Hello,

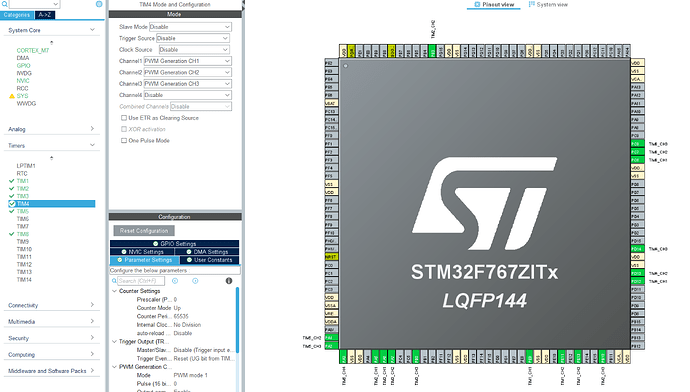

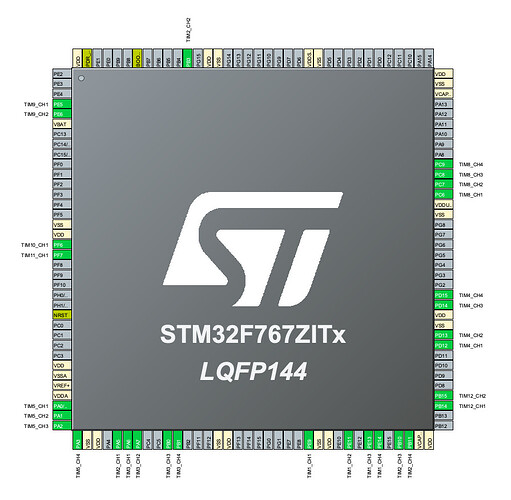

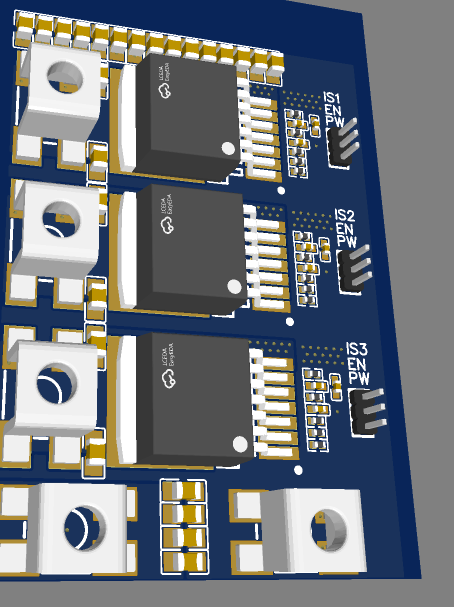

Recent questions made me curious if/how the library can support more than one motor on a 3PWM timer set. I used STM32F767 and wrote a simple open loop for the six timers supporting PWM on a single timer per set.

It appears that any timer combination is limited to only three motors at a time. Adding any fourth motor regardless of the channel halts the MCU within the

driver.init();

step, and thus the whole MCU hangs.

Is there a hard limit on three instances of the driver, or this is some inherent bug just applicable to STM32?

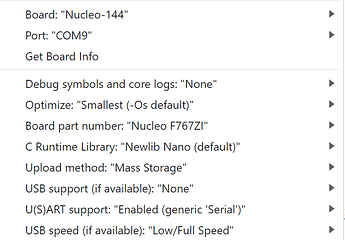

Below is the code I used for Nucleo-144 STM32F767ZI

Any input would be highly appreciated. I can test whatever you discover/change/fix.

Open loop motor control example for six motors.

Please uncomment any motor after the init to trigger the hangup.

Perhaps I’m doing something wrong?

#include <SimpleFOC.h>

BLDCMotor motor1 = BLDCMotor(1);

BLDCMotor motor2 = BLDCMotor(1);

BLDCMotor motor3 = BLDCMotor(1);

BLDCMotor motor4 = BLDCMotor(1);

BLDCMotor motor5 = BLDCMotor(1);

BLDCMotor motor6 = BLDCMotor(1);

BLDCDriver3PWM driver1 = BLDCDriver3PWM(PE9, PE11, PE13); //T1

BLDCDriver3PWM driver2 = BLDCDriver3PWM(PA5, PB3, PB10); //T2

BLDCDriver3PWM driver3 = BLDCDriver3PWM(PA6, PA7, PB0); //T3

BLDCDriver3PWM driver4 = BLDCDriver3PWM(PD12, PD13, PD14); //T4

BLDCDriver3PWM driver5 = BLDCDriver3PWM(PA1,PA2, PA3); //T5 (CH2,CH3,CH4)

BLDCDriver3PWM driver6 = BLDCDriver3PWM(PC6,PC7, PC8); //T8

//target variable

float target_velocity = 2;

float target_voltage = 5;

float maxVelo = 20; //rad/s

float maxVolt = 2;

//int analog_read_A0 = 0;

//int analog_read_A1 = 0;

unsigned long prev = 0;

unsigned long current = 0;

unsigned long threshold = 500;

void setup() {

driver1.voltage_power_supply = 12;

driver2.voltage_power_supply = 12;

driver3.voltage_power_supply = 12;

driver4.voltage_power_supply = 12;

driver5.voltage_power_supply = 12;

driver6.voltage_power_supply = 12;

driver1.pwm_frequency = 15000;

driver2.pwm_frequency = 15000;

driver3.pwm_frequency = 15000;

driver4.pwm_frequency = 15000;

driver5.pwm_frequency = 15000;

driver6.pwm_frequency = 15000;

//driver.enable_active_high = false; // Reverse logic driver, low is enable

// driver init creates a hangup for more than 3 drivers

//driver1.init();

driver2.init();

driver3.init();

driver4.init();

///driver5.init();

driver6.init();

//motor1.linkDriver(&driver1);

motor2.linkDriver(&driver2);

motor3.linkDriver(&driver3);

motor4.linkDriver(&driver4);

//motor5.linkDriver(&driver5);

motor6.linkDriver(&driver6);

//motor1.voltage_limit = target_voltage; // [V]

motor2.voltage_limit = target_voltage; // [V]

motor3.voltage_limit = target_voltage; // [V]

motor4.voltage_limit = target_voltage; // [V]

//motor5.voltage_limit = target_voltage; // [V]

motor6.voltage_limit = target_voltage; // [V]

//motor1.velocity_limit = target_velocity; // [rad/s] cca 50rpm

motor2.velocity_limit = target_velocity; // [rad/s] cca 50rpm

motor3.velocity_limit = target_velocity; // [rad/s] cca 50rpm

motor4.velocity_limit = target_velocity; // [rad/s] cca 50rpm

//motor5.velocity_limit = target_velocity; // [rad/s] cca 50rpm

motor6.velocity_limit = target_velocity; // [rad/s] cca 50rpm

//motor1.controller = MotionControlType::velocity_openloop;

motor2.controller = MotionControlType::velocity_openloop;

motor3.controller = MotionControlType::velocity_openloop;

motor4.controller = MotionControlType::velocity_openloop;

//motor5.controller = MotionControlType::velocity_openloop;

motor6.controller = MotionControlType::velocity_openloop;

//motor1.init();

motor2.init();

motor3.init();

motor4.init();

//motor5.init();

motor6.init();

_delay(500);

prev = millis();

current = millis();

}

void loop() {

//motor1.voltage_limit = target_voltage;

motor2.voltage_limit = target_voltage;

motor3.voltage_limit = target_voltage;

motor4.voltage_limit = target_voltage;

//motor5.voltage_limit = target_voltage;

motor6.voltage_limit = target_voltage;

//motor1.move(target_velocity);

motor2.move(target_velocity);

motor3.move(target_velocity);

motor4.move(target_velocity);

//motor5.move(target_velocity);

motor6.move(target_velocity);

}

Cheers,

Valentine