Hi.

My setup: 1.8 deg stepper motor 42STH60-1206A (nema 17), l298n, encoder Autonics E40H12-5000-6-L-5, 5000 ppr.

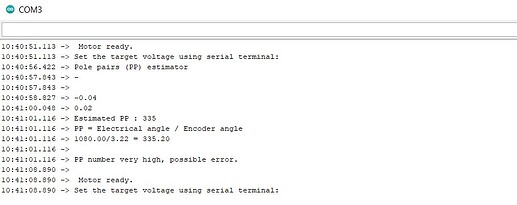

I’ve tried running example “find_pole_pairs_number”. The results are shown in the figure. After finding the poles, the motor starts to vibrate slightly and make noise. I tried to start the engine in angle_openloop mode, everything works fine. I also tested the encoder with the “encoder example”. Works fine too. What could be the problem?

Code

#include <SimpleFOC.h>

// Stepper motor instance

// its important to put pole pairs number as 1!!!

StepperMotor motor = StepperMotor(1);

StepperDriver4PWM driver = StepperDriver4PWM(PE9, PE11, PE13, PE14, PD0, PD1);

// Encoder(int encA, int encB , int cpr, int index)

Encoder encoder = Encoder(PA0, PA1, 5000);

// interrupt routine intialisation

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

void setup() {

encoder.quadrature = Quadrature::OFF;

// initialise encoder hardware

encoder.init();

// hardware interrupt enable

encoder.enableInterrupts(doA, doB);

// link the motor to the sensor

motor.linkSensor(&encoder);

// power supply voltage

// default 12V

driver.voltage_power_supply = 12;

driver.init();

motor.linkDriver(&driver);

// initialize motor

motor.init();

// monitoring port

Serial.begin(115200);

// pole pairs calculation routine

Serial.println("Pole pairs (PP) estimator");

Serial.println("-\n");

float pp_search_voltage = 6; // maximum power_supply_voltage/2

float pp_search_angle = 6*M_PI; // search electrical angle to turn

// move motor to the electrical angle 0

motor.controller = MotionControlType::angle_openloop;

motor.voltage_limit=pp_search_voltage;

motor.move(0);

_delay(1000);

// read the encoder angle

float angle_begin = encoder.getAngle();

Serial.println(angle_begin);

_delay(50);

// move the motor slowly to the electrical angle pp_search_angle

float motor_angle = 0;

while(motor_angle <= pp_search_angle){

motor_angle += 0.01;

motor.move(motor_angle);

}

_delay(1000);

// read the encoder value for 180

float angle_end = encoder.getAngle();

Serial.println(angle_end);

_delay(50);

// turn off the motor

motor.move(0);

_delay(1000);

// calculate the pole pair number

int pp = round((pp_search_angle)/(angle_end-angle_begin));

Serial.print(F("Estimated PP : "));

Serial.println(pp);

Serial.println(F("PP = Electrical angle / Encoder angle "));

Serial.print(pp_search_angle*180/M_PI);

Serial.print("/");

Serial.print((angle_end-angle_begin)*180/M_PI);

Serial.print(" = ");

Serial.println((pp_search_angle)/(angle_end-angle_begin));

Serial.println();

// a bit of monitoring the result

if(pp <= 0 ){

Serial.println(F("PP number cannot be negative"));

Serial.println(F(" - Try changing the search_voltage value or motor/encoder configuration."));

return;

}else if(pp > 30){

Serial.println(F("PP number very high, possible error."));

}else{

Serial.println(F("If PP is estimated well your motor should turn now!"));

Serial.println(F(" - If it is not moving try to relaunch the program!"));

Serial.println(F(" - You can also try to adjust the target voltage using serial terminal!"));

}

// set FOC loop to be used

motor.controller = MotionControlType::torque;

// set the pole pair number to the motor

motor.pole_pairs = pp;

//align encoder and start FOC

motor.initFOC();

_delay(1000);

Serial.println(F("\n Motor ready."));

Serial.println(F("Set the target voltage using serial terminal:"));

}

// uq voltage

float target_voltage = 2;

void loop() {

// main FOC algorithm function

// the faster you run this function the better

// Arduino UNO loop ~1kHz

// Bluepill loop ~10kHz

motor.loopFOC();

// Motion control function

// velocity, position or voltage (defined in motor.controller)

// this function can be run at much lower frequency than loopFOC() function

// You can also use motor.move() and set the motor.target in the code

motor.move(target_voltage);

// communicate with the user

serialReceiveUserCommand();

}

// utility function enabling serial communication with the user to set the target values

// this function can be implemented in serialEvent function as well

void serialReceiveUserCommand() {

// a string to hold incoming data

static String received_chars;

while (Serial.available()) {

// get the new byte:

char inChar = (char)Serial.read();

// add it to the string buffer:

received_chars += inChar;

// end of user input

if (inChar == '\n') {

// change the motor target

target_voltage = received_chars.toFloat();

Serial.print("Target voltage: ");

Serial.println(target_voltage);

// reset the command buffer

received_chars = "";

}

}

}