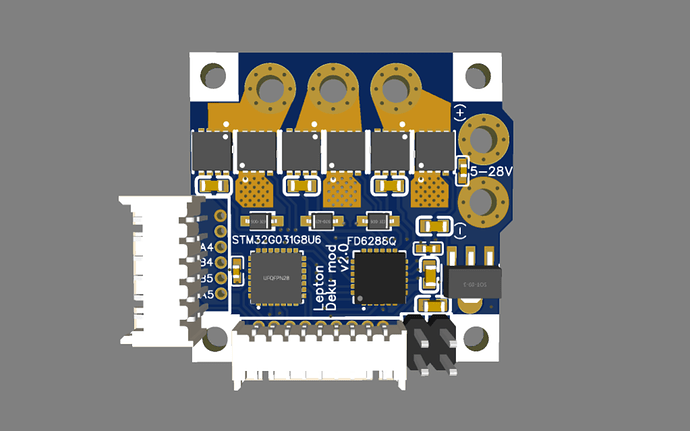

Here is what the front and back look like as they come from JLCPCB.

Then to boost the current capacity, take a piece of 2mm copper wire and hammer it out to about 3x1mm rectangular.

Clip off a couple pieces, bend them as flat as possible, and then sand to perfection. I used my trusty extra-extra-coarse DMT Dia-sharp stone.

Then tin them with solder while holding with pliers, apply some flux to the board, and stick the copper bars as well as 12 ceramic capacitors in place (now you can see why I put the JLC order number where I did ![]() ). Getting the first copper bar tacked down was a bit tricky because it wants to slide around in the flux and/or molten solder. Once that’s done, you can use tweezers to push the other bar and capacitors up against it while soldering. Add more solder on the capacitors, and then reheat the first bar to make sure it’s fully seated.

). Getting the first copper bar tacked down was a bit tricky because it wants to slide around in the flux and/or molten solder. Once that’s done, you can use tweezers to push the other bar and capacitors up against it while soldering. Add more solder on the capacitors, and then reheat the first bar to make sure it’s fully seated.

I was worried the transistors would fall off the front while I was soldering these large pieces on the back, but it seems my fears were unfounded. It’s easy to tell when the solder under the copper bar melts, so you can stop before the heat has time to soak through and hit melting temperature on the other side.

On the front side, I added some blobs of solder to help conduct current from the S2 pin of each transistor to the vias that go through to the ground rail. I touched the capacitor on the far right with the soldering iron and it got sucked into the blob, so I had to re-solder it in its original location. No harm done.

So there it is, exactly as I had envisioned! Why isn’t this the standard method of constructing motor drivers? 4 layer PCBs and 2oz+ copper are so expensive, yet here you can have even heavier conductors with just a little bit of manual soldering. I’m already having visions of doing it with these monster TOLL-8 MOSFETs and playing this on loudspeakers in the back yard while I test it https://www.youtube.com/watch?v=ERKnkHq-6XA

Heck, you could even load pre-made copper bars on a pick-and-place machine and solder them with paste like any other SMD component. Better still, use finned heatsinks as the conductors ![]()

Thank you again to Valentine for providing the basic layout and component selection, and answers to my many questions ![]() Such a liberating feeling to add PCB design to my skillset.

Such a liberating feeling to add PCB design to my skillset.