#include <SimpleFOC.h>

// BLDC motor & driver instance

BLDCMotor motor = BLDCMotor(22, 1.2);

// BLDCDriver6PWM driver = BLDCDriver6PWM(pwm HIGH , pwm LOW , pwmHIGH , pwm LOW , pwm HIGH , pwm LOW );

BLDCDriver6PWM driver = BLDCDriver6PWM(PA8 , PB13 , PA9 , PB14 , PA10 , PB15 );

// InlineCurrentSensor constructor

// - mVpA - mV per Amp ratio

// - phA - A phase adc pin

// - phB - B phase adc pin

// - phC - C phase adc pin (optional)

//InlineCurrentSense current_sense = //InlineCurrentSense(40.0, PB0 , PC1 , PC0 );

// hall sensor instance

HallSensor sensor = HallSensor(PB3, PB4, PB5, 22);

// Interrupt routine intialisation

// channel A and B callbacks

void doA(){sensor.handleA();}

void doB(){sensor.handleB();}

void doC(){sensor.handleC();}

// voltage set point variable

float target_voltage = 0;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget (char* cmd){ command.scalar (&target_voltage, cmd); }

void setup() {

// initialize encoder sensor hardware

sensor.init();

sensor.enableInterrupts(doA, doB, doC);

// link the motor to the sensor

motor.linkSensor(&sensor);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 65;

driver.init();

// link the driver to the current sense

//current_sense.linkDriver(&driver);

// link driver

motor.linkDriver(&driver);

// aligning voltage

motor.voltage_sensor_align = 3;

// init current sense

//current_sense.init();

// init current sense

//if (current_sense.init()) Serial.println(“Current sense init success!”);

//else{

// Serial.println(“Current sense init failed!”);

// return;

}

// link motor and current sense

// motor.linkCurrentSense(¤t_sense);

// choose FOC modulation (optional)

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set torque mode:

//motor.torque_controller

//TorqueControlType::foc_current;

// set motion control loop to be used

motor.controller = MotionControlType::torque;

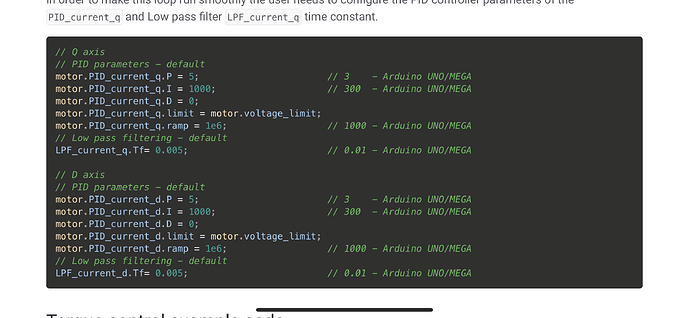

// foc current control parameters (Arduino UNO/Mega)

//motor.PID_current_q.P = 5;

//motor.PID_current_q.I= 1000;

//motor.PID_current_d.P= 5;

//motor.PID_current_d.I = 1000;

//motor.LPF_current_q.Tf = 0.005;

//motor.LPF_current_d.Tf = 0.005;

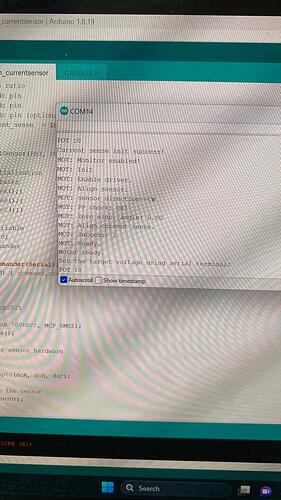

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add target command T

command.add(‘T’, doTarget, “target voltage”);

Serial.println(F(“Motor ready.”));

Serial.println(F(“Set the target voltage using serial terminal:”));

_delay(1000);

}

void loop() {

motor.loopFOC();

motor.move(target_voltage);

command.run();

}