Hi,

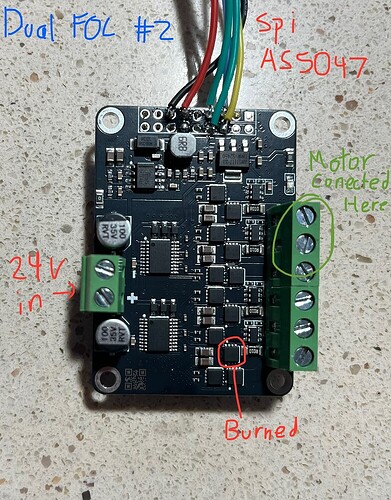

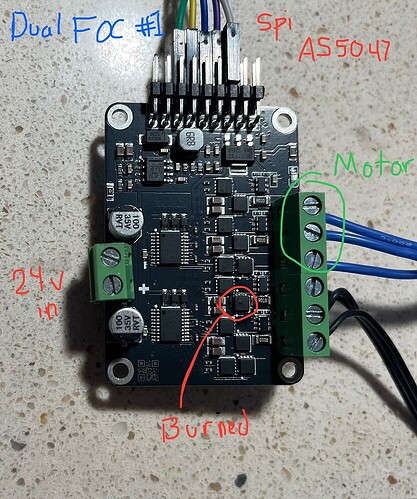

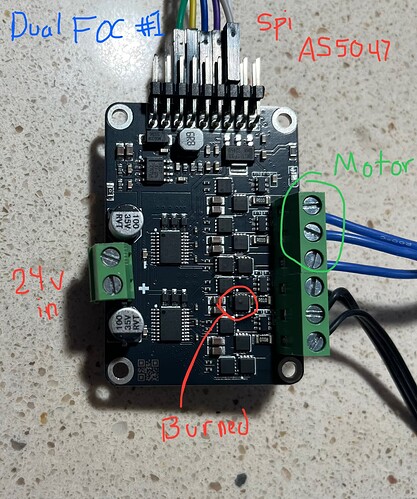

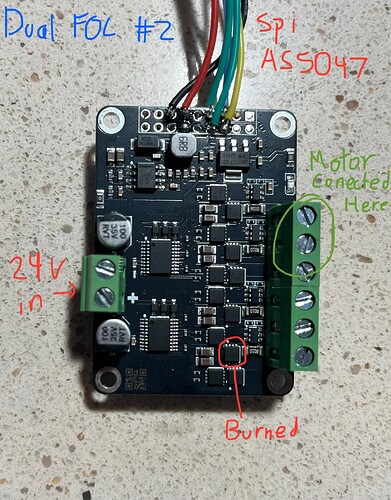

I have a set up consisting of a GM3506 gimbal motor with a MKS Dual FOC plus driver. Ive had issues with two separate boards burning up when driving a motor through the second driver with current torque control.

I had torque control working properly through the first driver(with a bit of jitter when holding position) but I ran into a severe issue when testing that same torque control mode with the second driver on the MKS board(A1,B1,C1). In the code the first driver is not enabled so the pins are left floating, but the second driver is properly enabled. And when I run the code and do some tests the MKS board burns out and then pulls 10Amps or so from the power supply. Ive had that happen with two separate boards. I am not sure what the issue is but I think it make be something with the first driver left floating.

Set up: I am driving the MKS Dual FOC plus board at 24 volts with a motor voltage limit of 12V. I am using the esp32 chip that comes with the Dual FOC board. The Gimbal motor has a resistance of 5.6Ω. The set up works if I’m driving the motor with the first driver, but if I switch to the second driver then the driver burned out

#include <Arduino.h>

#include <SimpleFOC.h>

// BLDC motor & driver instance

BLDCMotor motor = BLDCMotor(11);

//BLDCDriver3PWM driver = BLDCDriver3PWM(32, 33, 25, 22); ///MKS esp32

BLDCDriver3PWM driver = BLDCDriver3PWM(26, 27, 14, 12); //MKS esp32 // SECOND DRIVER (One with problem)

MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, 5);

//MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, 15);

// current sensor

//InlineCurrentSense current_sense = InlineCurrentSense(0.01f, 50.0f, 39, 36); //MKS esp32

InlineCurrentSense current_sense = InlineCurrentSense(0.01f, 50.0f, 35, 34); //MKS esp32 // SECOND DRIVER (One with problem)

float target_angle = 0;

float target_velocity = 0;

float current_limit;

unsigned long flagTime;

int flag = 1;

// instantiate the commander

Commander command = Commander(Serial);

/*

void doTarget(char* cmd) {

command.scalar(&motor.target, cmd);

}

*/

void doTarget(char* cmd) {

command.scalar(&target_angle, cmd);

}

void currentLim(char* cmd) {

command.scalar(¤t_limit, cmd);

motor.current_limit = current_limit;

motor.PID_velocity.limit = motor.current_limit;

}

void setup() {

// initialize encoder sensor hardware

sensor.init();

// link the motor to the sensor

motor.linkSensor(&sensor);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 24;

driver.voltage_limit = 24; // max voltage to motor

driver.init();

// link driver

motor.linkDriver(&driver);

// link the driver to the current sense

current_sense.linkDriver(&driver);

// current sense init hardware

current_sense.init();

current_sense.gain_b *= -1;

// link the current sense to the motor

motor.linkCurrentSense(¤t_sense);

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set torque mode:

motor.torque_controller = TorqueControlType::foc_current;

motor.current_limit = .5; // Amp limit

// set motion control loop to be used

//motor.controller = MotionControlType::torque;

//motor.controller = MotionControlType::velocity;

motor.controller = MotionControlType::angle;

/*

// foc current control parameters (Arduino UNO/Mega)

motor.PID_current_q.P = 5;

motor.PID_current_q.I = 300;

motor.PID_current_d.P = 5;

motor.PID_current_d.I = 300;

motor.LPF_current_q.Tf = 0.01;

motor.LPF_current_d.Tf = 0.01;

*/

/*

motor.PID_current_q.P = 2; //修改合适的PID参数以实现更好的效果

motor.PID_current_q.I = 800; //电机出现抖动、转速不稳定的情况,很有可能就是PID参数没调到合适的

motor.PID_current_d.P = 2;

motor.PID_current_d.I = 800;

motor.LPF_current_q.Tf = 0.002; // 1ms default

motor.LPF_current_d.Tf = 0.002; // 1ms default

*/

/*

// Q axis

// PID parameters - default

motor.PID_current_q.P = 5; // 3 - Arduino UNO/MEGA

motor.PID_current_q.I = 1000; // 300 - Arduino UNO/MEGA

motor.PID_current_q.D = 0;

motor.PID_current_q.limit = motor.voltage_limit;

// Low pass filtering - default

motor.LPF_current_q.Tf = 0.005; // 0.01 - Arduino UNO/MEGA

// D axis

// PID parameters - default

motor.PID_current_d.P = 5; // 3 - Arduino UNO/MEGA

motor.PID_current_d.I = 1000; // 300 - Arduino UNO/MEGA

motor.PID_current_d.D = 0;

motor.PID_current_d.limit = motor.voltage_limit;

// Low pass filtering - default

motor.LPF_current_d.Tf = 0.005;

*/

// Q axis

// PID parameters - default

motor.PID_current_q.P = .7; //.7 //.1 //2

motor.PID_current_q.I = 100; //300 // 10 //400

motor.PID_current_q.D = 0;

motor.PID_current_q.limit = motor.voltage_limit;

// Low pass filtering - default

motor.LPF_current_q.Tf = .001; // 0.01 - Arduino UNO/MEGA

// D axis

// PID parameters - default

motor.PID_current_d.P = .7; //.7 // .1

motor.PID_current_d.I = 100; //300 //10

motor.PID_current_d.D = 0;

motor.PID_current_d.limit = motor.voltage_limit;

// Low pass filtering - default

motor.LPF_current_d.Tf = .001;

// velocity PI controller parameters

motor.PID_velocity.P = .07; //.1

motor.PID_velocity.I = 1; //2

motor.PID_velocity.D = 0;

motor.LPF_velocity.Tf = 0.005f;

motor.P_angle.P = 20; //35

motor.velocity_limit = 300; //180

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add target command T

command.add('T', doTarget, "target angle");

command.add('C', currentLim, "current Limmit");

Serial.println(F("Motor ready."));

Serial.println(F("Set the target current using serial terminal:"));

_delay(1000);

flagTime = millis();

}

void loop() {

// main FOC algorithm function

motor.loopFOC();

// Motion control function

motor.move(target_angle);

// monitor angles & velocity at ~10 Hz

static unsigned long t_last = 0;

if (millis() - t_last > 150) {

t_last = millis();

/*

if (flag == 1 && millis() - flagTime > 500) {

target_angle = 0;

flag++;

flagTime = millis();

} else if (flag == 2 && millis() - flagTime > 500) {

target_angle = 10;

flag = 1;

flagTime = millis();

}

*/

//motor.current_limit = current_limit;

//motor.PID_velocity.limit = motor.current_limit;

Serial.print(" θ1:");

//Serial.print(motor.shaft_angle);

Serial.print(sensor.getAngle());

Serial.print("\tω1:");

Serial.print(motor.shaft_velocity, 3);

Serial.print("\tVq1:");

Serial.print(motor.voltage.q, 2);

Serial.print("\tA:");

Serial.print(current_sense.getDCCurrent()); // total current in Amps

Serial.print("\tAQ:");

Serial.println(motor.current.q); // Q current in Amps

// user communication

command.run();

}

}