Hi community,

I recently started to experiment with driving BLDC motors. My main intention is to put together a motorized leg for robot dog.

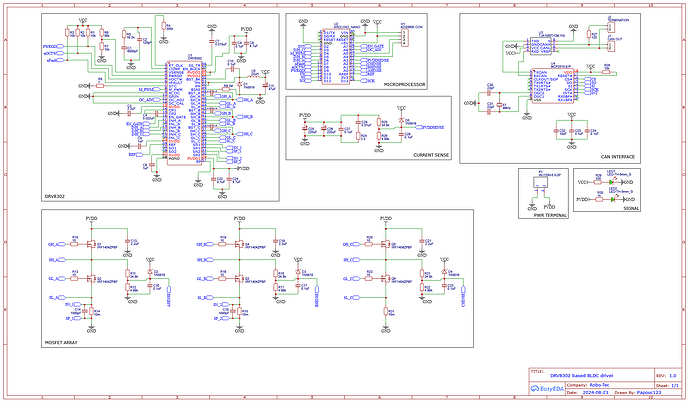

So I designed my custom driver board supporting SimpleFOC. I based it around DRV8302 from TI and Infenion’s IRF1404Z mosfets (schematic and PCB layout attached).

It works when i test it using driver.setPwm(A, B, C). Meaning voltage on all phases is correctly set. It also makes a small BLDC motor move, but eventually ends up burning it in like 3 or 4 seconds. The motor used for testing was A2212/13T (specsheet).

Could anyone please take a quick look if there are any obvious mistakes in my code / driver design?

Schematic:

Code:

#include <SimpleFOC.h>

// MANUALLY GROUNDED -> M_OC, GAIN, DC_CAL

// MANUALLY PULLED HIGH -> OC_ADJ (needes to be remade in final design)

// --- ENCODER ---

MagneticSensorI2C sensor(AS5600_I2C);

// --- DRIVER ---

#define INH_A 6

#define INH_B 5

#define INH_C 3

#define ENABLE A3

#define M_PWM 4

BLDCDriver3PWM driver(INH_A, INH_B, INH_C, ENABLE);

// --- CURRENT SENSING ---

// skip for now

// --- BLDC MOTOR ---

#define POLE_PARIS 7

#define KV 1000

BLDCMotor motor(POLE_PARIS, NOT_SET, KV);

void setup()

{

Serial.begin(115200);

sensor.init();

motor.linkSensor(&sensor);

// external driver setup

pinMode(M_PWM, OUTPUT);

digitalWrite(M_PWM, HIGH); // set 3-pwm mode

// set driver voltage to 12V

driver.voltage_power_supply = 20;

driver.voltage_limit = 12;

driver.init();

motor.linkDriver(&driver);

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

motor.controller = MotionControlType::velocity;

motor.useMonitoring(Serial);

motor.init();

motor.initFOC();

// set desired speed

motor.target = 1;

}

void loop()

{

motor.loopFOC();

// move at the desired speed

motor.move();

}

Thanks!!