Hi.. my question and problem has nothing to do with FOC, actually, but If someone can point me how to find a solution it would be great…

I need a way to connect/disconnect a 3 phase BLDC motor from the A, B and C output terminals of a BLDC Sensorless (BACK_EMF) driver. I don’t have access to mod the driver, so the only access point I’ve got it’s the A, B and C terminals that connect to the motor. I’ll add an extra MCU to control the “connecting” or “disconnecting” the motor from the driver.

The reason I want to do this is that I want to have two equal motors, connected to the same one driver, but only one motor will be on at a time. When using one, the other will be “disconnected”, and vice-versa.

My motors runs at 36VDC, at 1A, and at peak, at 3A the driver protects it and stops the motor. The frequency the driver outtputs, in pwm at each phase is variable. At low speeds it’s slower, but it’s no more than 30KHz at max speed.

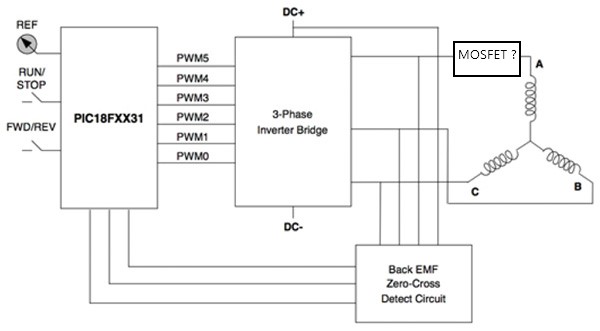

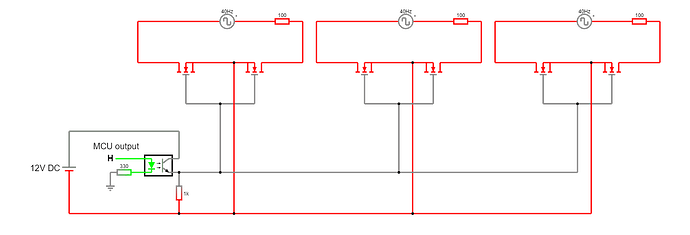

I was thinking that I needed three mosfets, one for each phase, connected between each output of the driver (A,B or C) to each winding of the motor. And f I turned off the three mosfets the motor would be disconnected, and if It I turned on the three mosfets the motor would be connected to the driver and allowed to work, like in the picture below:

The commutation for the sensorless back-EMF BLDC is a 6 step trapezoidal sequence. So the current moves both ways in the three windings, correct?

So simple mosfets would allow current in one way only, not the other direction, right?

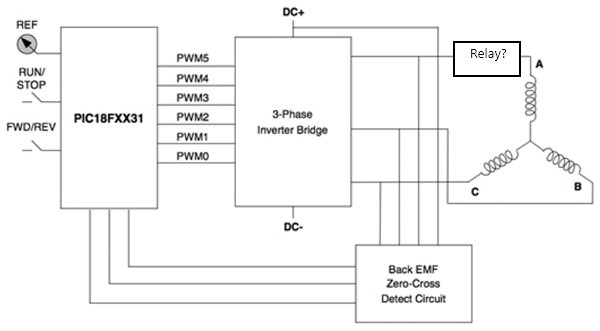

So I could use three ordinary relays, each on each phase right? But I wanted to avoid relays. But if a relay was used, would this fast switching back and forth of the current cause any trouble on the commutation sequence? Noise? Some other problems?

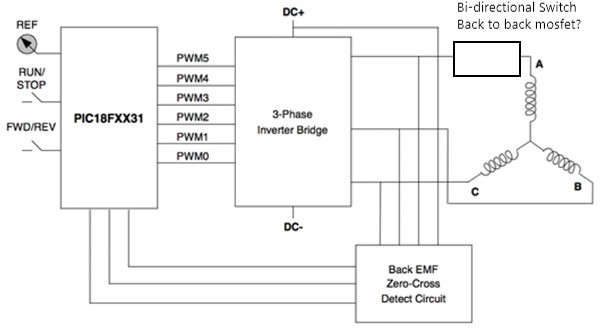

Then I was researching, and it seems that I need some kind of bidirectional mosfet switch. And It could be done with P or N mosfets. It seems that with N mosfet it would be better in terms of having a low RdsON, less heat, smaller size.

I was reading about this bi-directional switch here: https://www.homemade-circuits.com/bidirectional-switch/

Something like in the picture below:

So I would need one circuit like this above for each output of the driver, for each motor

The marked in blue A would be one of the outputs of the driver and B would be the corresponding winding of the motor.

So… would I need three of these set-ups for each motor? Would it work? When a motor is in the “connected state”, would the fast back-and forth current switching of the 6 step commutation work as there were a direct connection between the driver and the motor’s windings? Would the motor work normally?

Or.. would there be a better and simpler solution?

Thanks!

Rodrigo