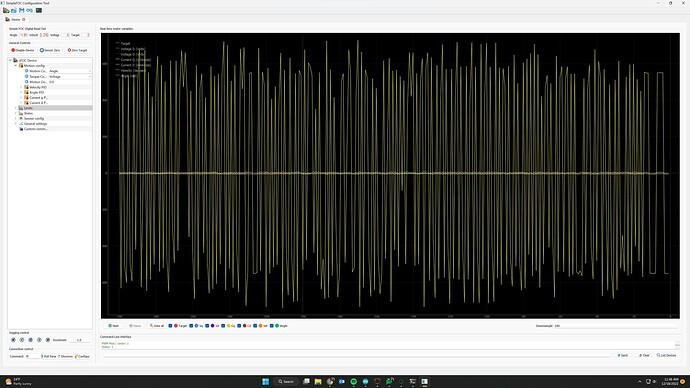

Been playing with it today. Ran the code, the reaction wheel jitters back and forth. sometimes it damps out and stops, other times I can add a bit of friction with my finger and stop it. I never tries to spin in such a way that might result in swinging the pendulum. I add the code and installed SimpleFOCStudio and below is a trace it made.

While the motor was stationary and I was reading…maybe an hour? I noticed what looked like a motor mounting screw might have backed out but no! The motor had gotten quite HOT and was melting the 3D printer material. I don’t think I “smoked” anything but wow.

attached is my current code, most from your examples and a photo of the Studio output. Since I get stable and predictable readings from both encoders - at this point I don’t think they are causing problems. I think it is a matter of tuning but I have no idea where or how to start. I see posts that suggest PID adjustments but is there no logical approach to this? Simply changing numbers at random does not seem productive.

I feel like I need to reload the position_motion_control script and do any tuning there. Seems that must work correctly before the pendulum program could.

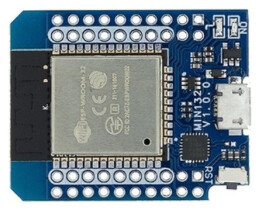

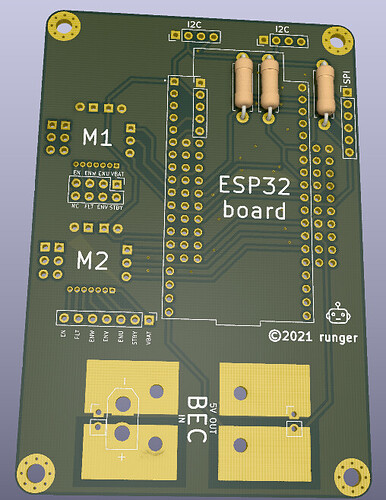

Here is my code, it is running on an SP32 WROOM-32 Wemos D1 LOLIN32 WIFI+BT 2.4GHz Dual Mode Developer Board:

#include <SimpleFOC.h>

#define sign(x) ((x) < 0 ? -1 : ((x) > 0 ? 1 : 0))

MagneticSensorI2C sensor = MagneticSensorI2C(AS5600_I2C);

MagneticSensorI2C pendulum = MagneticSensorI2C(AS5600_I2C);

// BLDC motor init

BLDCMotor motor = BLDCMotor(11,10.9,42);

// define BLDC driver

BLDCDriver3PWM driver = BLDCDriver3PWM(16,17,18,19);

// include commander interface

Commander command = Commander(Serial);

void doMotor(char* cmd) { command.motor(&motor, cmd); }

void setup() {

// initialize motor encoder hardware

sensor.init();

motor.linkSensor(&sensor);

// driver config

driver.voltage_power_supply = 14.8;

driver.init();

// init the pendulum encoder

Wire1.begin(33, 32, (uint32_t)400000); //Keshka put sda on pin 33 and scl on 32 for second sensor

pendulum.init(&Wire1);

//PciManager.registerListener(&listenerPA);

//PciManager.registerListener(&listenerPB);

// set control loop type to be used

motor.torque_controller = TorqueControlType::voltage;

motor.controller = MotionControlType::torque;

// link the motor to the encoder

motor.linkSensor(&sensor);

// link the motor to the driver

motor.linkDriver(&driver);

// initialize motor

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 14.8;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// choose FOC modulation (optional)

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set motion control loop to be used

motor.controller = MotionControlType::angle;

// contoller configuration

// default parameters in defaults.h

// velocity PI controller parameters

motor.PID_velocity.P = 0.2f;

motor.PID_velocity.I = 20;

motor.PID_velocity.D = 0;

// maximal voltage to be set to the motor

motor.voltage_limit = 6;

// velocity low pass filtering time constant

// the lower the less filtered

motor.LPF_velocity.Tf = 0.01f;

// angle P controller

motor.P_angle.P = 20;

// maximal velocity of the position control

motor.velocity_limit = 5; //was 20

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align encoder and start FOC

motor.initFOC();

// add the motor to the commander interface

// The letter (here 'M') you will provide to the SimpleFOCStudio

command.add('M',doMotor,"motor");

// tell the motor to use the monitoring

motor.useMonitoring(Serial);

motor.monitor_downsample = 0; // disable monitor at first - optional

}

// loop down-sampling counter

long loop_count = 0;

void loop() {

// ~1ms

motor.loopFOC();

// pendulum sensor read

pendulum.update();

// control loop each ~25ms

if(loop_count++ > 25){

// calculate the pendulum angle

float pendulum_angle = constrainAngle(pendulum.getAngle() + _PI);

float target_voltage;

if( abs(pendulum_angle) < 0.5 ) // if angle small enough stabilize

target_voltage = controllerLQR(pendulum_angle, pendulum.getVelocity(), motor.shaft_velocity);

else // else do swing-up

// sets 40% of the maximal voltage to the motor in order to swing up

target_voltage = -_sign(pendulum.getVelocity())*driver.voltage_power_supply*0.4;

// set the target voltage to the motor

motor.move(target_voltage);

// restart the counter

loop_count=0;

}

// real-time monitoring calls

motor.monitor();

// real-time commander calls

command.run();

}

// function constraining the angle in between -pi and pi, in degrees -180 and 180

float constrainAngle(float x){

x = fmod(x + _PI, _2PI);

if (x < 0)

x += _2PI;

return x - _PI;

}

// LQR stabilization controller functions

// calculating the voltage that needs to be set to the motor in order to stabilize the pendulum

float controllerLQR(float p_angle, float p_vel, float m_vel){

// if angle controllable

// calculate the control law

// LQR controller u = k*x

// - k = [40, 7, 0.3]

// - x = [pendulum angle, pendulum velocity, motor velocity]'

float u = 40*p_angle + 7*p_vel + 0.3*m_vel;

// limit the voltage set to the motor

if(abs(u) > driver.voltage_power_supply*0.7) u = sign(u)*driver.voltage_power_supply*0.7;

return u;

}

Here is the trace: