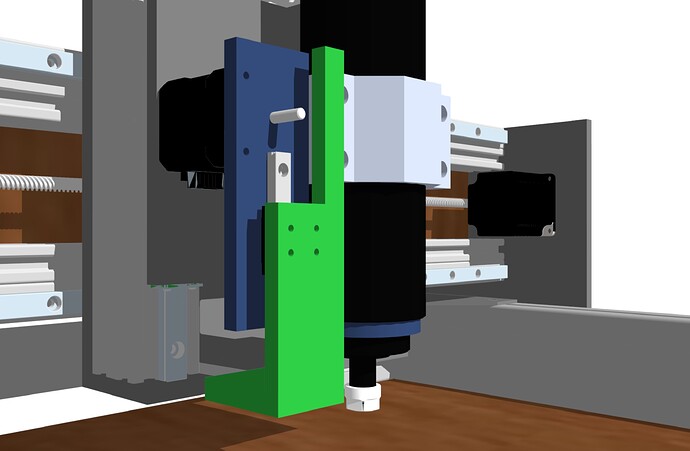

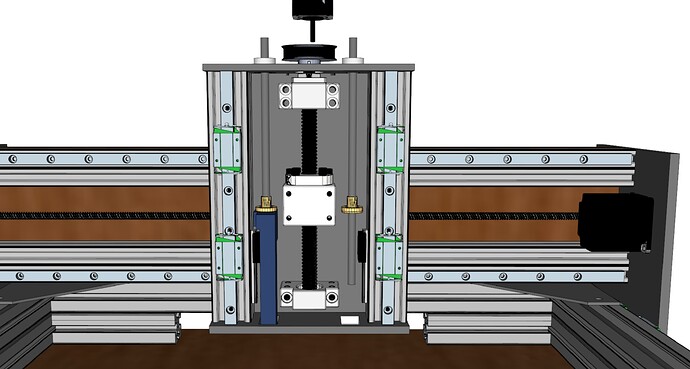

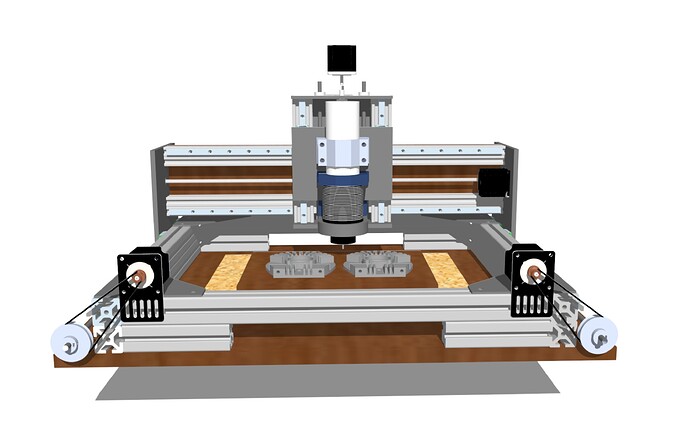

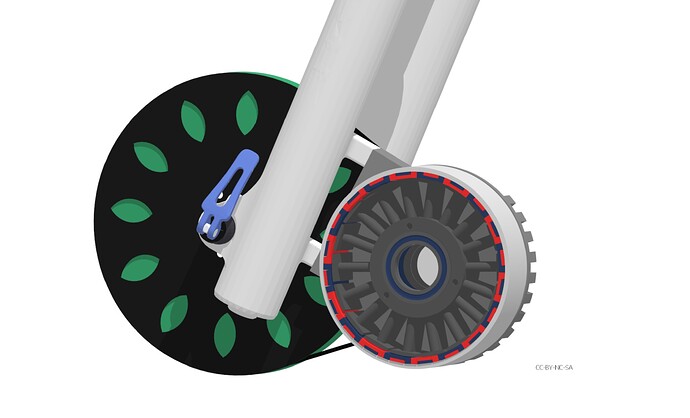

I rather focus on a system for chip extraction. With a Nema17 and a pinion gear, I believe it will optimize the whole vacuum story, if the vacuum nozzle/ring can move in the Z axis independently of the spindle. You could then make a much tighter fit around the tool without worrying about the broom hairs getting cut. The advantage of doing a independently controlled vac is the possibility to do a vacuum sweep where you plunge the bristles. That would involve closing the hole for the tool/spindle. or maybe it is stuck to the spindle, but the wall´s of the vac shoe can move, thereby allowing pressure on the bristles, to get in to those deep pockets. Maybe it is actually a advantage to have the vac shoe hovering over the work peace in some scenarios, where you don’t want the bristles limiting airflow. I guess a cloth will not interfere with the tool if used as a flexible vac membrane.

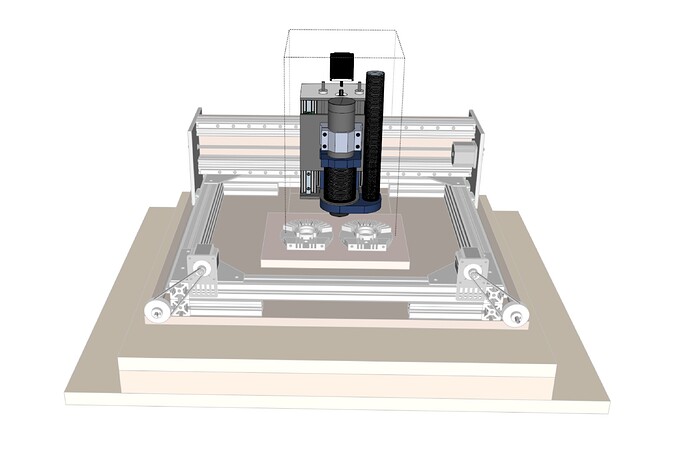

Using this flexible hose. When compressed it should make room for changing tools and when extended it should move a few centimeters. It should have a detachable vac head/whisks.

Flexible hose N1 (Ø 60mm) - Flexslange N1 - Starracing Motorsport

Here is a crude example.

Actually, why not use some of all that space in the pillar: I believe we only need bearing in to top side, since the lead screw for the VAC is attached to that small linear rail, it can only go up and down.

The flexible air hose has to be fitted with the correct length for the length of the tool. Flexible hose can become 3 times its compressed length. If cutting contour, and you have the brush plunged like half the depth, that would create a smaller diameter airgap and thereby better air pressure to remove the chips. Of course one length should work within a range of a few centimeters.

In the end the machine has to be setup for what ever surface you have and the size of your work_peace.