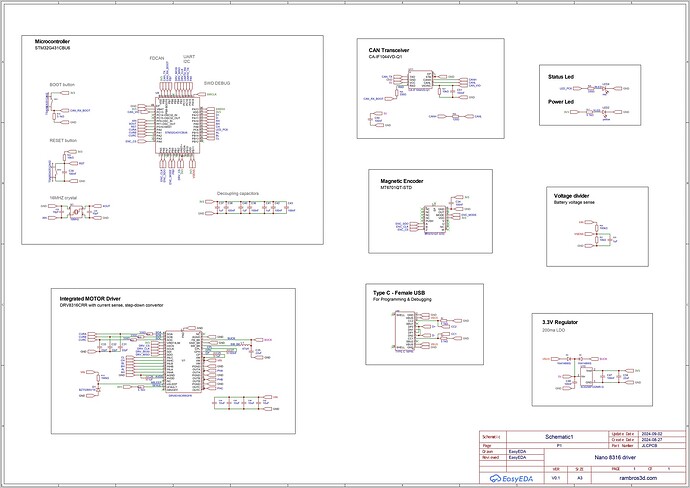

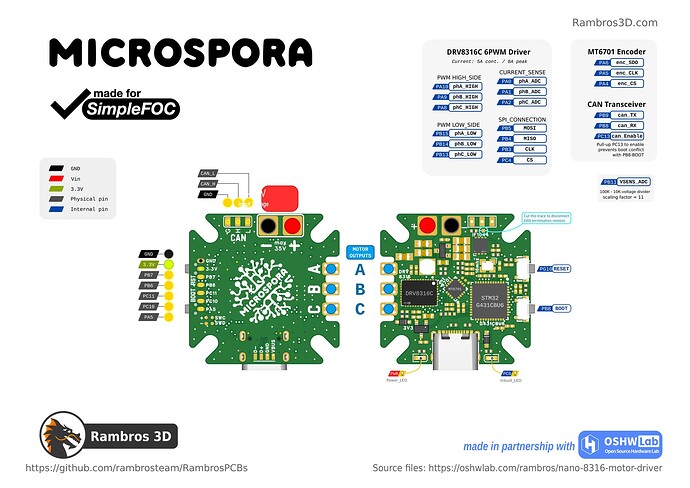

Here’s the schematic:

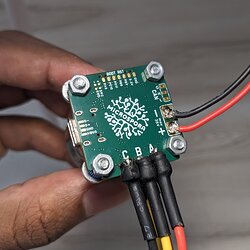

The board will be used to control this A2212 motor. We use these type of motors in our 3D printed RC vehicles. (trucks, cars, excavators…)

Interfaces:

- CANBUS

- UART

- I2C

- PWM

I will mostly use PWM for now. The rest are just for testing purpose.

Notes:

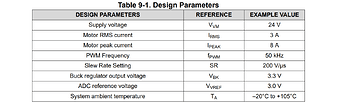

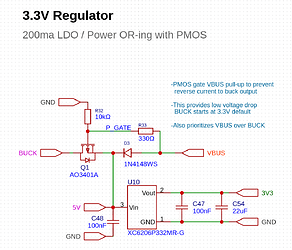

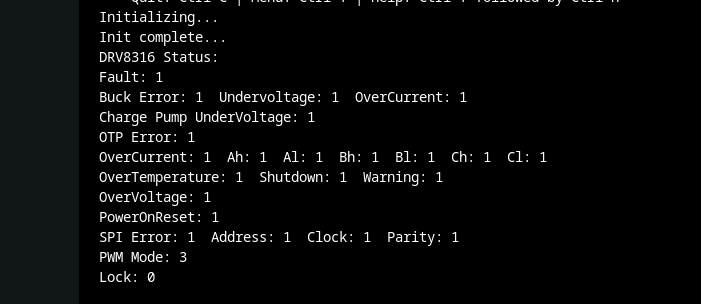

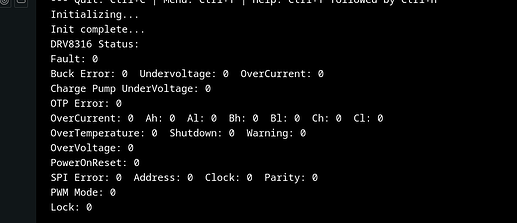

- DRV8316 motor driver wired with 6PWM. Used a 5V zener as vref to provide pullup for NSLEEP

- VIO of IF1044VD CAN transceiver connected to PC13 to hopefully prevent conflict of RXD pin with PB8-BOOT0

- 10k pull-up for NRST, don’t want capacitative touch for reset

@dekutree64

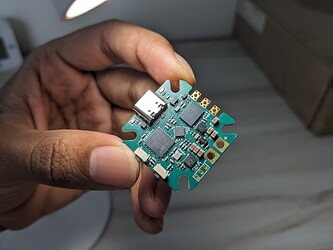

@dekutree64 - Planning to go with a 1.2mm 6-layer board and economic assembly

This will be my first PCB using a STM32 MCU. My previous PCBs were limited to ESP32 series and RP2040

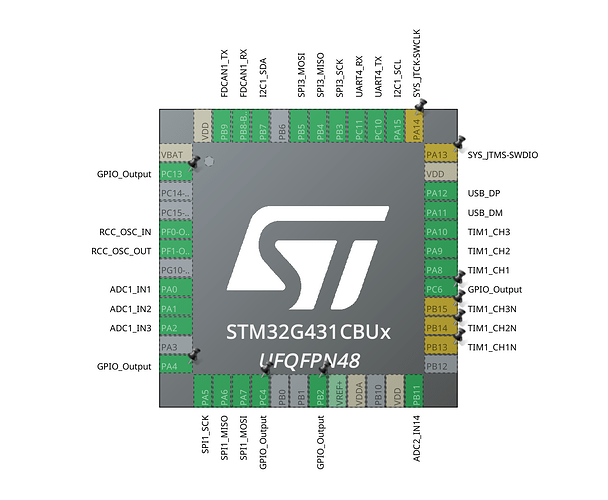

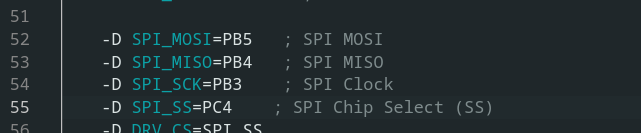

I used the CubeMX to determine the pins - PWM, I2C, UART, FDCAN

I would like to program this directly from USB with Arduino IDE. Do I need to use STM32Cube IDE or ST-Link to configure this MCU for the first time? Or can we directly start using this board from the Arduino IDE.

Thank you everyone