Hi!

I got a small 3 wire BLDC motor (no Hall sensor) from an auction from used dental parts. Specifically it’s a Dental Electric Brushless Micromotor.

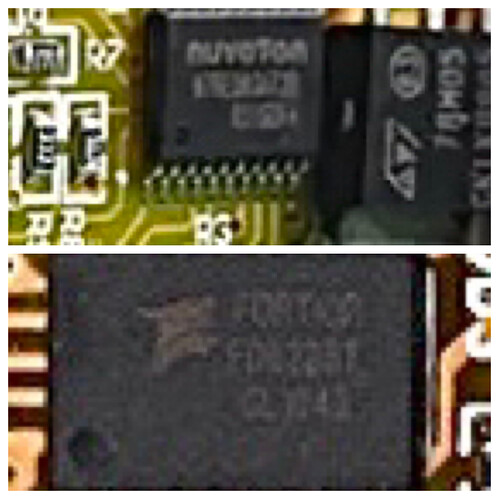

I bought just the motor and cable. But I have another one complete set just like it working and installed. (Driver, supply and micromotor)

I’d like to know it with FOC hardware/software, I could get it this extra motor I bought running back running again, by creating a new driver for it. I know I could search for an used original driver, but for the fun of the project, I’d like to create a new driver for it myself. I’ll use it as small driller for my hobby projects.

What I know about it is:

The BLDC motor itself have 5cm length, 2 cm diameter

The power supply for the original driver is 48V DC, 1.25A (50W-63W). So I guess the motor runs at max 48V DC, but not sure about it. Could be less. Is there a way to measure it? I could measure it in my other working unit, but just don’t know where in the PCB (or motor) to measure it.

The motor itself has 2.5 ohms of resistance between each two poles, so it sits between the gimbal motors and high power BLDC motors. It seems to have a max torque allowed in it’s original driver/supply of 3N.cm

Calculating the max current would give 19.2A (48V/2.5), which I think it’s too much… Is there a way to measure it also? I could measure in the other working unit if needed.

It runs at 40.000RPM max direct drive, with no gears.

It doesn’t have hall sensor wires, nor encoders. But It’s original controller can make it reverse rotation if needed.

I don’t need to know the position of the motor, nor the perfect exact speed. It’s basically just’s a driller that goes from 0 to 40.000 RPM, keeping it’s torque.

So would it be possible to create a new driver to run this type of sensorless motor? Can someone point me which type of hardware driver (from the suported driver boards list) would fit in this description?

If extra details are needed, fell free to ask!

Thanks for the help!!!