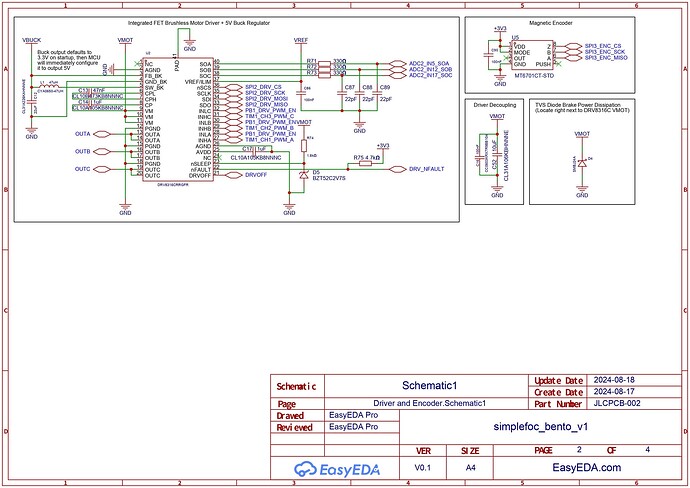

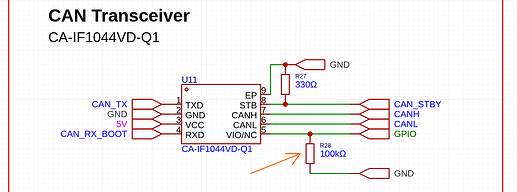

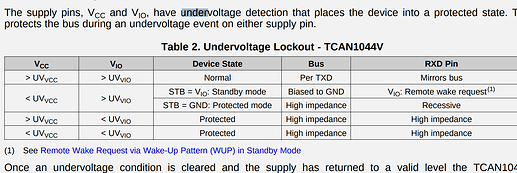

You’re right, I did not check the datasheet of the CAN Transceiver - the RXD pull-up would indeed be an issue. That’s a bummer, I think then you would need an additional component like a buffer with active low EN function so that you could switch off the connection between transceiver and MCU completely. The CAN-STB signal would then switch both the transceiver and the buffer to disable CAN and the connection at the same time.

Fair enough… there has even been a SimpleFOC dynamixel implementation which you can find in the forum…

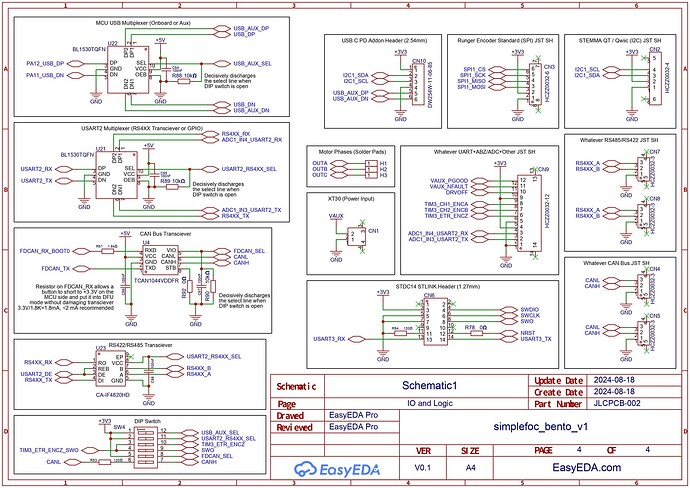

Personally I’m just not a big fan of RS485 compared to CAN or ethernet/WiFi/BT. But that’s just my bias, probably.

Ok, makes sense, and the LPUARTs are in the PinMaps, so they should work. It makes me a bit nervous because some of the other LP-peripherals aren’t supported in Arduino.

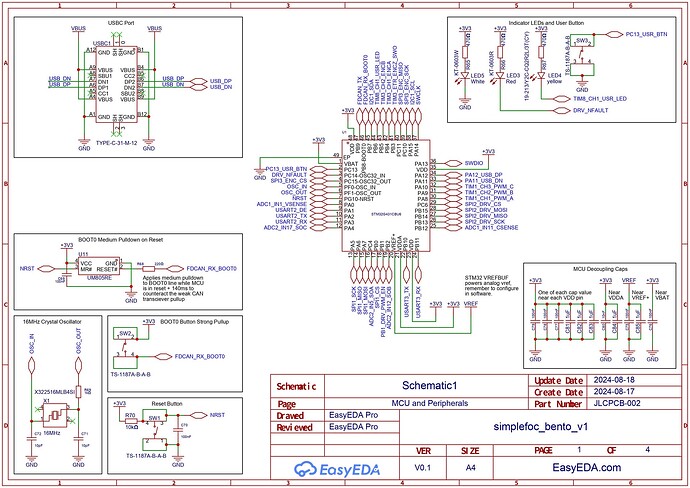

Personally, I much prefer SWD for programming the STM32s. STLink V3s are faster at programming than other options, in my experience, and it always works without having to reboot while holding BOOT0.

The STLink VCP serial connection remains active even when the MCU reboots, so the serial console is much more useable and you don’t always miss the boot messages due to serial reconnects. Debugging is directly supported on the same connection.

Its just the most convenient way to work with these chips, I find. But of course you do have to invest in a ST-Link. But compared to all the other vendors, ST-Micro is super-fair with their programmers pricing. I think they’re even selling them below cost.

That’s a good question. After many iterations I now do it like this: I connect 3.3V via a solder (or header) jumper, normally closed. This way you can directly use it to connect I2C target devices like sensors or IMUs, and they’ll be powered with 3.3V.

If on the other hand you want to use the I2C port in target device mode, to control the driver from your RPi for example, then you cut the the 3.3V connection so as not to back-power the RPi.

Personally I never use 5V really, and there are plenty of 3.3V devices available. But should people need 5V there are StemmaQT compatible level shifters they can just plug in-between.

Ok, I get it now. It’s what I meant by saying you could not use them at the same time, but multiplexing them in this way should work fine. It will be a bit involved in terms of the code compared to having an extra pin free though ![]()

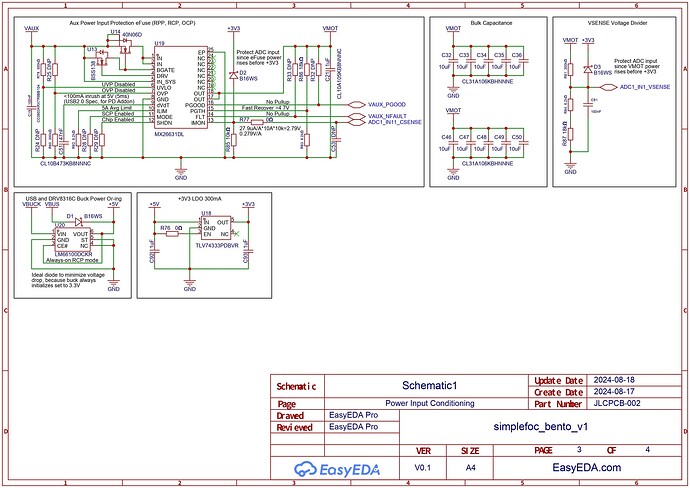

I think it will be possible, but the result for the user will depend a lot not just on the driver board and its firmware, but also where it gets plugged into. MacBooks won’t recognize it as an approved device, and won’t give it more than 7.5W and 5V. Plugging it to a notebook PSU will give it enough juice, but then it won’t be possible to use the DFU. Probably users with a powerful USB-PD Hub will have the best experience.