Hi,

I am trying to position control 8 N20 DC motors with encoders using SimpleDCMotor library using STM32F722ZE.

I am using Generic sensor implementation to calculate angle. The position control works for positive angles only. i.e :

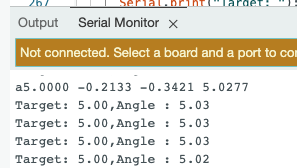

- If I ask the motor to go to 5rad with commander input as a5 it works.

- Then inputing a2 also works, moving the motor back

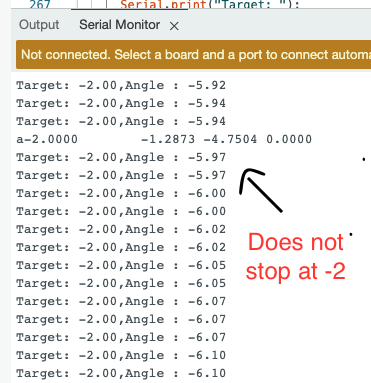

- If I then input a-2, then motor keeps rotating forever once it goes below 0rad.

You can see the serial monitor screenshots below. Upon noticing, what I see is, both encoder value, angle value are correct but the actual position reading(4th value) from Monitor does not go below 0rad. If i manually rotate the motor as well, the angle reading is fine but monitor reading is not.

-

Moving to a5 (5 rad, motor1) stops at 5 rad

-

Moving to a2, stops at 2.

-

Moving to a-2 , does not stop at all

I remember, this code worked when I tested in Esp32 few months back (not sure of library versions).

Current Library versions installed are latest:

SimpleFoc: 2.3.4

SimpleDCMotor:1.0.3

SimpleFOCDrivers: 1.0.8

I am not good at coding embedded systems, please see if any mistakes in my Code below:

#include <Arduino.h>

#include "SimpleFOC.h"

#include "SimpleFOCDrivers.h"

#include "SimpleDCMotor.h"

#include <vector>

#include <sstream>

#include <iterator>

using namespace std;

const int numMotors = 1;

const int numMotorsToMove = 1;

struct MotorInfo {

int encoderPinE1;

int encoderPinE2;

int driverPin1;

int driverPin2;

DCDriver2PWM driver;

volatile int lastEncoded;

volatile long encoderValue;

volatile float angle;

DCMotor motor;

GenericSensor sensor;

MotorInfo()

: encoderPinE1(0), encoderPinE2(0), driverPin1(0), driverPin2(0), driver(DCDriver2PWM(0, 0)), lastEncoded(0), encoderValue(0), angle(0.0f), motor(), sensor([](){ return 0.0f; }) {}

};

MotorInfo motors[numMotors];

Commander commander = Commander(Serial);

#define DEFINE_SENSOR_CALLBACK(idx) \

float readSensor##idx() { return motors[idx].angle; }

#define DEFINE_COMMANDER_CALLBACK(idx) \

void onMotor##idx(char* cmd) { commander.motor(&motors[idx].motor, cmd); }

#define DEFINE_UPDATE_ENCODER_CALLBACK(idx) \

void updateEncoder##idx() { updateEncoder(idx); }

DEFINE_SENSOR_CALLBACK(0)

DEFINE_SENSOR_CALLBACK(1)

DEFINE_SENSOR_CALLBACK(2)

DEFINE_SENSOR_CALLBACK(3)

DEFINE_SENSOR_CALLBACK(4)

DEFINE_SENSOR_CALLBACK(5)

DEFINE_SENSOR_CALLBACK(6)

DEFINE_SENSOR_CALLBACK(7)

DEFINE_COMMANDER_CALLBACK(0)

DEFINE_COMMANDER_CALLBACK(1)

DEFINE_COMMANDER_CALLBACK(2)

DEFINE_COMMANDER_CALLBACK(3)

DEFINE_COMMANDER_CALLBACK(4)

DEFINE_COMMANDER_CALLBACK(5)

DEFINE_COMMANDER_CALLBACK(6)

DEFINE_COMMANDER_CALLBACK(7)

DEFINE_UPDATE_ENCODER_CALLBACK(0)

DEFINE_UPDATE_ENCODER_CALLBACK(1)

DEFINE_UPDATE_ENCODER_CALLBACK(2)

DEFINE_UPDATE_ENCODER_CALLBACK(3)

DEFINE_UPDATE_ENCODER_CALLBACK(4)

DEFINE_UPDATE_ENCODER_CALLBACK(5)

DEFINE_UPDATE_ENCODER_CALLBACK(6)

DEFINE_UPDATE_ENCODER_CALLBACK(7)

typedef float (*FnPtr)();

const FnPtr sensorCallBackArrays[]{

readSensor0,readSensor1,readSensor2,readSensor3,

readSensor4,readSensor5,readSensor6,readSensor7

};

typedef void (*CommanderFnPtr)(char* cmd);

const CommanderFnPtr commanderFunctionArrays[]{

onMotor0, onMotor1, onMotor2, onMotor3,

onMotor4, onMotor5, onMotor6, onMotor7

};

typedef void (*InterruptFnPtr)();

const InterruptFnPtr interruptFunctionArrays[]{

updateEncoder0, updateEncoder1,updateEncoder2,updateEncoder3,

updateEncoder4, updateEncoder5,updateEncoder6,updateEncoder7

};

// Define encoder and motor pins for each motor

const int encoderPins[][8] = {

{PC2, PC1}, // PF15, PE13

{PC0, PC3}, //

{PD4, PD5},

{PD6, PD7},

{PG8, PG9},

{PG10,PG11},

{PG12, PG13},

{PG14, PG15}

};

const int driverPins[][8] = {

{PA9,PA8}, // TIM1-CH1, TIM1-CH2

{PA11,PA10}, // TIM1-CH3, TIM1-CH4

{PA5,PB3}, // TIM2-CH1, TIM2-CH2

{PB11,PB10}, // TIM2-CH3, TIM2-CH4

{PA7,PA6}, // TIM3-CH1, TIM3-CH2

{PC8,PC9}, // TIM3-CH3, TIM3-CH4

{PD12,PD13}, // TIM4-CH1, TIM4-CH2

{PD14,PD15}, // TIM4-CH3, TIM4-CH4

// {PA0,PA1}, // TIM5-CH1, TIM5-CH2

// {PA2,PA3}, // TIM5-CH3, TIM5-CH4

// {PC6,PC7}, // TIM8-CH1, TIM8-CH2

// {PC8,PC9}, // TIM8-CH3, TIM8-CH4

// {PE5,PE6}, // TIM9-CH1, TIM9-CH2

// {PB14,PB15}, // TIM12-CH1, TIM12-CH2

};

void updateEncoder(int motorIndex) {

int MSB = digitalRead(motors[motorIndex].encoderPinE1);

int LSB = digitalRead(motors[motorIndex].encoderPinE2);

int encoded = (MSB << 1) | LSB;

int sum = (motors[motorIndex].lastEncoded << 2) | encoded;

if (sum == 0b1101 || sum == 0b0100 || sum == 0b0010 || sum == 0b1011) motors[motorIndex].encoderValue--;

if (sum == 0b1110 || sum == 0b0111 || sum == 0b0001 || sum == 0b1000) motors[motorIndex].encoderValue++;

motors[motorIndex].lastEncoded = encoded;

motors[motorIndex].angle = (motors[motorIndex].encoderValue * 6.28319) /9048.0f;

}

void initMotor(int motorIndex, float P, float I, float D) {

motors[motorIndex].driver = DCDriver2PWM(motors[motorIndex].driverPin1, motors[motorIndex].driverPin2);

motors[motorIndex].driver.voltage_power_supply = 12.0f;

motors[motorIndex].driver.voltage_limit = 12.0f;

motors[motorIndex].driver.pwm_frequency = 100;

motors[motorIndex].driver.init();

motors[motorIndex].sensor = GenericSensor(sensorCallBackArrays[motorIndex]);

motors[motorIndex].sensor.init();

motors[motorIndex].motor.linkDriver(&(motors[motorIndex].driver));

motors[motorIndex].motor.linkSensor(&(motors[motorIndex].sensor));

motors[motorIndex].motor.voltage_limit = 12.0f;

// motors[motorIndex].motor.velocity_limit = 20.0f;

// if(motorIndex!=2)

motors[motorIndex].motor.velocity_limit = 6.0f;

motors[motorIndex].motor.controller = MotionControlType::angle;

motors[motorIndex].motor.torque_controller = TorqueControlType::voltage;

motors[motorIndex].motor.init();

motors[motorIndex].motor.PID_velocity.P = P;

motors[motorIndex].motor.PID_velocity.I = I;

motors[motorIndex].motor.PID_velocity.D = D;

motors[motorIndex].motor.PID_velocity.output_ramp = 400.0f;

motors[motorIndex].motor.LPF_velocity.Tf = 0.001f;

motors[motorIndex].motor.P_angle.P = 22.5f;

motors[motorIndex].motor.enable();

motors[motorIndex].motor.sensor_direction = Direction::CW;

motors[motorIndex].motor.useMonitoring(Serial);

//motors[motorIndex].motor.monitor_downsample = 500;

motors[motorIndex].motor.monitor_start_char = 'a'+motorIndex;

}

void setup() {

while(!Serial);

Serial.begin(115200);

Serial.print("Max Timers:");

Serial.println(SIMPLEFOC_STM32_MAX_PINTIMERSUSED);

for (int i = 0; i < numMotors; i++) {

// Serial.println("motor init");

motors[i].encoderPinE1 = encoderPins[i][0];

motors[i].encoderPinE2 = encoderPins[i][1];

motors[i].driverPin1 = driverPins[i][0];

motors[i].driverPin2 = driverPins[i][1];

motors[i].lastEncoded = 0;

motors[i].encoderValue = 0;

// motors[i].angle = 0.0f;

// motors[i].motor.target=0.0f;

// Serial.println("motor set");

pinMode(motors[i].encoderPinE1, INPUT_PULLUP);

pinMode(motors[i].encoderPinE2, INPUT_PULLUP);

pinMode(motors[i].driverPin1, OUTPUT);

pinMode(motors[i].driverPin2, OUTPUT);

// Serial.println("Pinmode set");

digitalWrite(motors[i].encoderPinE1, HIGH);

digitalWrite(motors[i].encoderPinE2, HIGH);

attachInterrupt(digitalPinToInterrupt(motors[i].encoderPinE1), interruptFunctionArrays[i], CHANGE);

attachInterrupt(digitalPinToInterrupt(motors[i].encoderPinE2), interruptFunctionArrays[i], CHANGE);

float p = 1.0f;

// if(i!=0&&i!=1){

// p=4.2f;

// }

initMotor(i, p, 0.02f, 0.001f);

commander.add('a' + i, commanderFunctionArrays[i], "DC motor ");

}

Serial.println("Initialization complete.");

}

template <typename Out>

void split(const std::string &s, char delim, Out result) {

std::istringstream iss(s);

std::string item;

while (std::getline(iss, item, delim)) {

*result++ = item;

}

}

vector<string> split(const string &s, char delim) {

vector<string> elems;

split(s, delim, back_inserter(elems));

return elems;

}

void parseSerialInput(string input) {

vector<string> motorCommands = split(input, ',');

for (string command : motorCommands) {

// Serial.println(const_cast<char*>(command.c_str()));

commander.run(const_cast<char*>(command.c_str()));

}

}

void loop() {

if (Serial.available() > 0) {

string input = Serial.readStringUntil('\n').c_str();

parseSerialInput(input);

}

for (int i = 0; i < numMotorsToMove; i++) {

if(i==0){

motors[i].motor.move();

motors[i].motor.monitor();

Serial.print(motors[0].motor.target);

Serial.print(": ");

Serial.println(motors[i].angle);

}

}

}