Hello community,

I am trying to create a haptic force feedback device with a bldc motor. On the motor is a thread which winds up a string by the rotary motion of the motor (see Image_1). By pulling the string I want to simulate constant forces. Unfortunately, i’m not getting a perfect constant force while pulling the string because I feel one jerk/cogging (caused by the poles?) every full revolution. Do you guys have any idea how I could manage to drive the motor with a constant force against its direction of rotation? Is this possible with a BLDC motor?

Motor: iPower Motor GM3506 (AS5048A Encoder)

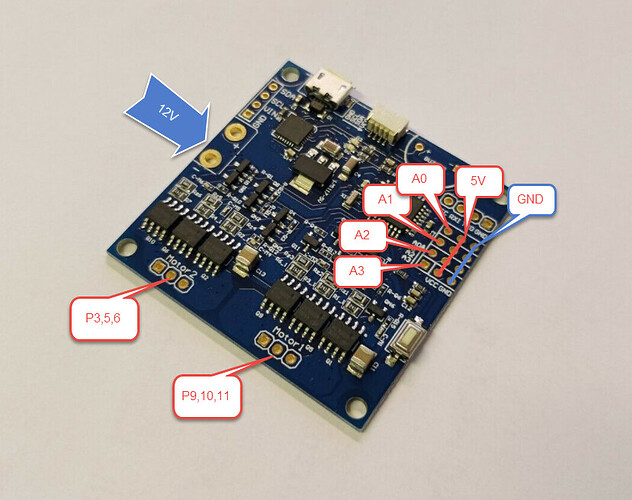

Board: Arduino Pro based BLDC Controller (Arduino Pro - based Brushless motor controller driver board (FOC BLDC servo). | eBay )

Image_1:

Code:

#include <SimpleFOC.h>

MagneticSensorPWM sensor = MagneticSensorPWM(A0, 4, 928);

// BLDC motor & driver instance

BLDCMotor motor = BLDCMotor(11);

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 10, 11);

// voltage set point variable

float target_voltage = 2;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&target_voltage, cmd);}

void setup() {

// initialise magnetic sensor hardware

sensor.init();

// link the motor to the sensor

motor.linkSensor(&sensor);

// power supply voltage

driver.voltage_power_supply = 8;

driver.init();

motor.linkDriver(&driver);

// aligning voltage

motor.voltage_sensor_align = 5;

// choose FOC modulation (optional)

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set motion control loop to be used

motor.controller = MotionControlType::torque;

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add target command T

command.add('T', doTarget, "target voltage");

Serial.println(F("Motor ready."));

Serial.println(F("Set the target voltage using serial terminal:"));

_delay(1000);

}

void loop() {

motor.loopFOC();

motor.move(target_voltage);

command.run();

}

With this code I feel a jerk/cogging every full rotation… ![]()

Thank you for your help! ![]()

Best, Fausto