Shortage expected to continue through 2023.

Hey, do you read Chinese, or did google translate help you out? Just interested…

I have translators working for me (seriously). However, google translate for basic stuff in Chinese is really good, I was told.

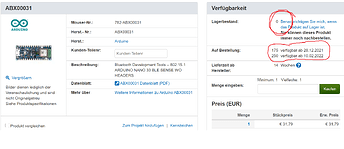

I’m looking for an “Arduino Nano BLE Sense”, but the price for the last pieces is rocketing! ![]()

Anyone has a spare one?

Otherwise I will go for the Nano BLE and get the sensors separately…

Thanks.

Out of stock everywhere.

Ona more positive note, the STM32F103 prices are falling, it went from $12 to $7 in a couple months.

It’s just a matter of waiting that out. As Sean Connery says, “If you sit by the river long enough, you will see the body of your enemy floating by.”

Hey @quentin ,

I have a BLE Sense (with headers) that I could spare, realistically I won’t need it urgently any time soon, I can test simpleFOC on the BLE (no sense) just as well.

Mouser has them coming in 28.12: https://www.mouser.at/ProductDetail/Arduino/ABX00031?qs=PzGy0jfpSMu0EzmBD9iegg%3D%3D

I’ll just order a new one there.

DM me your address…

Richard

Interesting. This is what I see from US:

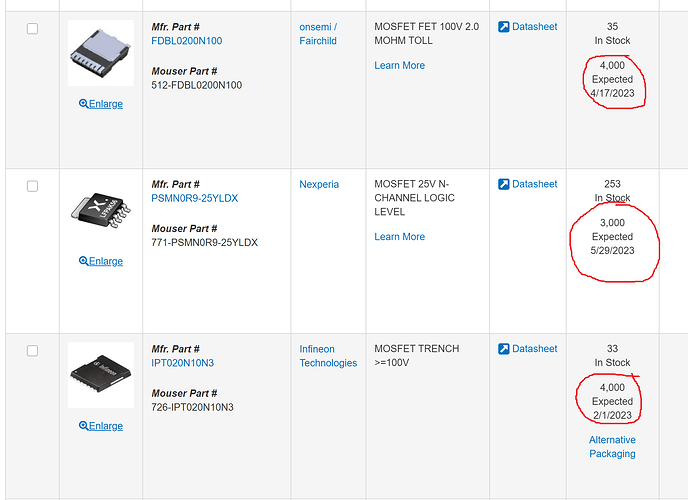

Will they be able to honor the dates? All other places keep pushing the dates into 2q and 3q 2022

Who knows, but really, if @quentin can use it for something right now then its better than it sitting in my “MCU collection” ![]()

True. I have 33 but no the sense one (ARDUINO NANO 33 IOT), too bad. However that one is in stock everywhere anyways. Oh well.

@Valentine, that’s exactly what I thought. I found a few “optimistic” providers, but I was afraid they cannot make it.

@runger , please let me reiterate the thanks from my PM, that was very kind of you. To others: out of impatience and fear that other Arduinos would become unavailable, I had already ordered a Nano BLE (no Sense) and an external sensor breaking board.

The current war in Europe is further pushing the semiconductor shortage out to 2024. Ukraine is (was) the world’s largest (between 50% to 70%) exporter of noble gases (neon, krypton and xenon) which are used in semiconductor manufacturing.

This is definitely getting worse.

Fascinating case study in economics. It’s called the Giffen Effect, Giffen Paradox or Giffen Behavior. The Giffen Effect is an economic supply/demand situation where an income effect, due to a price rise, outweighs the impact of a substitution effect upon the quantity demanded of the good.

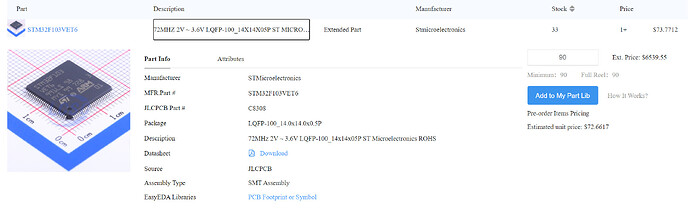

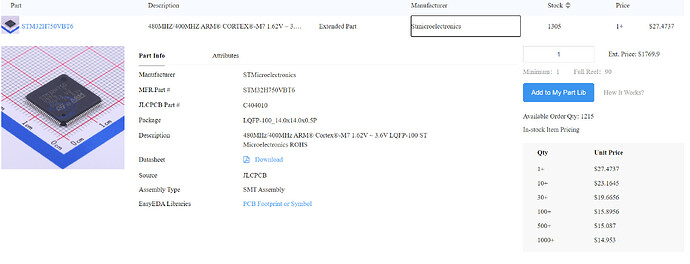

Below is the end result. Examine the prices of two common MCUs. One is STM32F103VET6, an entry level, generic MCU. The other is STM32H750VBT6, a high end, high performance MCU. Both are in stock, and available. As you can see, the price of the basic STM32F103VET6 is nearly three times the price of the high performance STM32H750VBT6.

Even lower end STM32F103 (less memory/lower pin count) are more expensive than the massively better H750.

Such scenarios occur only in cases of very dramatic supply/demand and income distortions.

I’m not sure what that means for the broader market, or future of silicon manufacturing, but one thing is sure, the landscape is changing quite seriously.

The really interesting question is why ST-Micro can’t get any MCUs produced? Or are they producing some, but only for certain customers and not the open market?

US Made MCUs (TI, NXP for example) are available, as are Chinese made ones… so why not the ST-Micro ones?

The way I read it, the chips that are available are old or surplus stock they’re digging out of some corners, and the price is more or less random… if you check the prices of STM MCUs on AliExpress and eBay, its just usury… $100 for a MCU?? You can get a GHz multi-core processor for that money!

Global supply chain disruptions. Starting in the 80s, and then in late 90s/early 2000s, there was a full transition to “just in time” manufacturing and distribution. Coupled with globalization and outsourcing of the supply chains and actual manufacturing of the end product, the end effect was that even small disruptions in the individual supply chains would produce a ripple effect from beginning to the end of the supply chain. The first real warning sign which the general public noticed was the 2011 floods in Thailand. For example, Western Digital, a leading US supplier, had two factories north of the capital Bangkok which were fully under water. “We can’t make any hard drives there because the whole supply chain has been broken and we don’t have enough parts,” explained company spokesman Daniel Mauerhofer. “It’s a problem for the whole HDD sector, not only for us.”

Nobody learned from these mistakes, it appeared.

Fast forward to 2020, when COVID19 hit. The silicon manufacturers curtailed their orders, anticipating lower demand for silicon (here I mean any semiconductors, not just raw silicon). The WFH/SAH company policies however perversely increased the need for silicon, in the forms of computers, mobile/handheld devices and also the jump in crypto-mining due to the unfortunate coincidental jump in speculative value of cryptocurrencies (demand for high-end videocards used for mining).

The result was that suddenly the global manufacturing/supply chain was pushed to increase manufacturing, on the back of curtailed orders of inputs, as well as transportation breakdown due to the pandemic. Then price of oil, which originally dropped to negative (-$40/barrel), went up dramatically even before the war in Ukraine, and everything went up accordingly. Inflation also went up due to the global shortages which propagated to all sectors of the industry, not just silicon manufacturing. COVID didn’t go away, and China implemented a zero COVID tolerance policy, whereby they would literally shut down entire multi-million population cities playing key roles in the silicon supply chain, especially east around Shanghai and down south around Guangzhou (north of Hong-Kong). By the way, JLCPCB, the largest small-batch PCB manufacturer in the world, is located Shenzhen, right next to Hong-Kong.

Enter the modern electric car. Demand for silicon for an electric car is quite massive, due to cars using mainly silicon instead of ICE. Even the older hybrid cars, or fully ICE cars started to use silicon on a scale never seen before.

The wheels of the proverbial silicon bus literally came off.

The answer why ST-Micro can’t get any MCUs produced is that they do produce plenty of MCUs, just not on the scale previously done, and the smaller quantities therefore, typical supply/demand, went up from $2 for an F103 to $30. When you have a $50000 car sitting on the manufacturing floor, waiting for a $30 dollar chip, which used to be $2, any supply manager would pay to move it. You cannot redesign the PCB and rewrite the embedded code, which has passed all tests and safety and security certification, that’s out of question. So you close your eyes, put in an order for 10000 chips and pass on the cost to the consumer. Hence, the Giffen goods effect.

And now for the 1-2 punch. Ukraine was the largest exporter of Xenon, Neon and Krypton, the noble gases exclusively used in silicon manufacturing. Then the whole world embargoed all the stuff coming out of Russia, too, which was exporting the rest of the raw materials, rare earth used in magnets, whatever, punishing them for whatever they currently do in Ukraine. Oil went up to north of $110. This is going to get worse before it gets better (if ever any time soon).

Because the ST Micro are the best in class. And most widely used. And used to be the cheapest. Sir Robert Giffen is laughing at us.

Yes but BMW, Mercedes, FORD, GM, Tesla, and the rest, each have to pay a separate team of ten engineers that make $250,000/year in salary to develop and test and certify a new PCB. The cost of each of these engineers is usually 1:2 so each engineer internally costs about $500,000/year for a company like Tesla (cost of salary, office, HR, taxes, insurance, benefits, doing their laundry, feeding them top of the line sushi for lunch and giving them 100,000 bonus at the end of the year, etc.) Cheaper to pay $30 instead of $2 per scarce MCU. STM is laughing all the way to the bank right now.

Oops.

Valentine

PS One fairly predictable outcome I’ve been considering. I keep seeing hobbyists on this board looking for the mythical $10 BLDC driver board that does everything, and then some. With the current situation, even after the inventories return, which will take longer than a year, the price of components will be so expensive that it won’t be realistic to expect anything near the levels of 2019. More like multiple times. The reason is that once the global supply chains readjust, since it takes so long, the cost will stay high because the price points would have been already set so high by the deep pocket players that the manufacturers and distributors won’t back down from these profit levels. Which for the retail consumer means that the inventories will return but at a lot higher price point. I already see some high end MOSFETs which used to cost $1 are coming back at $5 to $10 per MOSFET. Even the cheap Chinese knockoffs are going up significantly in price.

I could be wrong on this, but so far it’s going in that direction.

So it’s a win for producers and the big pockets. Big pockets don’t care about a price increase, they just push the bill to the customers. What they do care about is not having their business disrupted. Like if some maker community where about to empower the peoples.

Looking forward to the supposedly upcoming teensy dual core 1Ghz M7 + 240 Mhz M4. Who knows when and what the price tag will be. Looking at the Portenta H7 price tag, I will say it has a limited potential for disruption.

Just how cynical big pockets is, is hard to tell. Would they deliberately release a virus to disrupt the entire economy. No one knows, there is no smoking gun, although it was well established knowledge, the disruptive potential of the bat virus. The intelligence community was well aware about the research going on in Wuhan. If someone wanted to release it, that would be the optimal location.

We are amidst a great transition. Our planet, mother earth is catching a fever, so we must transition in order to heal her. If we look at it from a timely perspective, seeing the kind of development our kind has mustered through the ages, one could see it as a transformation. The potential is liberating. Technology is and should be liberating. This shortage wont last long. Freedom for the peoples of all the nations will be victorious

And so the harvest of carbon became profitable ![]() @runger Is this for real, I see a lot of talk around 2014, seems strange the lack of available information not to mention products, testing ?

@runger Is this for real, I see a lot of talk around 2014, seems strange the lack of available information not to mention products, testing ?

Currently, PJP Eye LTD. continues development of Organic Dual Carbon Battery and completed proof of concept of the battery as laminated cells. PJP Eye has mass produced Organic Single Carbon Battery based on Organic Dual Carbon Technology in 2017. It has been integrated into various applications from personal mobilities, drones to storages. PJP Eye LTD. plans to mass produce and start commercialization of Organic Dual Carbon Battery which brand name is “Cambrian Dual ™️” by 2023 to integrated them into EVs and electric airplanes.

Source: Dual carbon battery - Wikipedia

Eyeballs

https://pjpeye.tokyo/en/

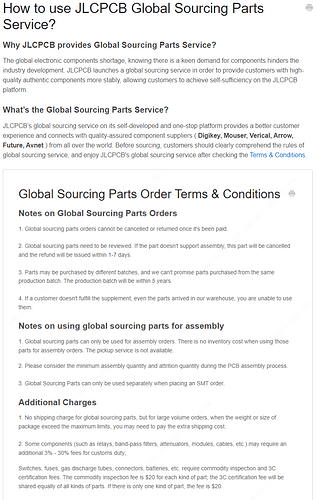

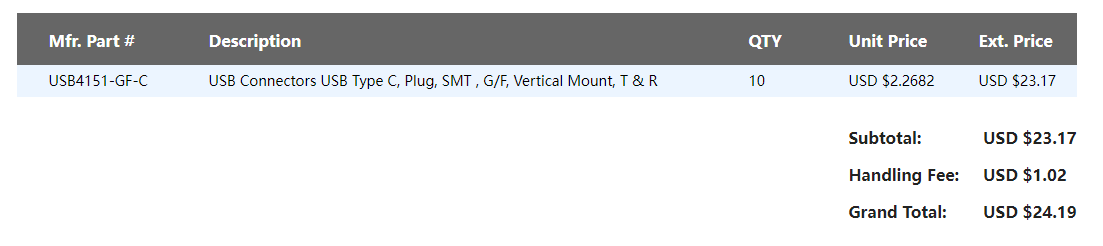

True. However, this is the latest from JLC, which may help alleviate the tight supply. Before that JLC was only partnering with LCSC. Now they are cutting a sourcing agreement with all global suppliers, which is a really big deal. Just happened over the weekend. What makes this a big deal is that you do not pay for shipping of the parts from the supplier to JLC. You may pay for customs duty depending on the supplier region. Also if you do that you can shop for the cheapest parts, before you were locked in by LCSC process only.

I’m currently checking, the feature is still rather primitive and the MOQ is mostly geared towards large batch manufacturers, however, I already see certain parts that are available to create rather decent boards, such as

STSPIN32F0602

I have tested the “JLC global suppliers” at the introduction of the service, and very happy of the results.

JLCPCB Invoice:

Mouser:

1 $2.15

10 $18.00

Resolved in less than 2 weeks, Just a little difference on reduction by 10 pieces. But the components are included at 0$ on the final SMT assembly invoice.

I would be very excited to see you using the “three-phase controller with MCU” solution from STMicroelectronics.

Probably the most advanced solution in BLDC controllers.

Note, the current availability of a variant of the L6234:

- DRV8300NIPWR

- LF2136BTR

The “Trinamic Motion Control TMC4671+TMC6100” circuits (simplefoc hacking?) seem to be announced for the end of August 2022

Kind regards everyone ![]()