Hi everyone,

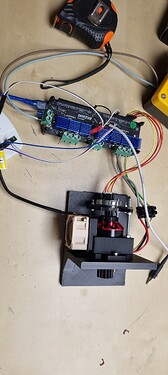

I’m starting to use SimpleFOC together with an ODrive board with a BLDC motor and an optical encoder.

Note that I’m brand new with SimpleFOC (but pretty experienced in programming, including all kind of microcontroller boards).

I got the code skeleton from the examples and this forum.

I checked the encoder standalone, which works fine. Then I checked the driver standalone, which works fine.

So far, so good.

Then I started with the very simple velocity_openloop mode, which works also fine: the motor rotate in the right direction, with the appropriate speed.

But I don’t succeed to do anything else. The velocity control (ie not openloop) does not work at all.

I tried to calibrate the PID’s as explained in this forum, without any success.

I digged a bit using the great simpleFOC-GUI, but no luck.

Any advice ?

My code :

#include <Arduino.h>

#include <SimpleFOC.h>

#include <SimpleFOCDrivers.h>

// https://github.com/simplefoc/Arduino-FOC/blob/master/examples/hardware_specific_examples/Odrive_examples/odrive_example_spi/odrive_example_spi.ino

// Odrive M0 motor pinout

#define M0_INH_A PA8

#define M0_INH_B PA9

#define M0_INH_C PA10

#define M0_INL_A PB13

#define M0_INL_B PB14

#define M0_INL_C PB15

// M0 currents

#define M0_IB PC0

#define M0_IC PC1

// Odrive M0 encoder pinout

#define M0_ENC_A PB4

#define M0_ENC_B PB5

#define M0_ENC_Z PC9

// M1 & M2 common enable pin

#define EN_GATE PB12

// SPI pinout

#define SPI3_SCL PC10

#define SPI3_MISO PC11

#define SPI3_MOSO PC12

Encoder encoder = Encoder(M0_ENC_A, M0_ENC_B, 5120, M0_ENC_Z);

/**

BLDCMotor class constructor

@param pp pole pairs number

@param R motor phase resistance - [Ohm]

@param KV motor KV rating (1/K_bemf) - rpm/V

@param L motor phase inductance - [H]

BLDCMotor(int pp, float R = NOT_SET, float KV = NOT_SET, float L = NOT_SET);

*/

BLDCMotor motor = BLDCMotor(14, NOT_SET , 600., NOT_SET);

// BLDCMotor motor = BLDCMotor(14);

BLDCDriver6PWM driver = BLDCDriver6PWM(M0_INH_A, M0_INL_A, M0_INH_B, M0_INL_B, M0_INH_C, M0_INL_C, EN_GATE);

// MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, M0_ENC_A);

// low side current sensing define

// 0.0005 Ohm resistor

// gain of 10x

// current sensing on B and C phases, phase A not connected

LowsideCurrentSense current_sense = LowsideCurrentSense(0.0005f, 10.0f, _NC, M0_IB, M0_IC);

Commander command = Commander(Serial);

void doMotor(char *cmd) { command.motor(&motor, cmd); }

void doA()

{

encoder.handleA();

}

void doB()

{

encoder.handleB();

}

void doIndex()

{

encoder.handleIndex();

}

/*

0 : sensor only

1 : driver only

*/

unsigned char what = -1;

void setup_sensor_only()

{

encoder.quadrature = Quadrature::ON;

encoder.pullup = Pullup::USE_INTERN;

encoder.init();

encoder.enableInterrupts(doA, doB, doIndex);

Serial.println("Encoder ready");

}

void setup_driver_only()

{

bool ret;

driver.pwm_frequency = 20000;

driver.voltage_power_supply = 15;

driver.voltage_limit = 15;

ret = driver.init();

driver.enable();

Serial.println("Driver ready");

}

void setup()

{

bool ret;

Serial.begin(115200);

if (what == 0)

{

setup_sensor_only();

return;

}

if (what == 1)

{

setup_driver_only();

return;

}

driver.pwm_frequency = 20000;

// power supply voltage [V]

driver.voltage_power_supply = 15;

// Max DC voltage allowed - default voltage_power_supply

driver.voltage_limit = 12;

// driver init

ret = driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

encoder.quadrature = Quadrature::ON;

encoder.pullup = Pullup::USE_INTERN;

encoder.init();

encoder.enableInterrupts(doA, doB, doIndex);

motor.linkSensor(&encoder);

// control loop type and torque mode

motor.torque_controller = TorqueControlType::voltage;

// resistance : 0.068 ohm

// motor.voltage_limit = motor.phase_resistance*motor.current_limit

// here : voltage_limit = 0.068 * current_limit(=.1)

//

motor.controller = MotionControlType::velocity_openloop;

// controller configuration based on the control type

// velocity PID controller parameters

// default P=0.5 I = 10 D =0

motor.PID_velocity.P = .05;

motor.PID_velocity.I = 1.;

motor.PID_velocity.D = 0.;

motor.LPF_velocity.Tf = 0.01;

// jerk control using voltage voltage ramp

// default value is 300 volts per sec ~ 0.3V per millisecond

motor.PID_velocity.output_ramp = 300;

// velocity low pass filtering

// default 5ms - try different values to see what is the best.

// the lower the less filtered

motor.LPF_velocity.Tf = 0.01;

// since the phase resistance is provided we set the current limit not voltage

// default 0.2

// motor.current_limit = 0.1; // Amps

// max voltage allowed for motion control

motor.voltage_limit = .6;

// alignment voltage limit

motor.voltage_sensor_align = 0.5;

// link the driver

current_sense.linkDriver(&driver);

// init the current sense

current_sense.init();

current_sense.skip_align = true;

motor.linkCurrentSense(¤t_sense);

command.add('M', doMotor, (char *)"motor");

// tell the motor to use the monitoring

motor.useMonitoring(Serial);

motor.monitor_downsample = 0; // disable monitor at first - optional

motor.init();

motor.initFOC();

delay(1000);

next_millis = HAL_GetTick() + 1000;

motor.move(.5);

}

void loop_sensor_only()

{

encoder.update();

float angle = encoder.getAngle();

float velocity = encoder.getVelocity();

long pulse = encoder.getPulse();

// display the angle and the angular velocity to the terminal

Serial.print("A:");

Serial.print(angle);

Serial.print("\t");

Serial.print("P:");

Serial.print(pulse);

Serial.print("\t");

Serial.println(velocity);

}

void loop_driver_only()

{

// setting pwm (A: 3V, B: 1V, C: 5V)

driver.setPwm(3, 1, 5);

}

void loop()

{

// Read the measured angle

// float angle = as5047p.readAngle();

if (what == 0)

{

loop_sensor_only();

return;

}

if (what == 1)

{

loop_driver_only();

return;

}

// encoder.update();

// foc loop

motor.loopFOC();

// motion control

motor.move();

// monitoring

motor.monitor();

// real-time commander calls

command.run();

/*

my_angle = encoder.getSensorAngle();

uint32_t now = HAL_GetTick();

if (next_millis && (now >= next_millis))

{

next_millis = now + 1000;

}

*/

}