Hello

I’m having some issues getting my stepper motor working properly.

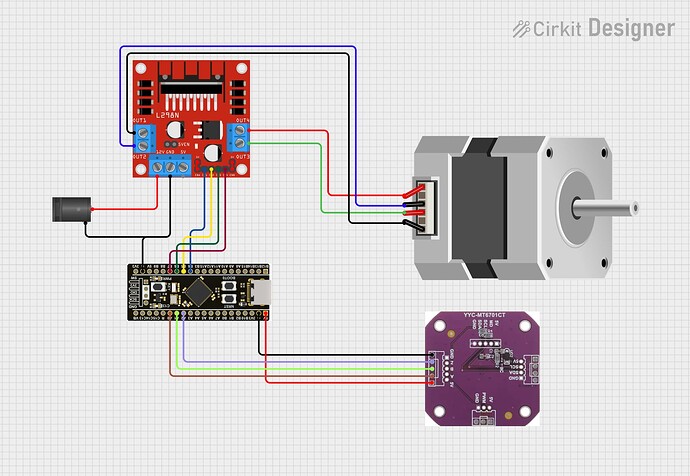

Setup

stepper motor + MT6701 (ABZ) + L298N + STM32F401 black pill

- My encoder test script shows a CPR of 4096.

- It’s a standard 200 pulses/rotation stepper so 50 PP.

- LCR-T4 shows 3 Ω, 4 mH (green-red and blue-black, these values in code don’t help)

Code

#include <SimpleFOC.h>

// Stepper motor instance StepperMotor(polepairs, (R), (KV))

StepperMotor motor = StepperMotor(50);

// Stepper driver instance StepperDriver4PWM(ph1A, ph1B, ph2A, ph2B, (en1), (en2))

StepperDriver4PWM driver = StepperDriver4PWM(PB4, PB5, PB6, PB7);

// position / angle sensor instance Encoder(encA, encB , cpr, (index))

Encoder sensor = Encoder(PA0, PA1, 4096);

void doA(){sensor.handleA();}

void doB(){sensor.handleB();}

// commander instance

Commander command = Commander(Serial);

void doTarget(char* cmd){command.motion(&motor, cmd);}

void setup() {

// start serial

Serial.begin(115200);

// initialize sensor

sensor.init();

// enable encoder interrupts

sensor.enableInterrupts(doA, doB);

// link sensor to motor

motor.linkSensor(&sensor);

// initialize driver

driver.init();

// link driver to motor

motor.linkDriver(&driver);

// set control loop type to be used

motor.controller = MotionControlType::angle;

// controller configuration based on the control type

motor.PID_velocity.P = 0.2;

motor.PID_velocity.I = 20;

motor.PID_velocity.D = 0.001;

// velocity low pass filtering time constant

motor.LPF_velocity.Tf = 0.01;

// angle loop controller

motor.P_angle.P = 20;

// set torque control type to voltage (default)

motor.torque_controller = TorqueControlType::voltage;

// use monitoring

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add command to commander

command.add('M', doTarget, "target");

_delay(1000);

}

void loop() {

// main FOC algorithm function

// the faster you run this function the better

motor.loopFOC();

// this function can be run at much lower frequency than loopFOC()

motor.move();

// significantly slowing the execution down

motor.monitor();

// user communication

command.run();

}

I had some HF vibration issues last time I used a stepper motor, so I added the PID gains.

The problem

When I run the code, I get:

MOT: Align sensor.

MOT: sensor_direction==CW

MOT: PP check: fail - estimated pp: 207.39

MOT: Zero elec. angle: 5.52

MOT: No current sense.

MOT: Ready.

It does something because when I try to turn the motor by hand, it locks it and the current limit of my PSU kicks in.

When I change the polepairs to 200, it ‘works’:

MOT: Align sensor.

MOT: sensor_direction==CCW

MOT: PP check: OK!

MOT: Zero elec. angle: 3.45

MOT: No current sense.

MOT: Ready.

With ‘works’ I mean that the calibration works (even though the calibration move is small, I don’t know if that’s to be expected and can be edited?) and I can move the motor with the commander interface but when I enter M1, it only moves a little over half a turn, and it’s the same for M2, M3, … .

All ideas are welcome.

Thanks

Stijn