Good Afternoon,

I’m looking for some help in getting the torque control mode to work for a BLDC motor.

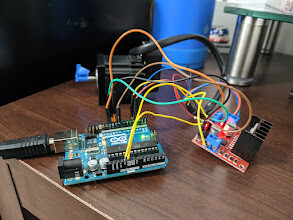

Hardware:

- Arduino UNO R3

- L298N (I know this is not ideal for BLDC motors, but it’s what I have right now)

- 3pp bldc motor with hall sensors motor datasheet

Circuit: right now I am powering everything off of the arduino 5V, I plan on getting a 12V power supply soon. Software interrupts are used for the hall sensors.

I am following the tutorial linked here: https://www.youtube.com/watch?v=ENGGh0ajE2M

I’ve been able to:

- Use open loop velocity to spin the motor up to 15 rad/s

- Read that the sensor measures 6.28 for a rotation of the motor

I’ve been trying to:

- Use the torque controller (motor doesn’t spin at all)

- Use the closed loop velocity controller (motor vibrates)

When the initFOC runs, the motor spins back and forth a few degrees, stops, and I get the following message:

MOT: Init

MOT: Monitor enabled!

MOT: Init

MOT: Enable driver.

MOT: Align sensor.

MOT: sensor_direction==CW

MOT: PP check: fail - estimated pp: 4.50

MOT: Zero elec. angle: 1.05

MOT: No current sense.

MOT: Ready.

Setup complete

Any help is greatly appreciated.

Code is largely copy+paste but is shown below:

#include <SimpleFOC.h>

#include <PciManager.h>

#include <PciListenerImp.h>

HallSensor sensor = HallSensor(2, 3, 4, 3); // hA, hB, hC, pole pairs

BLDCMotor motor = BLDCMotor(3);

BLDCDriver3PWM driver = BLDCDriver3PWM(11, 10, 9);

void doA(){sensor.handleA();}

void doB(){sensor.handleB();}

void doC(){sensor.handleC();}

PciListenerImp listenA(sensor.pinA, doA);

PciListenerImp listenB(sensor.pinB, doB);

PciListenerImp listenC(sensor.pinC, doC);

float target = 0.5;

void serialLoop() {

static String received_chars;

while (Serial.available()) {

char inChar = (char) Serial.read();

received_chars += inChar;

if (inChar == '\n') {

target = received_chars.toFloat();

Serial.print("Target = "); Serial.println(target);

received_chars = "";

}

}

}

void setup() {

Serial.begin(115200);

// Sensor setup

sensor.pullup = Pullup::USE_INTERN;

sensor.velocity_max = 500;

sensor.init();

PciManager.registerListener(&listenA);

PciManager.registerListener(&listenB);

PciManager.registerListener(&listenC);

// deactivate the OUT4 output

pinMode(8,OUTPUT);

digitalWrite(8,LOW);

// Motor Setup

driver.voltage_power_supply = 5;

driver.voltage_limit = 5;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

motor.voltage_limit = 5; // [V]

motor.velocity_limit = 18; // [rad/s]

//motor.voltage_sensor_align = 1;

motor.linkSensor(&sensor);

//motor.PID_velocity.P = 1.0;

//motor.PID_velocity.I = 0.0;

//motor.LPF_velocity.Tf = 0.01;

//motor.controller = MotionControlType::velocity;

motor.torque_controller = TorqueControlType::voltage;

motor.controller = MotionControlType::torque;

//motor.controller = MotionControlType::velocity_openloop;

motor.useMonitoring(Serial);

motor.init();

motor.initFOC();

Serial.println("Setup complete");

delay(1000);

}

void loop() {

serialLoop();

//motor.PID_velocity.P = target;

motor.loopFOC();

motor.move(target);

//sensor.update();

//Serial.print(sensor.getAngle());

//Serial.print("\t");

//Serial.println(sensor.getVelocity());

motor.monitor();

}