This is an interesting discussion, for sure!

I think this is a completely orthogonal topic. The 3rd harmonic injection is a modulation technique to boost the voltage, and can be used with any winding configuration.

I think it makes more sense to examine the situation under block (6-step) commutation - a more simple commutation technique where we don’t need the PWM to generate waveforms, here shown for a normal 3-half bridge configuration and a motor with wye winding:

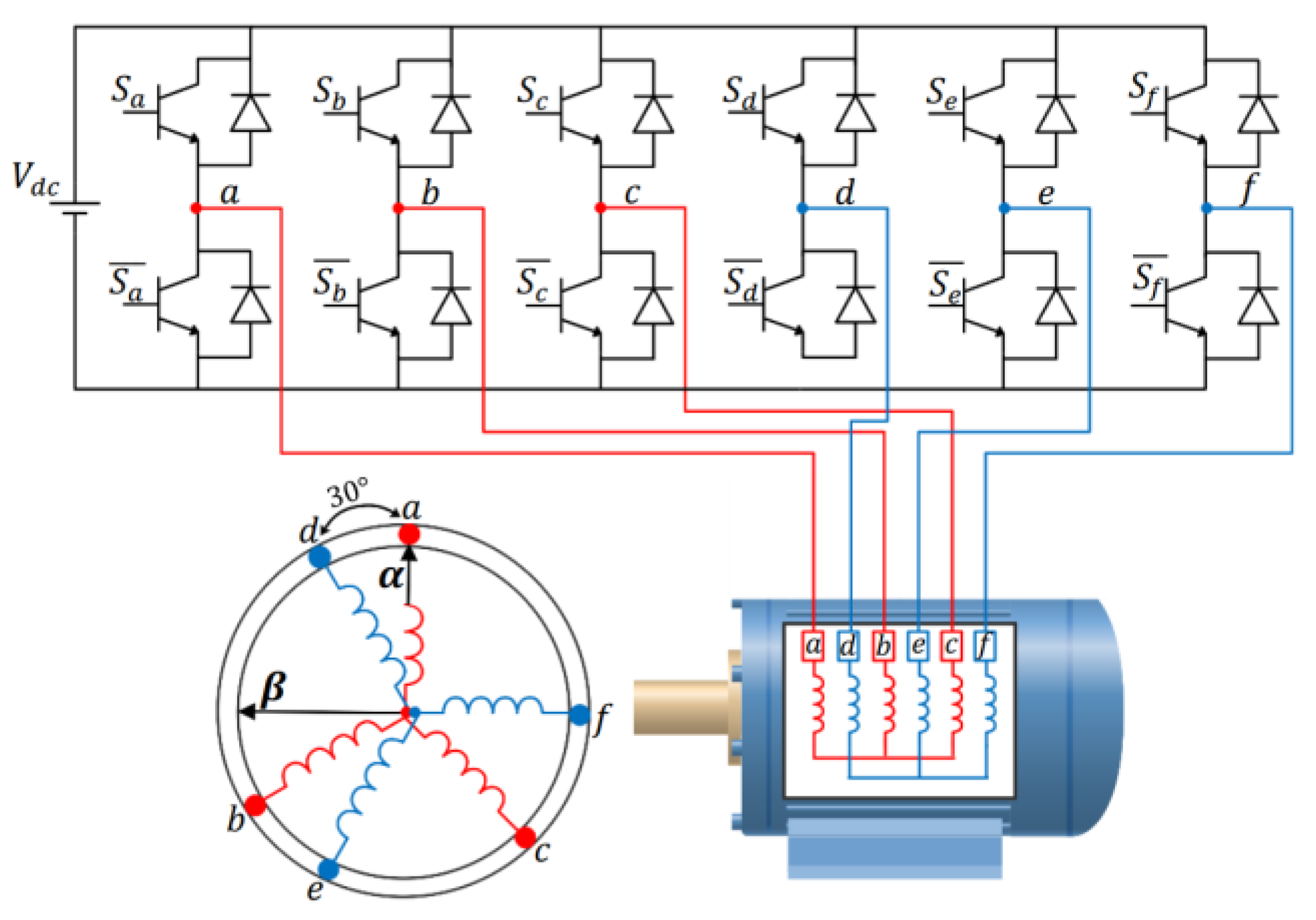

@serkan 's configuration would be this:

where L1, L2 and L3 are the motor windings, neither wye, nor delta, but each winding connected to its own full bridge.

If we compare this to the wye motor image above, and look at the block commutation pattern, then we can compare the voltages through the windings, looking at the yellow highlighted sector 3 for example:

3 half bridges:

Phase A (blue): Q1 OFF Q2 OFF = High Z

Phase B (green): Q2 ON Q3 OFF = 24V

Phase C (red): Q4 OFF Q5 ON = GND

The effect:

Phase A: High Z

Phase B: 24V (from VBUS to star point)

Phase C: -24V (from GND to star point)

3 full bridges:

Phase A (L1): Q1, Q2, Q3, Q4 all OFF = High Z

Phase B (L2): Q5 ON Q6 OFF Q7 OFF Q8 ON = 24V

Phase C (L3): Q9 OFF Q10 ON Q11 ON Q12 OFF = -24V

The effect:

Phase A: High Z

Phase B: 24V (Q5->Q8 from left to right)

Phase C: -24V (Q11->Q10 from right to left)

So we see the effect is the same, as @Andrew and @Antun_Skuric have already said.

What will be different is the amount of current that flows through the windings. Assuming we use the same windings in each configuration, the motors will exhibit different resistances:

- the wye motor will have 2x the winding resistance, as the current has to flow through two windings in series.

- the “3 full bridge” motor would have 1x winding resistance, each winding being by itself.

- the delta wound motor in Andrew’s example would have 2/3 x winding resistance, as the windings are energized in a parallel configuration.

In practice, I’ve never seen a motor that uses 3 full bridges. Using the 3 full bridges would need more control wires and need double the hardware in terms of the FETs and gate drivers.

Actually I think my conclusion is correct but my description of what’s going on with the phase voltages is still wrong. I’ll edit it tomorrow when I’m less tired…