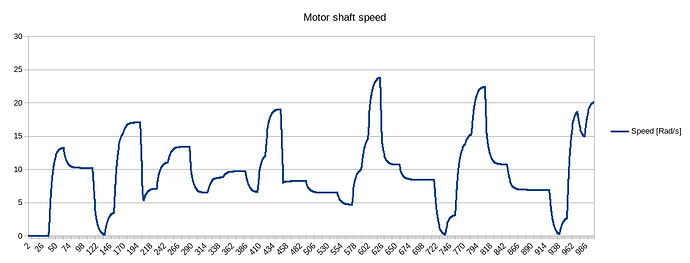

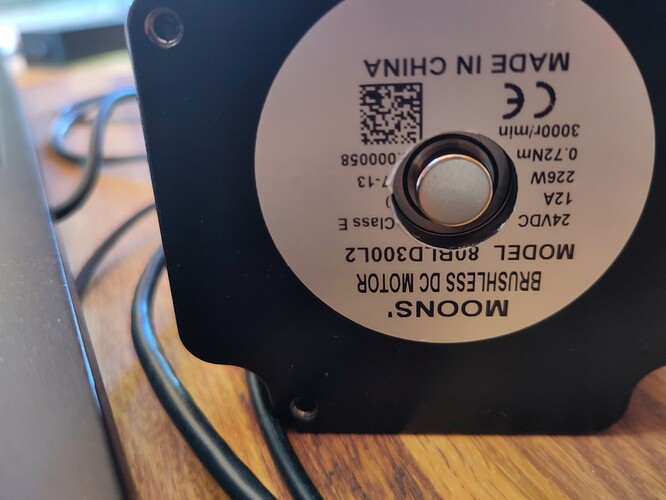

The max speed is 540 stitches/minut (info is provided in video). The gearing to motor is about 1:20 and make use of a small speed reducer. I already know, that a brushed DC motor will be able to perform better than seen here with a wider speed range, but the cost of components are larger as well.

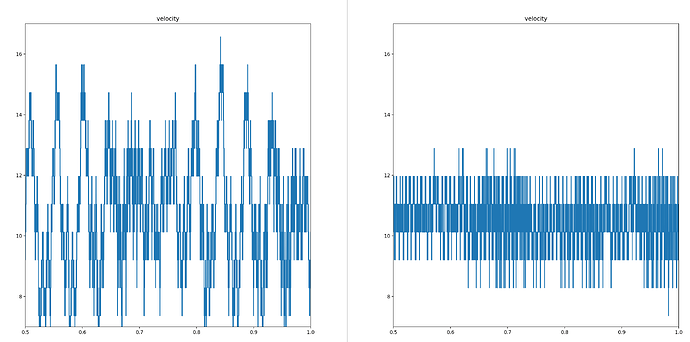

I agree.  Some more work on that is needed.

Some more work on that is needed.

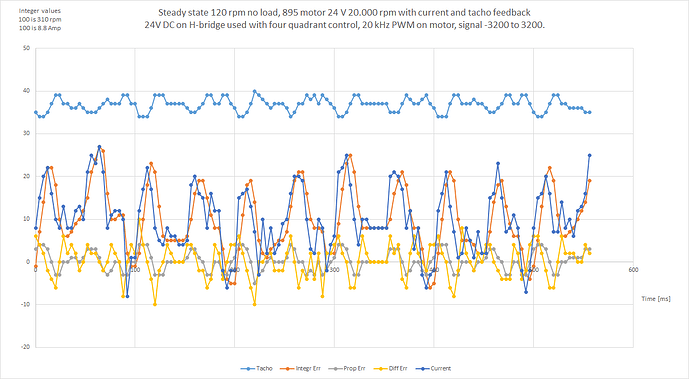

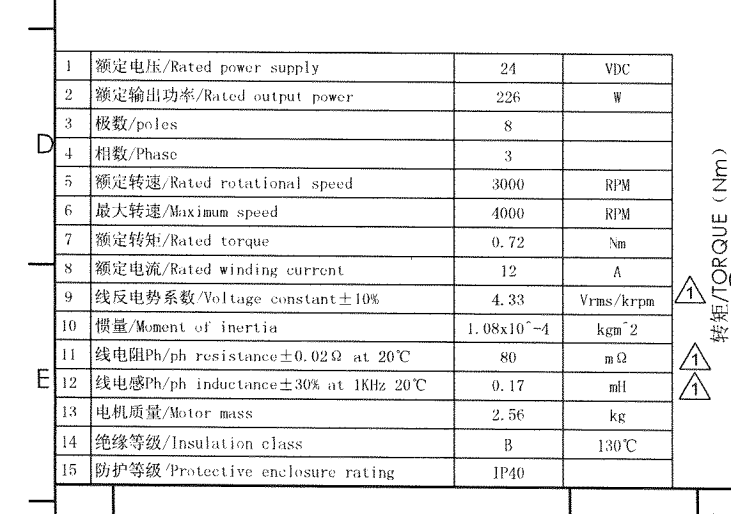

It is a very good question. I tried to have the motor run slow with a current of 13 Amp for 5 minutes, and immediately after that I put in a K-type thermo coupler into the windings to get an idea of the temperature, and it reached 95 C. I think the mean cobber resistance at 25 C is 0.12 ohm, so the resistive loses at 95 C would be about 26 W. It is my plan to estimate motor temperature in software, by use of the measured motor current.

I use an H-bridge called IBT_2, and it got serious problems due to switching losses, that becomes far bigger than the losses due to on resistance of the power mosfets. Therefore, some of the programable ESCs on market may very well perform better if they are used with a brushed DC motor. Therefore some ESC with a number of extra input/output pins could be an advantage.

Thank you for this link, that got a lot of information. It will take some time to read and understand. But from a short reading it looks interesting.

I have been looking for data, that might give an idea of how responsive such drives are. In the mean time I think I found it in two other links:

This video show a measured step response with a transition time of about 100 ms, and it is based on measurement on sound:

https://www.youtube.com/watch?v=XjhY2tyhYZ8

This other video is only 4 weeks old, and compare the step response on five different ESCs for drones performed on the same motor and propeller:

To me all five ESCs perform almost equally fast, and differences are minor. The time for the speed change 10% to 50% throttle is about 50 ms. I think it very fast, and it show me that there is nothing special about these kind of motors and drives, that makes them less responsive than a brushed DC motor. Perhaps brushed coreless DC motors are faster, but it is another matter, and faster controls than shown here is not needed at all for sewing machines.

According to this video, the use of FOC in ESCs for drones is new, and one of the five ESCs tested are this new ESC on market. It might perform a bit better, but no significant change, when I look the test data. Without knowing much about this, I should think that breaking of the motor could be done faster, if you want to make the ESC do this more actively. It seems that short circuit of terminals are used as the way of breaking. There is no drought good reasons for that.