Hello everyone !

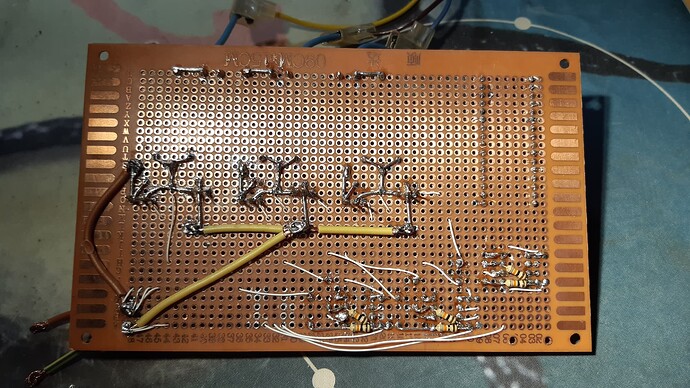

Im trying to build a basic bldc motor controller to work with simpleFOC. Its a simple circuit, and in the begining i was using IR2101 drivers. While testing the controller in open loop 6pwm, at first sight everything seemed to work fine. Some very minor stutters but the motor was rotating nicely, with good torque and speed. But after some more testing the drivers started to burn and were one by one stopping to work. I thought it was a problem with the circuit but couldnt find any. I decided to change the drivers to ir2103 with shoot through protection. To my big suprise after doing that the controller stopped working at all. No motor rotation and no current draw. But the nucleo is definetly sending signalas to the drivers, and the drivers definetly have the right Vcc. So of course the first conclusion was that there is a shoot through.

I had no other ideas left, so i decided to check the pwm signals that the STM is generaiting. I dont Have an osciloscope but i used a poor mans scope, made with an arduino.

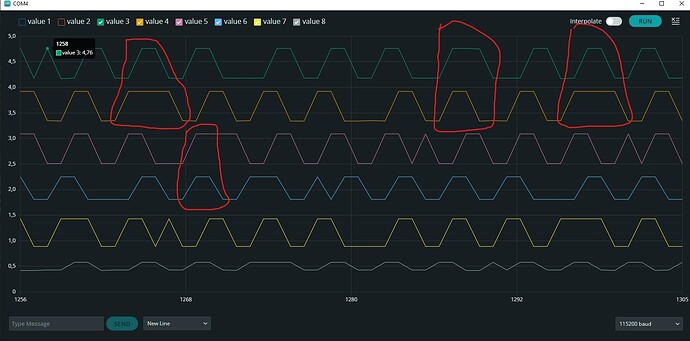

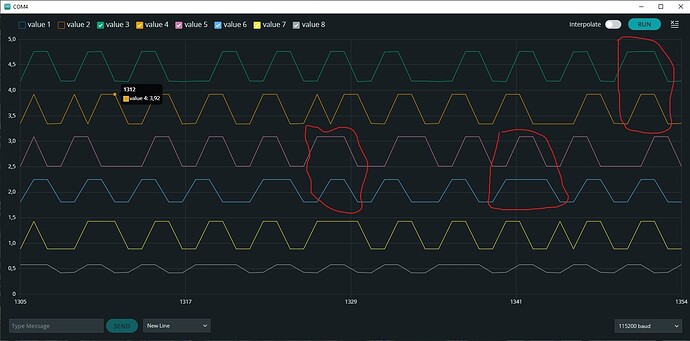

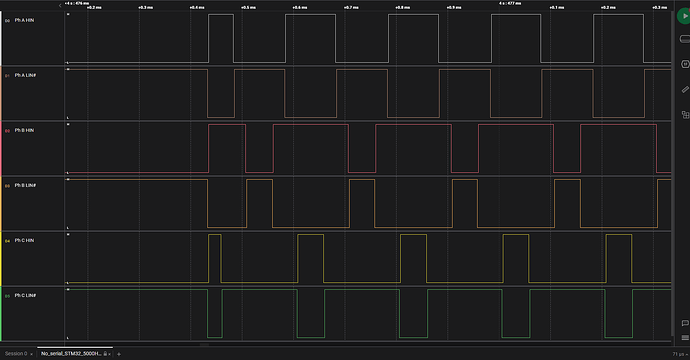

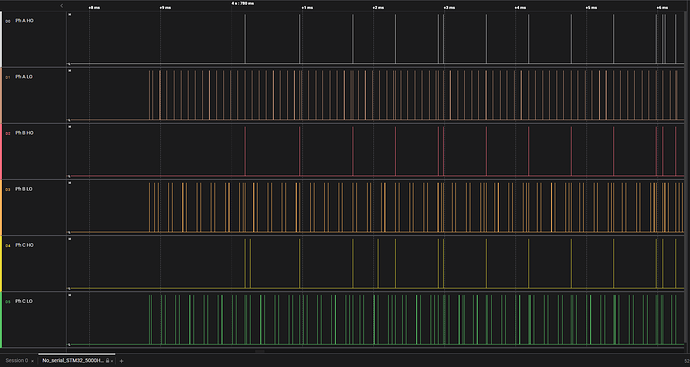

These are 2 random screens from the same test. The charts represent the voltages on each pwm pin starting from the top. So the top chart is Phase A High, the second chart from the top is Ph A Low, and so on.

It’s not a perfect solllution but ther are visible moments when both, the High and Low pin, on the same halfbridge driver, are open at the same time. Can this be the reason there actually is a shoot through ?

Also

The voltages on the represented chart are not calibrated but i tested each one separetly, and they all equal 3.5V in high and 0.4V in low. With exception of the last chart becouse the Ph C low pin does not give out any signal for some reason.

I tested many different codes, changed parameters, reinstalled IDE and the libraries so i tried all the basic stuff. Might this be a problem with my pc config or the stm compatibility? It just looks like a very random problem ;/ .

Is anyone able to give me a hint what might be the thing causing this weird behavior? I searched through the forum and it seemed like nobody had a bug like that.

Gratefull for all the help!