Hello, Thank you for SimpleFOC!

I have been heavily involved with another open source project called OpenHD (primarily as a tester as i’m really not good at programming)…

But, I have a lot of interest in a micro 3-axis gimbal for fpv drone usage based on the Storm32 platform (which I’ve seen some other threads on here about).

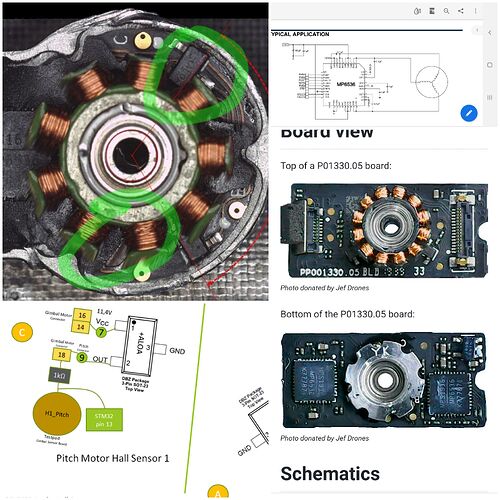

I have picked up some stock DJI Mavic style gimbals and looked into the inner-workings and, learned that most of the models utilize LINEAR HALL sensors with the designs. I’ve attached some pictures below…

![]() There are one TWO- TI DRV5053 LINEAR HALLS ON EACH AXIS… (I assume because the gimbals do not move more than 45° on each axis roughly)??

There are one TWO- TI DRV5053 LINEAR HALLS ON EACH AXIS… (I assume because the gimbals do not move more than 45° on each axis roughly)??

Here is a YouTube video showing how they work…

My thinking was that with a company as big as dji, there must be a reason they’re utilizing this kind of Hall sensor on the really small brushless motors?

My primary objective is to have the ability to drive the three axis nice small stock gimbals as a standalone drone gimbal or laser pointer… But, all open source solutions appear to opt for the on access magnetic sensors…

I would appreciate any thoughts or feedback…