The ones I’m doing are 1lb and 3lb weight class (ant and beetle). For those, I tend to run higher voltage (4S+) which is a bit unusual, and I’ve previously been using (mis-using) 12V/1k RPM N20 motors (2-4 for 1lb, and 4-6 for a 3lb robot). They draw about 1A each short circuit.

Lately I’ve been playing with moving to brushless hub motors, but unfortunately that’s not really a well serviced area in the hobby BLDC market. Ideally I’d want 4-8 ohm resistance motors that are most of the way towards a typical 12ohm small 3-4S gimbal motor, but with slightly beefier windings and slightly higher kV rating.

Unfortunately those don’t exist

The problem I’ve got is that cheap sensorless hobby ESCs tend to have startup/cogging issues around their bottom 10-20% of the throttle. For a differential drive robot trying to steer precisely (for example rotate on the spot to face the opponent), that’s really annoying. A human operator can overcome it (expand the deadband on their stucks, and close the loop by eye), but one of my bots has a PID auto-aim system that tries to face the opponent. This is already needlessly complex, but since I’m having a lot of fun I’m doubling down and trying to fix the control problem (or at least improve it).

The other options are to have a nearby PC run SLAM to close the loop (which is fine by the rules, but IMO kind of against the spirit since the PC’s safety isn’t “in the ring” like the other bot), or to use something like mouse optical flow sensors (a pair of them by the sides) to track actual motion, but those both have the drawback of not being part of the motor control loop.

There’s a VESC project by a UK team that’s close to what I want, but it’s $80/unit (which is being sold nearly at cost), and I’m typically looking to spend $80-200 on 1lb, and maybe twice that on 3lb bots.

So here I am

The motor I’m using on my latest ant weight is a $5 265kV 4S rated 12.5 ohm 19g 1807 can gimbal motor that’s a little heavy but otherwise pretty much perfect for a direct drive, or single stage reduction 2-4WD ant or beetleweight. I’m probably not going to use this board for my next competition, but I’m gearing up to have it in the wings for the following one (maybe this coming winter).

One of the “neat” things about combat robots is that a lot of the voltage ratings, MTBF numbers, etc. become a lot more flexible. It’s got to last 1 or more 3 minute bouts, and after a few of those if it still works, that’s a huge plus. I’m a lot less worried about overheating, and as a result can get away with running motors 10-50% over their rated voltage, trace width heat dissipation can be +80C, and all sorts of silly things that are typically bad ideas

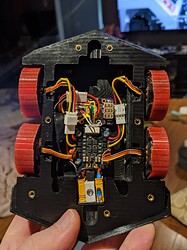

Also, for photos, here’s the 1lb X+Y radially symmetrical, semi-autonomous wedge bot I’m working on:

The current version uses:

- 4x D1807 unbranded hub motors

- Custom polyurethane wheels (Shore A 35)

- 1" HDPE billet frame (black)

- 3mm HDPE top/bottom armor (white)

- 1.2mm hardened 4130 front/back wedges

- 4S 350mAh LiPoHV batteries (in a tray on the bottom opposite the electronics)

- Custom NRF52832 based control board

- Custom SAMD21 based sensor processing board

- 4in1 BLHeliS drone ESC

- 4x VL53L5 3d ToF lidars (2 front, 2 back)

![]()