Hi,@Antun_Skuric.

Nice to see you again ,And thank guys for your reply

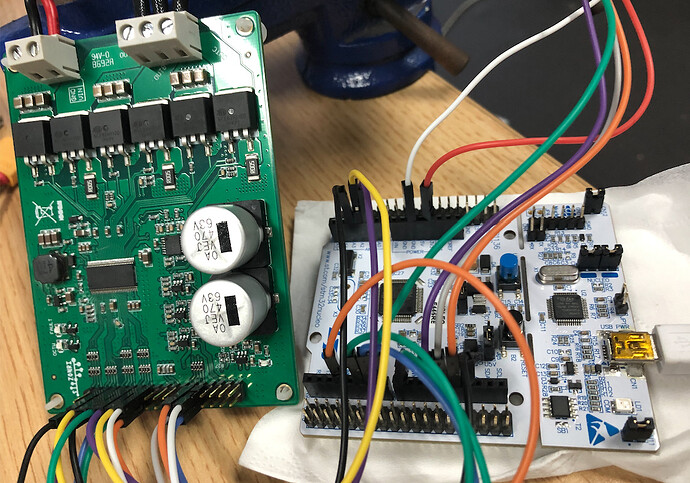

I’m sorry I didn’t post these days. ![]()

And I’m busy with my work recently. I’ll record a detailed video in a few days to describe the problem. ![]()

Hi,guys.

I recorded the serial monitor and the motor together today,If there are any problems, I will continue to improve, thanks everyone.

This is my code.

#include "SimpleFOC.h"

#define EN_GATE 8

#define M_PWM A1

#define M_OC A2

#define OC_ADJ A3

// The cs is Pin7,board is simplebgc mos v1.3

MagneticSensorSPI sensor = MagneticSensorSPI(7, 14, 0x3FFF);

// magnetic sensor instance

// MagneticSensorSPI sensor = MagneticSensorSPI(10, 14, 0x3FFF);

// magnetic sensor instance

//MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0x0E, 4);

// Motor instance

// BLDCMotor motor = BLDCMotor(9, 5, 6, 7, 8);

// Motor instace(Simplebgc v1.3) (MOT1 9,10,11;MOT2 3,5,6)

BLDCMotor motor = BLDCMotor(3, 5, 6, 14, 8);

void setup() {

// initialise magnetic sensor hardware

sensor.init();

// link the motor to the sensor

motor.linkSensor(&sensor);

// DRV8302 specific code

// M_OC - enable overcurrent protection

pinMode(M_OC,OUTPUT);

digitalWrite(M_OC,LOW);

// M_PWM - enable 3pwm mode

pinMode(M_PWM,OUTPUT);

digitalWrite(M_PWM,HIGH);

// OD_ADJ - set the maximum overcurrent limit possible

// Better option would be to use voltage divisor to set exact value

pinMode(OC_ADJ,OUTPUT);

digitalWrite(OC_ADJ,HIGH);

//

//12V

motor.voltage_power_supply = 12;

// set motion control loop to be used

motor.controller = ControlType::velocity;

motor.PI_velocity.P = 0.001;

motor.PI_velocity.I = 0.2;

//

motor.PI_velocity.voltage_limit = 3;

motor.PI_velocity.voltage_ramp = 1000;

motor.LPF_velocity.Tf = 0.01;

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

//

motor.voltage_sensor_align = 0.1;

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

Serial.println("Motor ready.");

Serial.println("Set the target velocity using serial terminal:");

_delay(1000);

}

// velocity set point variable

float target_velocity = 0;

// utility function enabling serial communication with the user to set the target values

// this function can be implemented in serialEvent function as well

void serialReceiveUserCommand() {

// a string to hold incoming data

static String received_chars;

while (Serial.available()) {

// get the new byte:

char inChar = (char)Serial.read();

// add it to the string buffer:

received_chars += inChar;

// end of user input

if (inChar == '\n') {

// change the motor target

target_velocity = received_chars.toFloat();

Serial.print("Target velocity: ");

Serial.println(target_velocity);

// reset the command buffer

received_chars = "";

}

}

}

void loop() {

//unsigned int timecnt;

// main FOC algorithm function

// the faster you run this function the better

// Arduino UNO loop ~1kHz

// Bluepill loop ~10kHz

//timecnt = millis()-timecnt;//Read once before testing the function,The unit is us

motor.loopFOC();

// Motion control function

// velocity, position or voltage (defined in motor.controller)

// this function can be run at much lower frequency than loopFOC() function

// You can also use motor.move() and set the motor.target in the code

motor.move(target_velocity);

// function intended to be used with serial plotter to monitor motor variables

// significantly slowing the execution down!!!!

// motor.monitor();

// user communication

serialReceiveUserCommand();

// timecnt = millis()-timecnt;//Subtract the last result after the function test is completed

// Serial.print("timecnt=");//print the "timecnt"

// Serial.println(timecnt );

}

Your P is quite low. Are you tuning at low speed? I find it hard to tune P at low speed, instead i tune at half max speed (say 20 radians/s) and tune P first (holding i to zero). If P can give you 70% of target speed (i.e 14 rad/s) without oscillation, then later add I.

What was the clock speed of your mcu?