Changelog:

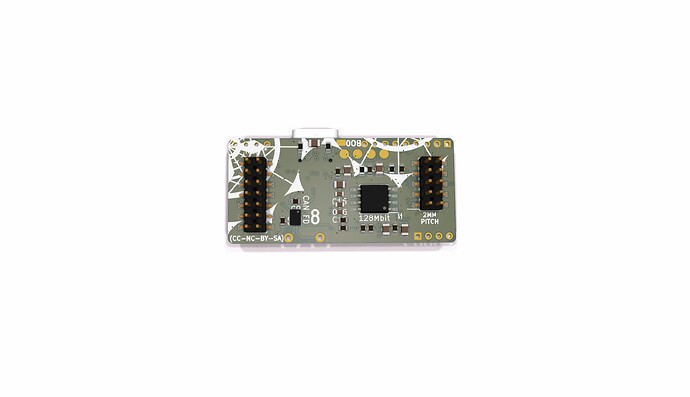

The low_voltage QSPI pin scenario is to dodgy IMO. So I have chosen a 128Mbit (16MB) IC with a 3.6v rating, instead of the 2v rated BGA.

532MHz equivalent Dual/Quad SPI

If used for some science data acquisition experiment, maybe batterie powered, It will be a nice feature to have 16MB of external memory for logging. Maybe I should focus on the battery pin. Edit: The battery power pin is only for the backup domain, which has limited functionality. If powering the MCU for logging in the field, a USB battery should be used.

Comparing USB bandwidth/datarate with a QSPI memory for logging motor data is dificult. Especially if the USB interface is based on Serial (single char transfer) like the SimpleFocStudio. When doing single char transfers, the USB protocol overhead becomes a bottleneck.

In theory, the QSPI FLASH memory, can be divided into eg. 2MB sample segments, which enables testing a motor at eg. different torque settings or similar. Efter the test_run the acquired data can be compared.