Yes we were discussing it with @Antun_Skuric earlier today, please don’t use dev branch for now.

Huh huh, you’re using low-side current sensing right? ![]()

Yes

/*

SimpleFOC_STM32F405RGT6

odrive 3.6 - odesk 4.2

Hall sensor example code

This is a code intended to test the hall sensors connections and to demonstrate the hall sensor setup.

odrive_example_encoder.ino

https://github.com/simplefoc/Arduino-FOC/blob/dev/examples/hardware_specific_examples/Odrive_examples/odrive_example_encoder/odrive_example_encoder.ino

https://community.simplefoc.com/t/problems-with-custom-firmware-for-odrive-v3-5-using-simplefoc/2743

#include <Arduino.h>

#include <Wire.h>

https://github.com/simplefoc/Arduino-FOC/tree/master/examples/hardware_specific_examples/Odrive_examples

SoftwareSerial STM32F405RGT6

ODrive-fw-v0.5.6

https://github.com/odriverobotics/ODrive/releases

https://docs.odriverobotics.com/v/0.5.6/getting-started.html

Anti Spark Switch

IRFS7530TRL7PP

https://github.com/msglazer/Anti-Spark_Switch

*/

#include <Arduino.h>

#include <SimpleFOC.h>

#include <SimpleFOCDrivers.h>

#include <encoders/smoothing/SmoothingSensor.h>

//#define SIMPLEFOC_DISABLE_DEBUG

/*-D SIMPLEFOC_DISABLE_DEBUG*/

//M0

#define A_HALL1 PB4

#define A_HALL2 PB5

#define A_HALL3 PC9

//M0

#define M0_IA _NC // Pas dispo en A !

#define M0_IB PC0

#define M0_IC PC1

// Odrive M0 motor pinout

#define M0_INH_A PA8

#define M0_INH_B PA9

#define M0_INH_C PA10

#define M0_INL_A PB13

#define M0_INL_B PB14

#define M0_INL_C PB15

// M1 & M2 common enable pin

#define EN_GATE PB12

//Pole pair

#define PP 10

//Temp

#define M0_TEMP PC5

// Motor instance

BLDCMotor motor = BLDCMotor(PP);

BLDCDriver6PWM driver = BLDCDriver6PWM(M0_INH_A, M0_INL_A, M0_INH_B, M0_INL_B, M0_INH_C, M0_INL_C, EN_GATE);

// low side current sensing define

// 0.0005 Ohm resistor

// gain of 10x

// current sensing on B and C phases, phase A not connected

//LowsideCurrentSense currentSense = LowsideCurrentSense(0.0005f, 10.0f, M0_IA, M0_IB, M0_IC);

LowsideCurrentSense currentSense = LowsideCurrentSense(0.0005f, 30.0f, M0_IA, M0_IB, M0_IC);

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬Hall▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// Hall sensor instance

// HallSensor(int hallA, int hallB , int cpr, int index)

// - hallA, hallB, hallC - HallSensor A, B and C pins

// - pp - pole pairs

HallSensor sensor = HallSensor(A_HALL1, A_HALL2, A_HALL3, PP); // PP = xx aimants / 2 = pole pair

// Interrupt routine intialisation

// channel A and B callbacks

void doA() {

sensor.handleA();

}

void doB() {

sensor.handleB();

}

void doC() {

sensor.handleC();

}

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬SPI▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

/*

// SPI

#define SPI_MOSI PC11

#define SPI_MISO PC12

#define SPI_SCK PC10

#define M1_nCS PC14

*/

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬HardwareSerial_Serial1▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

#define PIN_SERIAL1_RX PA3

#define PIN_SERIAL1_TX PA2

#define SERIAL_PORT_HARDWARE Serial1

HardwareSerial Serial1(PIN_SERIAL1_RX, PIN_SERIAL1_TX); // RX, TX

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬USB_OTG_Serial▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// https://www.stm32duino.com/viewtopic.php?p=12540&hilit=USBD_VID#p12540

/*

USB OTG

USB_P ==> PA12 USART1_RTS USB_P

USB_N ==> PA11 USART1_CTS USB_N

-D PIO_FRAMEWORK_ARDUINO_ENABLE_CDC

;-D PIO_FRAMEWORK_ARDUINO_USB_LOWSPEED_FULLMODE ;This is not needed anymore, more in documentations.

-D USBCON

-D USBD_VID=0x0483

-D USBD_PID=0x5740

-D USB_MANUFACTURER="SimpleFOC"

-D USB_PRODUCT="\"SimpleFOC_STM32F405RGT6\""

-D HAL_PCD_MODULE_ENABLED

// https://github.com/stm32duino/Arduino_Core_STM32/blob/main/cores/arduino/WSerial.h

-DSERIAL_UART_INSTANCE=1

-D HAL_OPAMP_MODULE_ENABLED

-DSIMPLEFOC_STM32_DEBUG

-DPIO_FRAMEWORK_ARDUINO_ENABLE_CDC

-DUSBD_USE_CDC

-DUSBCON

*/

#include <HardwareSerial.h>

HardwareSerial SerialUSB(USART1); // Enable USB Serial

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬Commander▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// https://docs.simplefoc.com/communication

// instantiate the commander

Commander command = Commander(Serial1);

// motor SimpleFOCStudio ==> M

void doMotor(char* cmd) {

command.motor(&motor, cmd);

//command.target(&motor, cmd); // ok

//command.motion(&motor, cmd);

}

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬SmoothingSensor▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// wrapper instance SmoothingSensor

// https://github.com/simplefoc/Arduino-FOC-drivers/blob/dev/examples/encoders/smoothing/smoothing.ino

SmoothingSensor smooth(sensor, motor);

int sensorTYPE = 0;

void enableSmoothing(char* cmd) {

motor.linkSensor((Sensor*)&smooth);

sensorTYPE = 0;

}

void enableSensor(char* cmd) {

motor.linkSensor((Sensor*)&sensor);

sensorTYPE = 1;

}

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬AUX▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

//AUX_L PB10

//AUX_H PB11

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬readSensor▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// https://github.com/simplefoc/Arduino-FOC/blob/dev/examples/utils/sensor_test/generic_sensor/generic_sensor.ino

// https://github.com/stm32duino/Arduino_Core_STM32/blob/c83db2e4f6b4b8d3bbedce67d2156a58023bc432/variants/STM32F4xx/F405RGT_F415RGT/PeripheralPins.c#L43

#define HAL_ADC_MODULE_ENABLED

// PA_1 // PA_1_ALT1 // PA_1_ALT2

#define PIN_POT1 PA_1_ALT2 // PA1 On utilise

int valPOT;

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬setup▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

void setup() {

//▬▬▬▬▬▬▬▬▬▬▬▬sensor_analog▬▬▬▬▬▬▬▬▬▬▬▬

//pinMode(PIN_POT1, INPUT_PULLUP);

pinMode(PIN_POT1, INPUT_ANALOG);

//analogReadResolution(8); // 12

//▬▬▬▬▬▬▬▬▬▬▬▬CAN▬▬▬▬▬▬▬▬▬▬▬▬

//CAN_R PB8

//CAN_D PB9

//▬▬▬▬▬▬▬▬▬▬▬▬AUX▬▬▬▬▬▬▬▬▬▬▬▬

//AUX_L PB10

//AUX_H PB11

//▬▬▬▬▬▬▬▬▬▬▬▬Temp▬▬▬▬▬▬▬▬▬▬▬▬

//pinMode(M0_TEMP, INPUT_PULLUP); // M0_TEMP PC5

//pinMode(AUX_TEMP, INPUT_PULLUP); // AUX_TEMP PA5

//▬▬▬▬▬▬▬▬▬▬▬▬GPIO1/GPIO2/GPIO3/GPIO4▬▬▬▬▬▬▬▬▬▬▬▬

//pinMode(PA0, OUTPUT); // GPIO1 ADC123_IN0 UART4_TX

//digitalWrite(PA0, LOW); // HIGH/LOW

//pinMode(PA1, OUTPUT); // GPIO2 ADC123_IN1 UART4_RX

//digitalWrite(PA1, LOW); // HIGH/LOW

/*

// PA2 utilisé pour RX/TX avec SoftwareSerial

//pinMode(PA2, OUTPUT); // GPIO3 ADC123_IN2 USART2_TX

//digitalWrite(PA2, LOW); // HIGH/LOW

// PA3 utilisé pour RX/TX avec SoftwareSerial

//pinMode(PA3, OUTPUT); // GPIO4 ADC123_IN3 USART2_RX

//digitalWrite(PA3, LOW); // HIGH/LOW

*/

//▬▬▬▬▬▬▬▬▬▬▬▬HardwareSerial_Serial1▬▬▬▬▬▬▬▬▬▬▬▬

pinMode(PIN_SERIAL1_RX, INPUT_PULLUP); // sur GPIO4 ==> PA3

pinMode(PIN_SERIAL1_TX, OUTPUT); // sur GPIO3 ==> PA2

Serial1.begin(921600); // 921600 115200 230400

_delay(1000);

//▬▬▬▬▬▬▬▬▬▬▬▬USB_OTG_Serial▬▬▬▬▬▬▬▬▬▬▬▬

SerialUSB.begin(115200);

//▬▬▬▬▬▬▬▬▬▬▬▬driver▬▬▬▬▬▬▬▬▬▬▬▬

// pwm frequency to be used [Hz]

driver.pwm_frequency = 20000; // 20000 max STM32

driver.voltage_power_supply = 24.0f; // power supply voltage [V]

driver.voltage_limit = 20.0f; // Max DC voltage allowed - default voltage_power_supply

/*

https://docs.simplefoc.com/bldcdriver6pwm

Le paramètre de la zone morte est défini comme la quantité du cycle de service qui est réservée

entre les changements du mosfet actif. Chaque fois que le côté haut/bas est désactivé

et que le côté bas/haut est activé, la moitié de la zone morte est injectée.

Ce paramètre est équivalent au temps mort,

le temps mort peut être calculé comme suit : dead_time = 1/pwm_frequency*dead_zone

*/

// 1/20000*dead_zone=?

driver.dead_zone = 0.05f; // dead_zone [0,1] - default 0.02f - 2%

driver.init();// driver init

motor.linkDriver(&driver); // link the motor and the driver

//▬▬▬▬▬▬▬▬▬▬▬▬Current▬▬▬▬▬▬▬▬▬▬▬▬

// https://docs.simplefoc.com/low_side_current_sense

currentSense.linkDriver(&driver); // link the driver

//▬▬▬▬▬▬▬▬▬▬▬▬HALL sensor▬▬▬▬▬▬▬▬▬▬▬▬

sensor.pullup = Pullup::USE_EXTERN; // check if you need internal pullups

sensor.init(); // initialise encoder hardware

sensor.enableInterrupts(doA, doB, doC); // hardware interrupt enable

motor.linkSensor(&sensor); //

// SmoothingSensor

// https://github.com/simplefoc/Arduino-FOC-drivers/blob/dev/examples/encoders/smoothing/smoothing.ino

smooth.phase_correction = -_PI_6; // set SmoothingSensor phase correction for hall sensors

//motor.linkSensor(&smooth);// link the SmoothingSensor to the motor

_delay(1000);

//▬▬▬▬▬▬▬▬▬▬▬▬mode▬▬▬▬▬▬▬▬▬▬▬▬

// set torque mode

// https://docs.simplefoc.com/foc_current_torque_mode

motor.torque_controller = TorqueControlType::foc_current; // foc_current || dc_current || voltage

motor.controller = MotionControlType::velocity; // angle velocity torque // Control loop type

// choose FOC modulation

// FOCModulationType::SinePWM; (default)

// FOCModulationType::SpaceVectorPWM;

// FOCModulationType::Trapezoid_120;

// FOCModulationType::Trapezoid_150;

motor.foc_modulation = FOCModulationType::SinePWM; // pwm modulation settings

motor.modulation_centered = 1; // 1

//▬▬▬▬▬▬▬▬▬▬▬▬ALL_PID▬▬▬▬▬▬▬▬▬▬▬▬

// velocity PID

motor.PID_velocity.P = 0.075f; // 0.08f

motor.PID_velocity.I = 0.8f; // 0.8f

motor.PID_velocity.D = 0.0001; // 0.001f

//motor.PID_velocity.output_ramp = 1000.0f;

//motor.PID_velocity.limit = 5.0f; // ? current_limit [Amps] // https://community.simplefoc.com/t/setting-current-limits-in-main-loop/1972

//motor.LPF_velocity.Tf = 0.001f; //0.01f // Low pass filtering time constant

// angle PID

motor.P_angle.P = 30.0f; // 30.0

//motor.P_angle.I = 0.0f;

//motor.P_angle.D = 0.0f;

//motor.P_angle.output_ramp = 10000.0f; // 10000.0

//motor.P_angle.limit = 120.0f; // ? velocity_limit [rad/s]

//motor.LPF_angle.Tf = 0.001f; // Low pass filtering time constant

// current q PID

motor.PID_current_q.P = 0.05f; // 0.05f

motor.PID_current_q.I = 30.0f; // 50.0f

//motor.PID_current_q.D = 0.001f; //0.001f

//motor.PID_current_q.output_ramp = 1000.0f; //1000.0f

//motor.PID_current_q.limit = 3.0f; // https://community.simplefoc.com/t/setting-current-limits-in-main-loop/1972

//motor.LPF_current_q.Tf = 0.005f; // 0.005f Low pass filtering time constant

// current d PID

motor.PID_current_d.P = 0.05f; // 0.05f

motor.PID_current_d.I = 30.0f; // 50.0f

//motor.PID_current_d.D = 0.001f; //0.001f

//motor.PID_current_d.output_ramp = 1000.0f; //1000.0f

//motor.PID_current_d.limit = 3.0f; // https://community.simplefoc.com/t/setting-current-limits-in-main-loop/1972

//motor.LPF_current_d.Tf = 0.005f; // 0.005f Low pass filtering time constant

//▬▬▬▬▬▬▬▬▬▬▬▬Limits▬▬▬▬▬▬▬▬▬▬▬▬

motor.velocity_limit = 120.0f; // [rad/s] (120[rad/s] ==> ~1200[RPM])

motor.voltage_limit = 0.5f * driver.voltage_limit; // [Volts] // Calcul ==> 5.57[Ohms]*1.0[Amps]=5,57[Volts] // [V] - if phase resistance not defined

// https://www.digikey.fr/fr/resources/conversion-calculators/conversion-calculator-ohms

motor.current_limit = 5.0f; // Current limit [Amps] - if phase resistance defined

//motor.phase_resistance = 0.5f; // [Ohms] // motor phase resistance // I_max = V_dc/R

motor.phase_resistance = 3.84f; // [Ohms] // motor phase resistance // I_max = V_dc/R

// https://docs.simplefoc.com/hall_sensors#hardware-external-interrupt

sensor.velocity_max = 1200; // 1000rad/s by default ~10,000 rpm // maximal expected velocity

motor.KV_rating = 120; // [rpm/Volt] - default not set // motor KV rating [rpm/V]

// commenter les 2 ci-dessous pour avoir le test au demarrage

motor.zero_electric_angle = 2.094396f; // zero_electric_angle

motor.sensor_direction = Direction::CCW; // Cw/CCW // direction

//▬▬▬▬▬▬▬▬▬▬▬▬SimpleFOCDebug▬▬▬▬▬▬▬▬▬▬▬▬

// https://docs.simplefoc.com/debugging

SimpleFOCDebug::enable(NULL);

//SimpleFOCDebug::enable(&mySerial);

//▬▬▬▬▬▬▬▬▬▬▬▬motion_downsample▬▬▬▬▬▬▬▬▬▬▬▬

/*

Pour de nombreuses applications de contrôle de mouvement, il est judicieux d'exécuter

plusieurs boucles de contrôle de couple pour chaque boucle de contrôle de mouvement.

Cela peut avoir un impact important sur la fluidité et peut fournir de meilleures performances à grande vitesse.

C'est pourquoi cette bibliothèque permet une stratégie de sous-échantillonnage très simple pour la fonction move()

qui est définie à l'aide du paramètre

La stratégie de downsampling fonctionne de manière très simple, même si la fonction motor.move()

est appelée dans chaque boucle arduino, elle ne sera exécutée qu'à chaque fois que motor.motion_downsample sera appelé.

Ce paramètre est optionnel et peut être configuré en temps réel.

*/

motor.motion_downsample = 0; // 0 https://docs.simplefoc.com/bldcmotor

//▬▬▬▬▬▬▬▬▬▬▬▬init▬▬▬▬▬▬▬▬▬▬▬▬

motor.init(); // initialise motor

//▬▬▬▬▬▬▬▬▬▬▬▬linkCurrentSense▬▬▬▬▬▬▬▬▬▬▬▬

// https://docs.simplefoc.com/low_side_current_sense

currentSense.init(); // init the current sense

// If monitoring is enabled for the motor during the initFOC the monitor will display the alignment status:

// 0 - fail

// 1 - success and nothing changed

// 2 - success but pins reconfigured

// 3 - success but gains inverted

// 4 - success but pins reconfigured and gains inverted

// If you are sure in your configuration and if you wish to skip the alignment procedure you can specify set the skip_align flag before calling motor.initFOC():

// skip alignment procedure

currentSense.skip_align = true; // true false

/*

// invert phase b gain

//currentSense.gain_a *=-1;

currentSense.gain_b *= -1;

currentSense.gain_c *= -1;

*/

/*

// default values of per phase gains

float shunt_resistor = 0.0005f;

float gain = 30.0f;

//currentSense.gain_a = 1.0 / shunt_resistor / gain;

currentSense.gain_b = 1.0 / shunt_resistor / gain;

currentSense.gain_c = 1.0 / shunt_resistor / gain;

*/

motor.linkCurrentSense(¤tSense);

//▬▬▬▬▬▬▬▬▬▬▬▬initFOC▬▬▬▬▬▬▬▬▬▬▬▬

motor.initFOC(); // init FOC

//▬▬▬▬▬▬▬▬▬▬▬▬command▬▬▬▬▬▬▬▬▬▬▬▬

// https://docs.simplefoc.com/commander_interface

// add the motor to the commander interface

command.decimal_places = 4; // default 3

command.add('M', doMotor, "motor exemple ==> M10"); // The letter (here 'M') you will provide to the SimpleFOCStudio

//▬▬▬▬▬▬▬▬▬▬▬▬enableSmoothing▬▬▬▬▬▬▬▬▬▬▬▬

// add smoothing enable/disable E0|F0

command.add('E', enableSmoothing, "enable smoothing ==> E0 smoothing");

command.add('F', enableSensor, "enable sensor ==> F0 sensor");

//▬▬▬▬▬▬▬▬▬▬▬▬command ==> VerboseMode▬▬▬▬▬▬▬▬▬▬▬▬

// case VerboseMode::nothing:

// case VerboseMode::on_request:

// case VerboseMode::user_friendly:

// case VerboseMode::machine_readable:

command.verbose = VerboseMode::nothing; // disable commander output to serial

//▬▬▬▬▬▬▬▬▬▬▬▬target▬▬▬▬▬▬▬▬▬▬▬▬

motor.target = 0;

_delay(1000);

} // End setup

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬End_setup▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬loop▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

float valVEL;

float sensor_getAngle;

float valWATTS;

String toSEND;

long timestamp = millis();

// current https://docs.simplefoc.com/inline_current_sense

PhaseCurrent_s current;// getPhaseCurrents

float current_magnitude;

int old_motor_enabled;

float memory_max_current = motor.current_limit;

#include "BLDCMotor.h"

void loop_debug() {

current = currentSense.getPhaseCurrents();

current_magnitude = currentSense.getDCCurrent(); // https://docs.simplefoc.com/inline_current_sense#example-code

bool is_enabled = motor.enabled;

command.run();

if (motor.enabled && !is_enabled) { // if we have a change in enabled state, reset the PID

motor.PID_velocity.reset();

motor.PID_current_q.reset();

motor.PID_current_d.reset();

}

if (!motor.enabled) { // in the disabled state, update the target to match the current velocity

motor.target = motor.shaft_velocity;

}

motor.move();

motor.loopFOC(); // loopFOC() after move, to make sure new targets are set

}

void loop() {

motor.loopFOC(); // main FOC algorithm function

current = currentSense.getPhaseCurrents();

current_magnitude = currentSense.getDCCurrent(); // https://docs.simplefoc.com/inline_current_sense#example-code

//current_magnitude = currentSense.getFOCCurrents(); // https://docs.simplefoc.com/inline_current_sense#example-code

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬mySerial_send▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// On envoie au M5StickC-plus la vitesse en RAD/S

long now = millis();

if (now - 10 > timestamp) { // 250 ==> 4x per second

//valPOT=analogRead(PIN_POT1); // ==> PIN_POT1

//sensor_getAngle = sensor.getAngle(); // get the angle, in radians, including full rotations

valVEL = sensor.getVelocity();

//valVEL = motor.shaft_velocity;

toSEND = ("V" + String(valVEL) + "\n");

Serial1.write((char*)toSEND.c_str());

// P=VxI

//valWATTS = ((motor.voltage.d+motor.voltage.q)*current_magnitude);

valWATTS = (driver.voltage_limit * current_magnitude);

toSEND = ("C" + String(valWATTS));

Serial1.write((char*)toSEND.c_str());

toSEND = ("S" + String(sensorTYPE)); // sensorTYPE = 0 == smooth // sensorTYPE = 1 == sensor

Serial1.write((char*)toSEND.c_str());

timestamp = now;

}

// if (motor.target == 0.0f && motor.enabled == 1) motor.disable();

// if (motor.target != 0.0f && motor.enabled == 0) motor.enable();

motor.move();

command.run();

} // End loop

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬End_loop▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Can you update and try again?

Hello,

I’m testing tomorrow, the board is still at the FabLab.

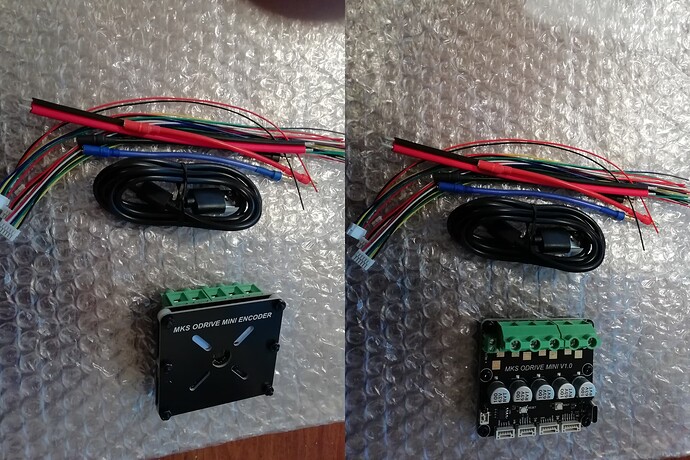

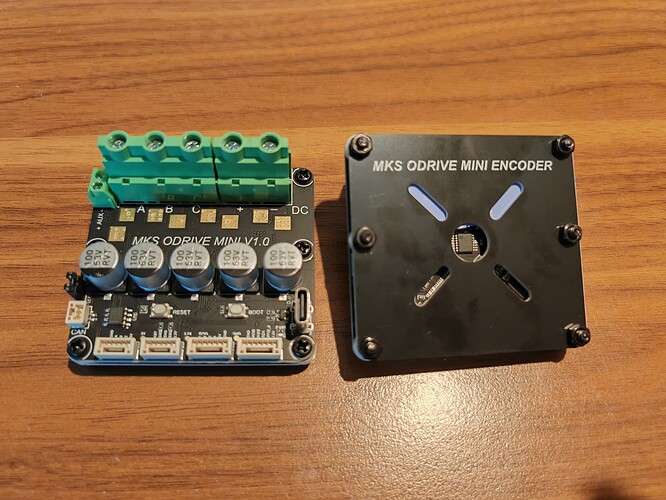

I’ve just received the card you found on Aliexpress with its encoder (really cheap).

I’ll try to test it over the weekend.

Hehe ![]()

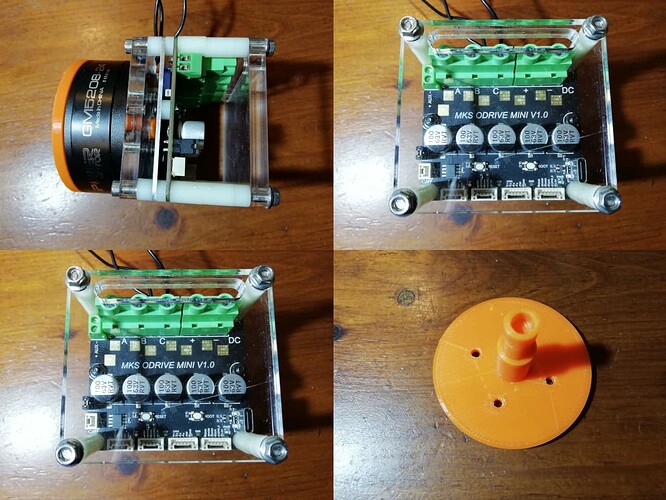

Of course we’ll share the code, I’m thinking of testing it with an iPower GM5208-24 motor I have on hand.

https://fr.aliexpress.com/item/4001296722586.html

Hihi lol Copieur !

Hihi lol Copycat!

I’ve just tested the latest dev version of SimpleFOC,

everything is fine on this version with the configuration used in this post.

Thank you for your work !

Code from my tests of Odesk 4.2 (version with scooter motor and hall effect sensor)

https://sourceforge.net/projects/openhardware-eu/files/STM32F405RGT6/

Short video

https://master.dl.sourceforge.net/project/openhardware-eu/STM32F405RGT6/STM32F405RGT6.MP4

First attempt to implement a GM5208-24 motor with the ODESC 4.2 board and an AS5047P

Tests to follow …

The map schematics are here:

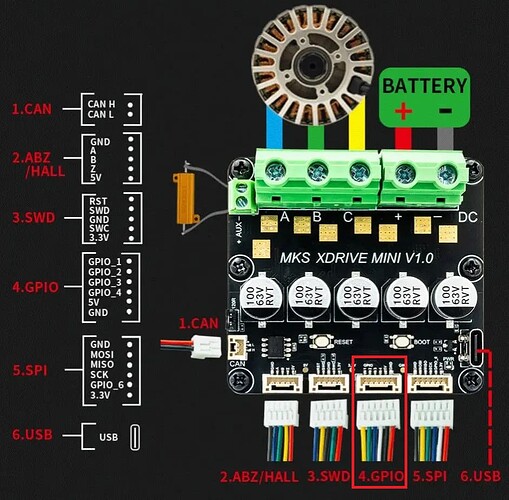

https://github.com/makerbase-motor/ODrive-MKS/blob/main/Hardware/MKS%20ODRIVE%20MINI%20V1.0%20Schematic.pdf

I still can’t understand why it was so cheap, based on the schematics it has the same STM32F405RGT6 chip, same DRV8301DCAR driver, and the same NTMFS5C628NLT1G mosfets as the XDRIVE-S but has a AS5047 encoder for about 20e less

https://www.aliexpress.com/item/1005006314725836.html

But it’s not available anymore, maybe it was a mistake

The braking resistance was missing although it’s listed

Yes, I don’t understand the price, we’ll see if it comes back, and at what price …

for the moment I’m trying to read the AS5047P, but I can’t seem to do it.

/*

SimpleFOC MKS DRIVE MINI + AS5047P

SimpleFOC_STM32F405RGT6

Odrive 3.6 ==> Odesk 4.2

https://github.com/makerbase-motor/ODrive-MKS/tree/main/Hardware

AS5047P

https://github.com/simplefoc/Arduino-FOC-drivers/tree/master/src/encoders/as5047

Makerbase-Mini contrôleur de servomoteur sans balais XDrive, haute précision, basé sur ODriLi3.6 avec AS5047P à bord

https://fr.aliexpress.com/item/1005006480243178.html

*/

#include "Arduino.h"

#include "SPI.h"

#include "SimpleFOC.h"

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬AS5047_SPI▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// magnetic sensor instance - SPI

#define CS PA15 // GPIO 7 ==> PA15 ==> SPI(AS5047)

#define SPI_MISO PC11

#define SPI_MOSI PC12

#define SPI0SCK PC10 // PC10

// MagneticSensorSPI(int cs, float _cpr, int _angle_register)

// config - SPI config

// cs - SPI chip select pin

// MagneticSensorSPI(MagneticSensorSPIConfig_s config, int cs)

//MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, CS);

//MagneticSensorSPI sensor = MagneticSensorSPI(AS5047_SPI, CS);

MagneticSensorSPI sensor = MagneticSensorSPI(CS, 14, 0x3FFF); // // alternative constructor (chipselsect, bit_resolution, angle_read_register, )

// https://github.com/simplefoc/Arduino-FOC/blob/ee2dfdeee62bc28fdee5820fb1d26a0af4dc80c9/src/sensors/MagneticSensorSPI.cpp

// https://github.com/simplefoc/Arduino-FOC/blob/master/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_spi/magnetic_sensor_spi_alternative_examples/stm32_spi_alt_example/stm32_spi_alt_example.ino

// these are valid pins (mosi, miso, sclk) for 2nd SPI bus on storm32 board (stm32f107rc)

// SPIClass SPI_2(mosi, miso, sclk);

SPIClass SPI_2(SPI_MOSI, SPI_MISO, SPI0SCK);

float Angle;

float Angle2;

float Velocity;

void setup() {

// initialise magnetic sensor hardware

sensor.clock_speed = 500000;

sensor.init(&SPI_2);

_delay(2000);

} // End setup

void loop() {

sensor.update();

Angle = sensor.getAngle();

Angle2 = sensor.getSensorAngle();

Velocity = sensor.getVelocity();

Serial.print(Angle);

Serial.print("\t");

Serial.println(Velocity);

} // End loop

Someone on discord who was in contact with the vendor remarked that they were just out of stock for now and that the shop will add more on Feb 20. (supposedly)

@VIPQualityPost prefect ![]()

AS5047P is now working properly.

/*

SimpleFOC MKS DRIVE MINI + AS5047P

SimpleFOC_STM32F405RGT6

Odrive 3.6 ==> Odesk 4.2

https://github.com/makerbase-motor/ODrive-MKS/tree/main/Hardware

AS5047P

https://github.com/simplefoc/Arduino-FOC-drivers/tree/master/src/encoders/as5047

Makerbase-Mini contrôleur de servomoteur sans balais XDrive, haute précision, basé sur ODriLi3.6 avec AS5047P à bord

https://fr.aliexpress.com/item/1005006480243178.html

*/

#include "Arduino.h"

#include "SPI.h"

#include "SimpleFOC.h"

//▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬AS5047_SPI▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

// magnetic sensor instance - SPI

#define CS PA15 // PA15 // GPIO 7 ==> PA15 ==> SPI(AS5047)

#define SPI_MISO PC11 //

#define SPI_MOSI PC12 //

#define SPI0SCK PC10 // PC10

/*

MagneticSensorSPIConfig_s AS5047P_SPI = {

.spi_mode = SPI_MODE1,

.clock_speed = 1000000,

.bit_resolution = 14,

.angle_register = 0x3FFF,

.data_start_bit = 13,

.command_rw_bit = 14,

.command_parity_bit = 15

};

MagneticSensorSPI sensor(AS5047P_SPI, CS);

*/

// MagneticSensorSPI(int cs, float _cpr, int _angle_register)

// config - SPI config

// cs - SPI chip select pin

// MagneticSensorSPI(MagneticSensorSPIConfig_s config, int cs)

MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, CS);

//MagneticSensorSPI sensor = MagneticSensorSPI(AS5047_SPI, CS);

//MagneticSensorSPI sensor = MagneticSensorSPI(CS, 14, 0x3FFF); // // alternative constructor (chipselsect, bit_resolution, angle_read_register, )

// https://github.com/simplefoc/Arduino-FOC/blob/ee2dfdeee62bc28fdee5820fb1d26a0af4dc80c9/src/sensors/MagneticSensorSPI.cpp

// https://github.com/simplefoc/Arduino-FOC/blob/master/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_spi/magnetic_sensor_spi_alternative_examples/stm32_spi_alt_example/stm32_spi_alt_example.ino

// these are valid pins (mosi, miso, sclk) for 2nd SPI bus on storm32 board (stm32f107rc)

// SPIClass SPI_2(mosi, miso, sclk);

SPIClass SPI_2(SPI_MOSI, SPI_MISO, SPI0SCK);

float Angle;

float Velocity;

void setup() {

// initialise magnetic sensor hardware

//sensor.clock_speed = 500000;

sensor.init(&SPI_2);

_delay(2000);

} // End setup

void loop() {

sensor.update();

// Read variables on STMViewer and St-Link V2

Angle = sensor.getAngle()*1.0;

Velocity = sensor.getVelocity();

} // End loop

The card works great! ![]()

I’ve just tested it in foc_current & velocity mode with success.

All that’s left is to fine-tune the P.i.D.

And a good STM32 coder will have to add ADC management for read temperature and also to read a potentiometer with analogRead()

I’m sharing my current code with you.

https://sourceforge.net/projects/openhardware-eu/files/SimpleFOC_MKS_DRIVE_MINI/

I played around with the board yesterday, for some reason in closed loop/voltage mode with hall sensors it didn’t work well.

I need to figure out why this weekend.