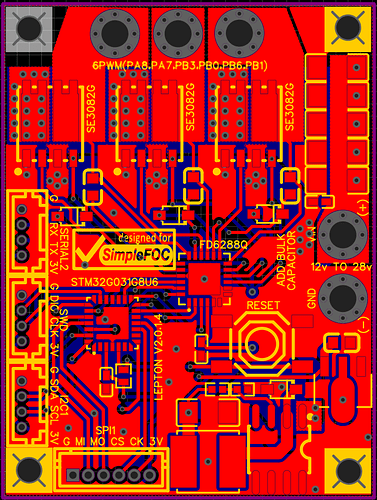

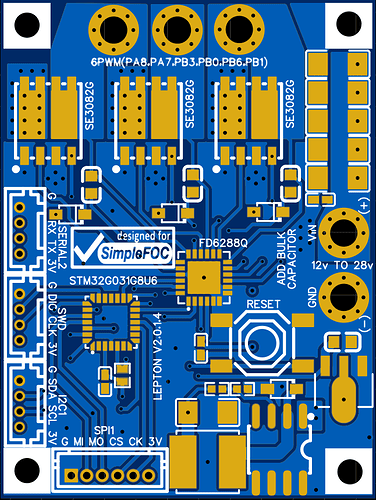

I’m opening a new thread, since the old one didn’t work out. This is a complete rework of my idea of an ultra-cheap SimpleFOC board. I tested it, it’s working. There is no current sensing, because at that low power you won’t really benefit from current sensing much.

Features:

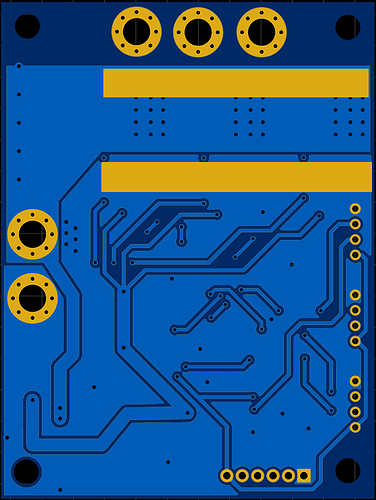

30mm X 40mm

2-layer (!!!)

30V / 80A (170A peak) H-bridge integrated MOSFETs.

Fortior Driver

STM32G031 / 64MHz MCU

SPI, I2C, Serial and SDW pinouts

12V Buck

3V LDO

Less that $10 to manufacture including SMD and components !

I will post the schematics. This is a reference design, for those that are learning how to make SimpleFOC full-stack driver boards.

Please be extremely careful. This board is only for educational purposes. The 1oz copper will not carry more than 10A max if you are lucky, even though the MOSFETs are rated at 80A continuous. If you need more current you need to go for 2 oz copper, and 4-layer board, which means you will have to redesign the board by inserting extra copper layers, this will increase the current carrying capability to about 40A continuous (80A max pulse for a few milli-seconds) with good heatsinks and proper cooling. Also you MUST add an external 50V / 1000uF minimum bulk capacitor.

Enjoy and please ask questions.

Cheers,

Valentine