Hello everyone,

I am trying to build a very basic setup with an ESP32 + AS5600 + GBM2804H-100T + SimpleFOC board, working in any closed loop mode (torque, velocity, angle). However I am facing an issue that got me completely lost.

I am able to run the project in open loop modes (angle and velocity) without any problem (small video x.com).

But, when I try to set any closed loop modes it will fail with either vibrating or idling. I can rotate the motor with my hands, and while doing so, from time to time it jumps to another angle.

I have checked:

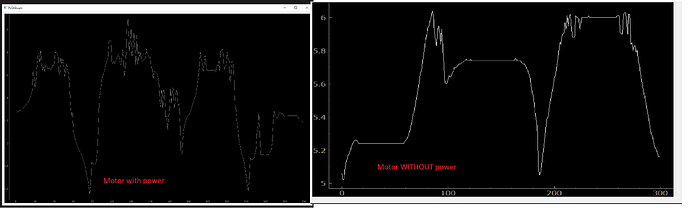

- The magnet of the AS5600: I can read the position perfectly, and for the whole rotation.

- I have tried changing the poles / coil resistance parameters.

- Played with PID tunning for angle and velocity

- Downsampling the movements/measurements

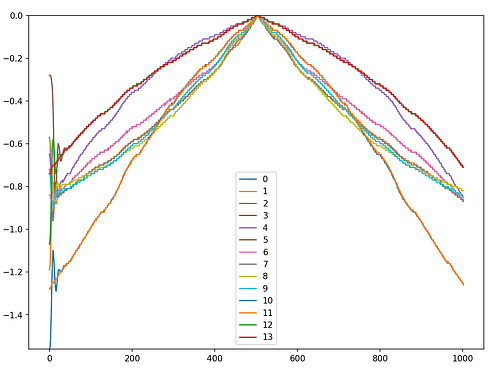

One thing to note is that the PP almost always fails, and the example to get the polepairs almost always return negative values, and when it returns a positive value dont event turn after gettting it.

I can add a connection diagram but, since the movement and sensor is working I understand the AS5600 and the motor are working nice.

Anyone has any idea what can I test next? What can I change?

#define ESP_H

#include <Arduino.h>

#include "SimpleFOC.h"

MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0x0E, 4);

BLDCMotor motor = BLDCMotor(7);

BLDCDriver3PWM driver = BLDCDriver3PWM(18, 4, 5,19);

Commander command = Commander(Serial);

void doMotor(char* cmd) { command.motor(&motor, cmd); }

void setup() {

Serial.begin(115200);

sensor.init();

Serial.println("AS5600 ready");

driver.pwm_frequency = 20000;

// power supply voltage [V]

driver.voltage_power_supply = 12;

// Max DC voltage allowed - default voltage_power_supply

driver.voltage_limit = 4;

// driver init

driver.init();

Serial.println("Driver ready");

motor.linkSensor(&sensor);

motor.linkDriver(&driver);

motor.useMonitoring(Serial);

motor.controller = MotionControlType::torque;

motor.init();

motor.initFOC();

command.add('M', doMotor, "motor");

}

void loop() {

motor.loopFOC();

motor.move();

motor.monitor();

command.run();

}