Hi @runger,

I using a nema17 2 phase motor, 4 wires. I connected the Out 1,2 to A1,A2 and Out 3,4 to B1,B2 respectively.

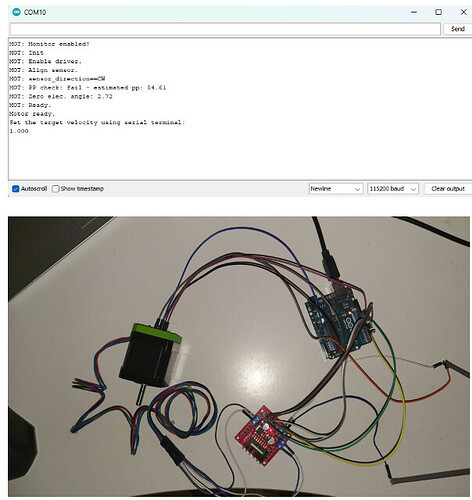

Serial monitor output:

PP check result is kind of random. It fluctuates. It works sometimes for the same input.

I tried lowering the voltage limit to 1 volt and the motor does not move.

Closed loop, open loop velocity and torque control examples I tried.

#include <SimpleFOC.h>

// magnetic sensor instance - SPI

//MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, 10);

// magnetic sensor instance - I2C

MagneticSensorI2C sensor = MagneticSensorI2C(AS5600_I2C);

// magnetic sensor instance - analog output

// MagneticSensorAnalog sensor = MagneticSensorAnalog(A1, 14, 1020);

// BLDC motor & driver instance

//BLDCMotor motor = BLDCMotor(11);

//BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

// Stepper motor & driver instance

StepperMotor motor = StepperMotor(50);

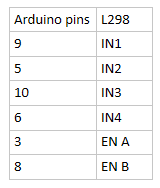

StepperDriver4PWM driver = StepperDriver4PWM(9, 5, 10, 6, 3, 8);

// voltage set point variable

float target_voltage = 2;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&target_voltage, cmd); }

void setup() {

digitalWrite(11,OUTPUT);

// digitalWrite(3,OUTPUT);

// digitalWrite(8,OUTPUT);

digitalWrite(11,HIGH);

// digitalWrite(3,HIGH);

// digitalWrite(8,HIGH);

// initialise magnetic sensor hardware

sensor.init();

Wire.setClock(100000);

// link the motor to the sensor

motor.linkSensor(&sensor);

// power supply voltage

driver.voltage_power_supply = 12;

driver.init();

motor.linkDriver(&driver);

// aligning voltage

motor.voltage_sensor_align = 5;

// choose FOC modulation (optional)

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set motion control loop to be used

motor.controller = MotionControlType::torque;

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add target command T

command.add(‘T’, doTarget, “target voltage”);

Serial.println(F(“Motor ready.”));

Serial.println(F(“Set the target voltage using serial terminal:”));

_delay(1000);

}

void loop() {

// main FOC algorithm function

// the faster you run this function the better

// Arduino UNO loop ~1kHz

// Bluepill loop ~10kHz

motor.loopFOC();

// Motion control function

// velocity, position or voltage (defined in motor.controller)

// this function can be run at much lower frequency than loopFOC() function

// You can also use motor.move() and set the motor.target in the code

motor.move(target_voltage);

// user communication

command.run();

}