Hello everyone,

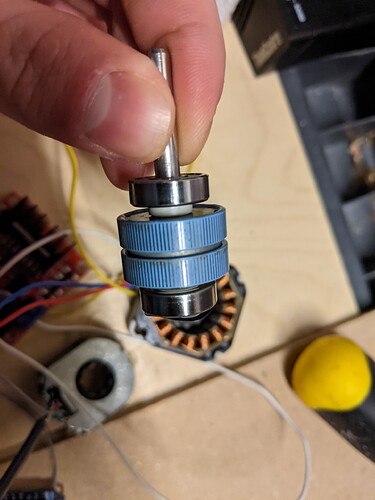

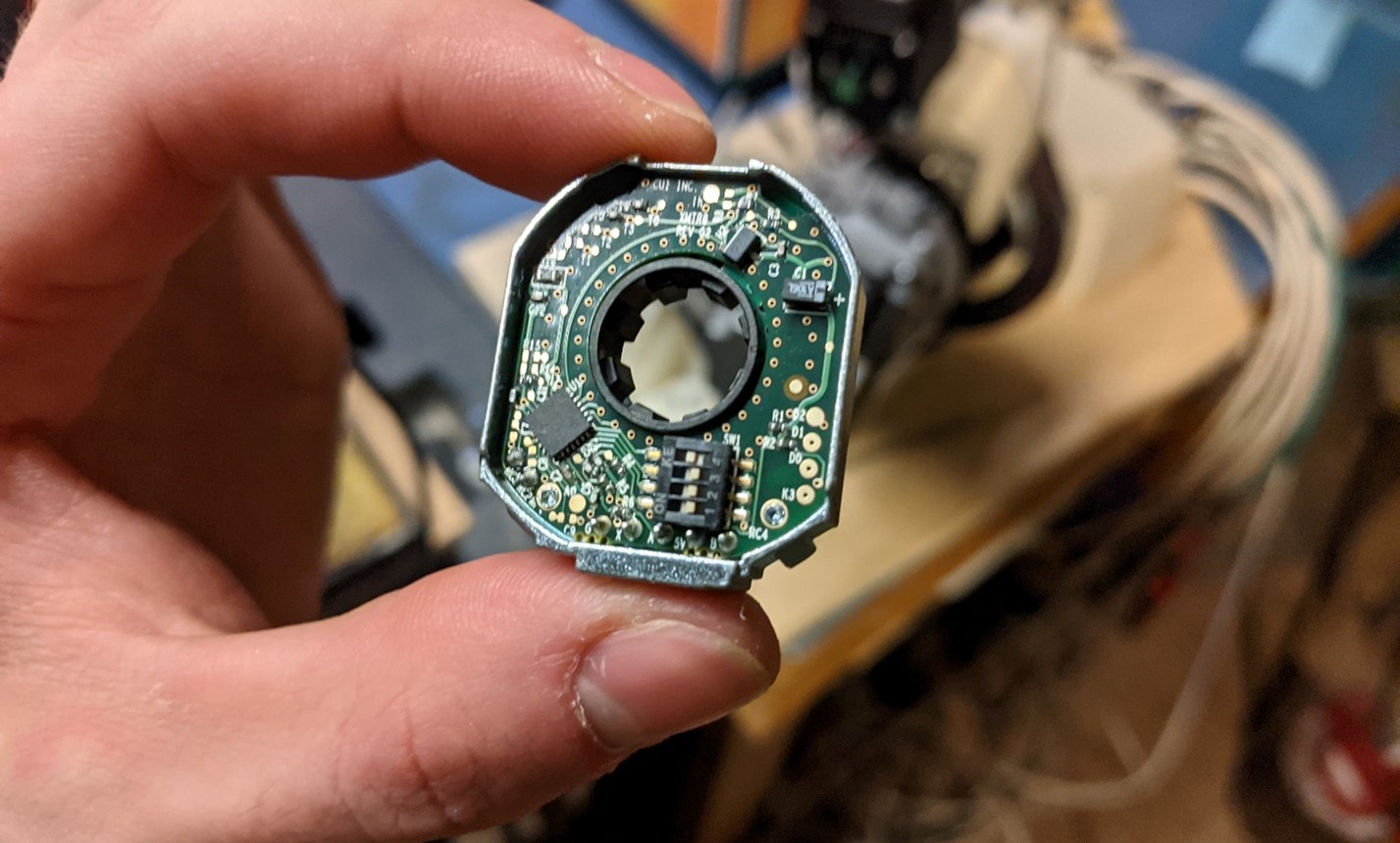

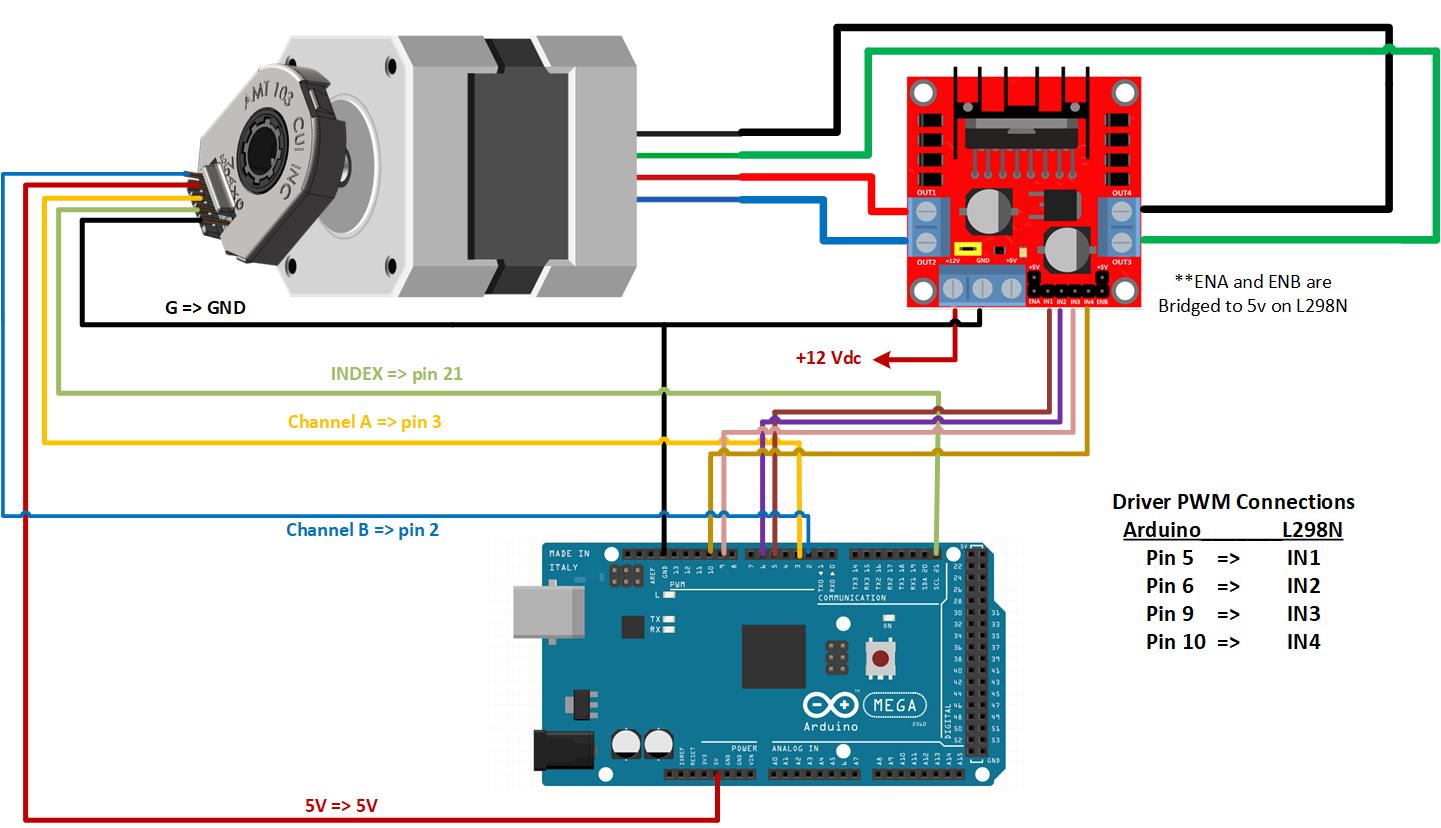

I have been trying to implement a closed angle control loop using a stepper motor but have run into some unexpected behavior. My current setup includes an Arduino Mega 2560, L298N motor driver, a 0.9 deg/step bipolar stepper motor and an AMT103-V capacitive encoder. I have the motor driver powered at 12v from a variable benchtop power supply. I have set my encoder for 512 ppr.

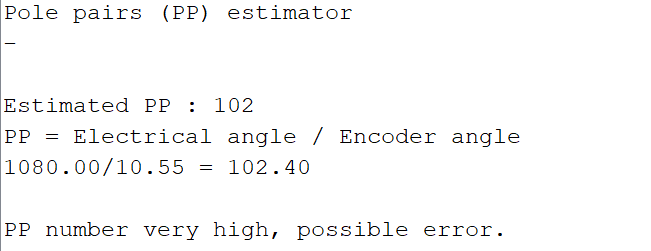

I have an application that requires a positional control loop and backdrivability. When attempting to run this example from the SimpleFOCDocs I have encountered erratic jittering when using MotionControlType::angle and no motion or holding torque when attempting to use MotionControlType::torque. When calculating the pole pair number for my motor, I used the following equation: pole_pair = (steps/rotation) / 4; In my case, (400 steps/rev) / 4 = 100 PP, however when I set StepperMotor motor = StepperMotor(100); I get a failed PP check when running the code shown below, and a changing estimation that is always higher than the calculated value.

Assuming I had miscalculated the PP number, I tried using find_pole_pairs_number under Simple FOC>utils>calibration>find_pole_pair_number>encoder>find_pole_pairs_number. This yields something like this:

When using StepperMotor motor = StepperMotor(102); (or whatever the estimated PP) I still get the erratic behavior, as seen in the clip below:

https://youtu.be/bVqnWa4HgVQ

The motor heats up, and when the rotor is moved it begins to jump erratically until it settles again, usually in a random angle. Additionally, the index search I believe should be one full rotation, but as you can see in the clip is far less than that.

I have tried running the same setup with MotionControlType::angle_openloop and MotionControlType::velocity_openloop, using the same setup and both worked as expected.

I have also tried:

- Running the setup with/without index pin on encoder

- Running the example using a Nucleo-64 board (as in the example)

- Changing encoder resolution (tried 2048 PPR and 512 PPR)

- Changing the PID gains

I believe that I am misunderstanding something about the functionality seen in the code I am running below. If anyone has any ideas on why this is happening, let me know!

#include <SimpleFOC.h>

// Stepper motor instance

StepperMotor motor = StepperMotor(102);

// Stepper driver instance

StepperDriver4PWM driver = StepperDriver4PWM(5, 6, 9, 10);

// encoder instance

Encoder encoder = Encoder(2, 3, 512, 21);

// channel A and B callbacks

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

void doIndex(){encoder.handleIndex();}

// commander interface

Commander command = Commander(Serial);

void onMotor(char* cmd){ command.motor(&motor, cmd); }

void setup() {

// initialize encoder sensor hardware

encoder.init();

encoder.enableInterrupts(doA, doB, doIndex);

// link the motor to the sensor

motor.linkSensor(&encoder);

// choose FOC modulation

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// power supply voltage [V]

driver.voltage_power_supply = 12;

driver.init();

// link the motor to the sensor

motor.linkDriver(&driver);

// set control loop type to be used

motor.controller = MotionControlType::angle;

// controller configuration based on the control type

motor.PID_velocity.P = 0.2;

motor.PID_velocity.I = 10;

motor.PID_velocity.D = 0;

// default voltage_power_supply

motor.voltage_limit = 12;

// velocity low pass filtering time constant

motor.LPF_velocity.Tf = 0.01;

// angle loop controller

motor.P_angle.P = 20;

// angle loop velocity limit

motor.velocity_limit = 50;

// use monitoring with serial for motor init

// monitoring port

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialise motor

motor.init();

// align encoder and start FOC

motor.initFOC();

// set the initial target value

motor.target = 1;

// define the motor id

command.add('M', onMotor, "motor");

// Run user commands to configure and the motor (find the full command list in docs.simplefoc.com)

Serial.println(F("Motor commands sketch | Initial motion control > torque/voltage : target 2V."));

_delay(1000);

}

// set the initial target value

float target_angle = 1;

long timestamp_us = _micros();

void loop() {

// iterative setting FOC phase voltage

motor.loopFOC();

// iterative function setting the outter loop target

// velocity, position or voltage

// if tatget not set in parameter uses motor.target variable

motor.move();

// real time monitoring calls

//motor.monitor();

// user communication

//command.run();

}

Thank you!

Michael L.