A great question, and if David has time to give some thoughts (or anyone) I would also be very interested…

I think KV is a kind of artificial measure that is determined by the motor’s impedance. I don’t think low KV motors necessarily have higher torque, just different torque-speed curves. You can get better torque out of them at lower speeds maybe?

Basically the way I see it, the current through the windings determines the strength of the magnetic field, and thus the (somehow theoretical) maximum torque.

But given sufficient voltage (again in theory) you can put any current through any winding (up to physical limits) - so the winding resistance determines how much voltage is needed to obtain a particular current, but also, and perhaps more importantly, the resistance is a component of the impedance, which determines how quickly the current can rise through the windings.

How all this relates to torque is even more complicated, since in a “static” situation, i.e. if the motor is not turning but the windings are energised, the magnetic pull will be “outwards from the centre”, and the torque in terms of rotation will be quite low.

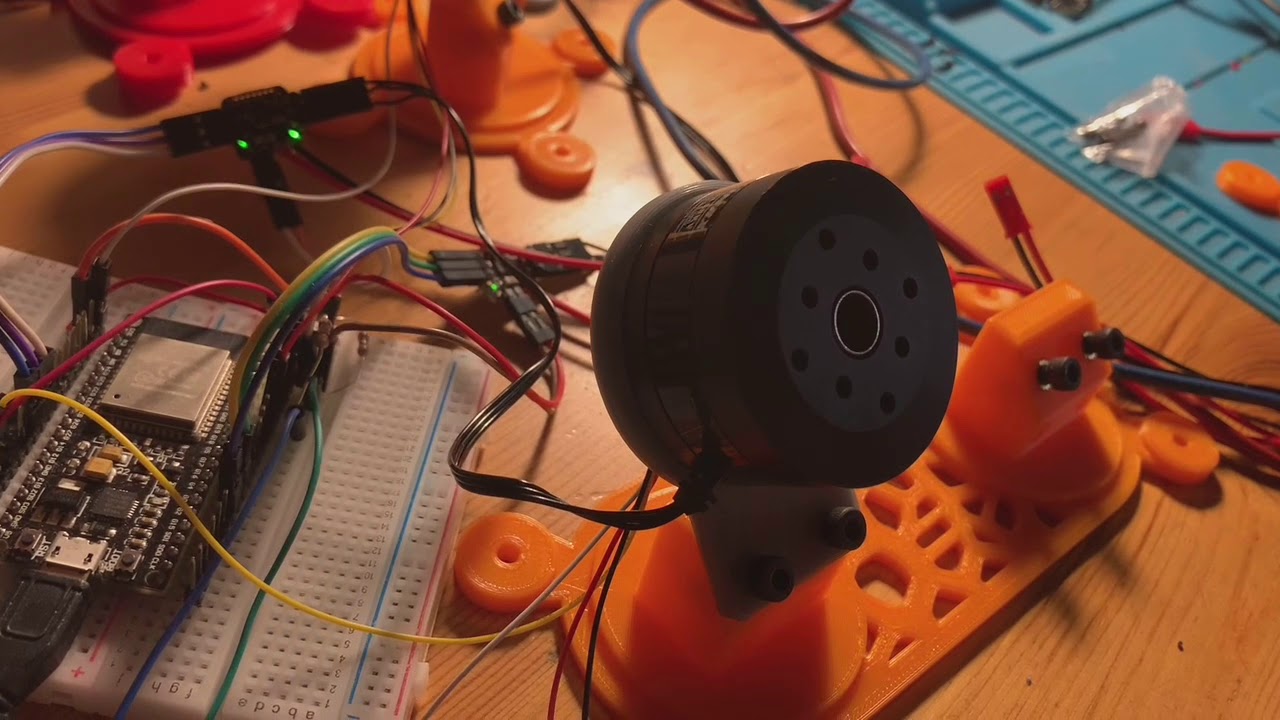

To turn the motor, you energise (commutate) the windings in such a way that the magnetic pull acts “sideways” on the rotor, ideally at 90deg (electrical angle). By doing this in exactly the right pattern and speed to always match the rotors current position, and keeping the electrical angle at always 90deg, you “pull” the rotor around with maximum torque - that’s what’s so cool about SimpleFOC.

So I think the winding resistance has more to do with the speed you can attain - low winding resistance means lower impedance, means faster rise-time of the current. And if the resistance is too low, it means the current can easily rise too high, and everything (motor, cables, PCB traces, MOSFETs, etc…) can burn up, unless you build in some protection. But it also means you can spin the motor quickly with good torque, since each (short) commutation step will deliver enough current.

On the other hand high-ohm windings mean slower speeds, and if the resistance is high enough, it simplifies the control electronics and software because you don’t need the current limiting. It also means you can “hold” positions better, and presumably it is easier to commutate the motor slowly and smoothly.

This is why these motors are used more with SimpleFOC, because the current limiting is work in development, and you can run the gimbal motors at their native voltage without fear of burning things down. Low ohm windings have to be run at very low voltages, which comes with its own set of problems…

![]()