No success with the 2208 motor yet. As with the small motor the sensor gap was too large to get reliable readings, so I ground the rotor lip flush with the magnets and reduced the gap to 0.5mm. Spins perfectly open loop, but closed loop just buzzes in place. Odd since it did spin poorly before. Maybe the missed sensor changes were what allowed it to move forward. I’ll keep fiddling with it.

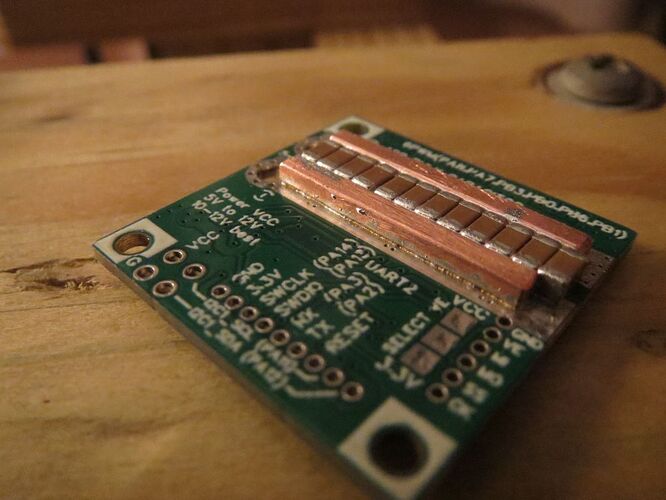

In more exciting news, I was at Micro Center the other day and spotted a syringe of tin-bismuth solder paste. I decided to give it a try for soldering all the copper bits, and this is the result.

I’d say next time I should be a bit more liberal with the paste, but nonetheless a satisfactory result for a first try (after a small test on scrap PCB).

I hammered the copper wire into nearly square cross section this time so it’s the same height as the capacitors. This way the board could lay flat on its back while melting the solder on both sides at once. It worked, but making the bars taller results in them not being quite wide enough to cover all the vias. The top bar maybe also should be a bit longer to reach that third row of vias that comes up beside the MOSFET. The bottom one could actually be a bit shorter. The last set of vias it needs to reach can be seen right above the silkscreen “VCC”.

Applying paste to all the capacitors took a good while, so I’m not sure this is actually superior to how I did it before with a soldering gun. Much better for the tiny copper bits on the top side though. And it does make positioning the bars more precise and relaxing. Maybe next time I’ll just slop more paste on the bars and smush the capacitors into it rather than carefully applying it to each of them. Or solder one bar this way, and then do the capacitors and other bar with the gun (it’s easy once you have one bar tacked in place so you can push up against it, plus that would allow using wide/thin bars like before). Or ditch the ceramics and use more electrolytics.

To melt the solder, I placed it on a 2x2x0.5 inch block of aluminum I had lying around, put that on the stove, and lit it up. Low flame for a minute or two until the solder goes shiny, give it a few more seconds, and turn it off. Note the spare capacitor peeking under the edge which is being used as a spacer to make sure the board lays flat on the copper bars and other capacitors. Pay no attention to the mess of food crumbs in the burner tray ![]()