Hi Runger,

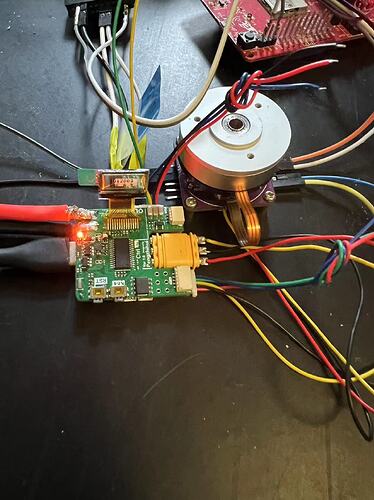

The board is designed by a maker, I am studying with his board.

https://github.com/peng-zhihui/Ctrl-FOC-Lite

He did many cool diy design there.

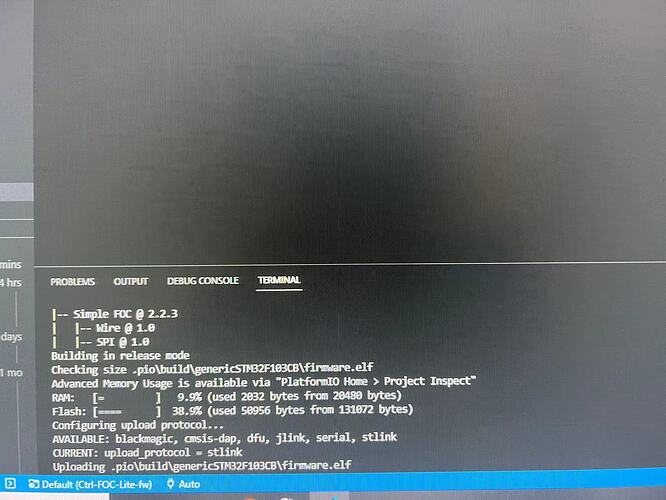

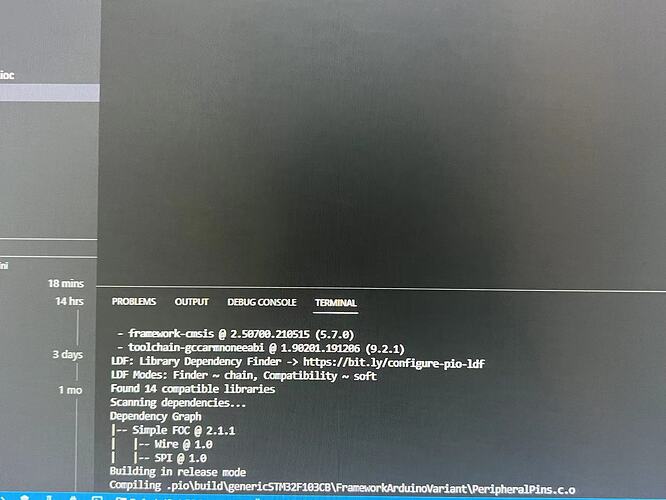

I re-install the platformio with new packages, using 2.2.3 version dev code, issue is the same, still no debug log output…

Here is my code.

#include <SimpleFOC.h>

#include <Arduino.h>

// Motor instance

BLDCMotor motor = BLDCMotor(7);

BLDCDriver3PWM driver = BLDCDriver3PWM(PB_4, PB_5, PB_0, PB_12);

Encoder encoder = Encoder(PA_8, PA_9, 1000);

// Interrupt routine intialisation

// channel A and B callbacks

void doA()

{ encoder.handleA(); }

void doB()

{ encoder.handleB(); }

void doI()

{ encoder.handleIndex(); }

// current sensor

InlineCurrentSense current_sense = InlineCurrentSense(0.01f, 50.0f, A0, A1);

// angle,velocity set point variable

float target_velocity = 0;

float target_angle = 0;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char *cmd)

{ command.scalar(&target_velocity, cmd); }

void doMotor(char* cmd)

{ command.motor(&motor, cmd); }

void setup()

{

// use monitoring with serial

Serial.begin(115200);

SimpleFOCDebug::enable(&Serial);

_delay(100);

// initialize encoder sensor hardware

encoder.init();

encoder.enableInterrupts(doA, doB);

// link the motor to the sensor

motor.linkSensor(&encoder);

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

// link current sense and the driver

// current_sense.linkDriver(&driver);

// initialise magnetic sensor hardware

//current_sense.init();

// link the motor to the sensor

//motor.linkCurrentSense(¤t_sense);

// aligning voltage [V]

motor.voltage_sensor_align = 1.5;

// if you are not using aligning voltage, you can set current limitation

motor.phase_resistance = 0.35; // [Ohm]

//motor.phase_resistance = 3.5; // [Ohm]

// index search velocity [rad/s]

// motor.velocity_index_search = 3;

// motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set motion control loop to be used

//motor.controller = MotionControlType::velocity;

motor.torque_controller = TorqueControlType::voltage;

// motor.controller = MotionControlType::torque;

// set the inital target value

// motor.target = 0.5;

// default voltage_power_supply

// internal res is 0.35 ou maximum current is 2A

// maximum volts is 0.7

// this is used for open loop

// motor.voltage_limit = 0.7;

// maximal velocity of the position control

motor.velocity_limit = 10;

// motor.target = 0.1; // Volts

// contoller configuration

// default parameters in defaults.h

// velocity PI controller parameters

motor.PID_velocity.P = 0.012;

motor.PID_velocity.I = 0.04;

//motor.PID_velocity.D = 0.001;

// jerk control using voltage voltage ramp

// default value is 300 volts per sec ~ 0.3V per millisecond

motor.PID_velocity.output_ramp = 1000;

// velocity low pass filtering time constant

motor.LPF_velocity.Tf = 0.01;

motor.voltage_limit = 0.8;

motor.current_limit = 0.5; // Amps

// angle P controller

motor.P_angle.P = 23;

motor.P_angle.D = 0.01;

// comment out if not needed

motor.useMonitoring(Serial);

motor.monitor_downsample = 1; // setting sample rate, can up to 100+

motor.monitor_variables = _MON_TARGET | _MON_CURR_Q | _MON_CURR_D | _MON_VEL | _MON_ANGLE;

// invert phase b gain

// current_sense.gain_b *=-1;

// skip alignment

// current_sense.skip_align = true;

// initialize motor

motor.init();

// align encoder and start FOC

motor.initFOC();

motor.target = 0.5;

// 订阅电机至commander

command.add('M', doMotor,"motor");

// add target command T

// command.add('T', doTarget, "target_velocity");

Serial.println("Motor ready.");

Serial.println("Set the target using serial terminal:");

_delay(300);

}

void loop()

{

// main FOC algorithm function

// the faster you run this function the better

// Arduino UNO loop ~1kHz

// Bluepill loop ~10kHz

motor.loopFOC();

// Motion control function

// velocity, position or voltage (defined in motor.controller)

// this function can be run at much lower frequency than loopFOC() function

// You can also use motor.move() and set the motor.target in the code

// motor.move(target_velocity);

motor.move();

// function intended to be used with serial plotter to monitor motor variables

// significantly slowing the execution down!!!!

motor.monitor();

// user communication

command.run();

// test current

//PhaseCurrent_s currents = current_sense.getPhaseCurrents();

//float current_magnitude = current_sense.getDCCurrent();

//Serial.print(currents.a * 1000); // milli Amps

//Serial.print("\t");

//Serial.print(currents.b * 1000); // milli Amps

//Serial.print("\t");

//Serial.print(currents.c * 1000); // milli Amps

//Serial.print("\t");

//Serial.println(current_magnitude * 1000); // milli Amps

//test encoder

//encoder.update();

// display the angle and the angular velocity to the terminal

//Serial.print(encoder.getAngle());

//Serial.print("\t");

//Serial.println(encoder.getVelocity());

}

Here is config file

[env:genericSTM32F103CB]

platform = ststm32

board = genericSTM32F103CB

framework = arduino

upload_protocol = stlink

debug_tool = stlink

upload_flags = -c set CPUTAPID 0x1ba01477

build_flags = -D SIMPLEFOC_STM32_DEBUG

lib_archive = false