The serial monitor now outputs a success message and the motor is still not running.

I’m trying to run a BLDC motor using Arduino Mega and a simpleFOCShield. The motor I’m using is an EC 45 flat+Encoder. I used the example code from the Writing Code → Motion Control → Closed-Loop Control → Torque Control → FOC Current Mode tab, and only three codes were modified as shown below. But the motor didn’t turn.

BLDC motor motor = BLDC motor (9);

encoder encoder = encoder (2, 3, 2048);

driver.voltage_power_supply = 12;

Here’s the code I used.

=====================================================

#include <SimpleFOC.h>

// BLDC motor & driver instance

BLDCMotor motor = BLDCMotor(9);

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

// encoder instance

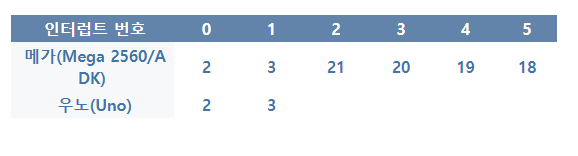

Encoder encoder = Encoder(2, 3, 2048);

// channel A and B callbacks

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

// current sensor

InlineCurrentSense current_sense = InlineCurrentSense(0.01, 50, A0, A2);

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&motor.target, cmd); }

void setup() {

// initialize encoder sensor hardware

encoder.init();

encoder.enableInterrupts(doA, doB);

// link the motor to the sensor

motor.linkSensor(&encoder);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 24;

driver.init();

// link driver

motor.linkDriver(&driver);

// current sense init hardware

current_sense.init();

// link the current sense to the motor

motor.linkCurrentSense(¤t_sense);

// set torque mode:

motor.torque_controller = TorqueControlType::foc_current;

// set motion control loop to be used

motor.controller = MotionControlType::torque;

// foc current control parameters (Arduino UNO/Mega)

motor.PID_current_q.P = 5;

motor.PID_current_q.I= 300;

motor.PID_current_d.P= 50;

motor.PID_current_d.I = 300;

motor.LPF_current_q.Tf = 0.01;

motor.LPF_current_d.Tf = 0.01;

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add target command T

command.add(‘T’, doTarget, “target current”);

Serial.println(F(“Motor ready.”));

Serial.println(F(“Set the target current using serial terminal:”));

_delay(1000);

}

void loop() {

motor.loopFOC();

motor.move(motor.target);

command.run();

}

=====================================================

The following messages were printed on the serial monitor.

MOT: Monitor enabled!

MOT: Init

MOT: Enable driver.

MOT: Align sensor.

MOT: sensor_direction==CCW

MOT: PP check: OK!

MOT: Zero elec. angle: 6.28

MOT: Align current sense.

Can you tell me what kind of problem you have?

- There seems to be no hardware problem because the motor rotated when operating using other example codes.