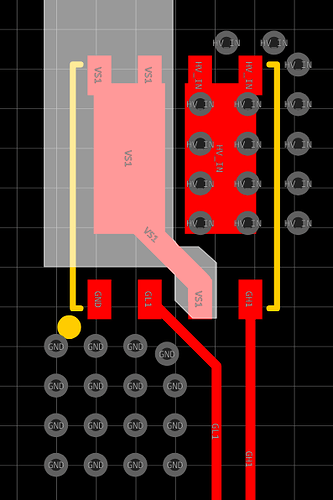

I wanna make something similar to the dengFOC/dualFOC driver board, but much more compact, hopefully cheaper, and with an integrated g473 mcu. I’d probably use it to drive iPower 2804 or cubemars gl-30 motors. The board will mainly be used as a smart knob and to drive tendons in a robot hand. I may also use it as a generic BLDC motor driver for future projects. I plan to put a JST-SH footprint beside the magnetic encoder that breaks out the communication lines so that the motors may not necessarily be mounted together directly on the back of the PCB.

MCU: STM32G473

Gate driver: FD6288Q

CSA: TPA132A2 or INA240A2

Magnetic Encoder: MT6701

I was looking at fets and found some dual channel varieties: https://www.lcsc.com/product-detail/C53069588.html?s_z=n_XRS60J04F The RDSon is not bad, but will it complicate layout? It seems like most designs use two separate fets, is it for legacy, thermal, cost, and/or layout reasons?

Probably will use 10mOhm for current sensing and 2 100uF bulk caps per motor

Would appreciate some buck/ldo recommendations, as well as some pointers on where I need to put things like ESD/TVS diodes and snubbers. Was planning to use a REF3033AIDBZR for voltage reference, but haven’t put much thought into it.

Is this hardware overkill for a 2804? should I just slap two microsporas together and call it a day?Also would be interested in how big of a motor this stuff could drive, assuming I route it competently… as much of a learning experience as it will be a practical board, so advice about making my life easier would be appreciated. I recently fabbed @VIPQualityPost ‘s Lemon Pepper Stepper on my openPnP machine, but that should be a thread of it’s own.