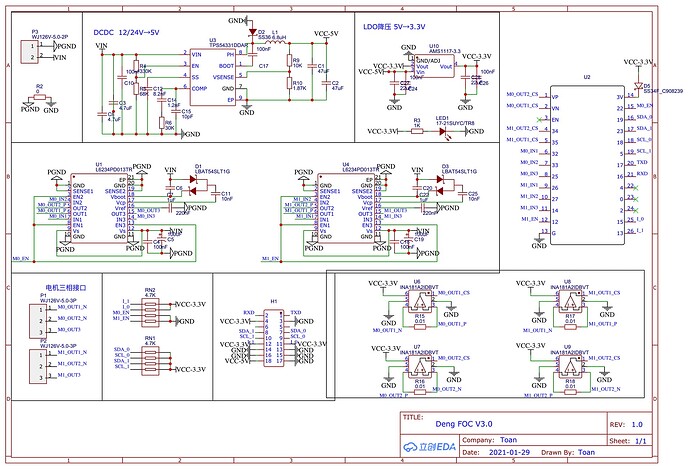

issues reading the total current sent to the motor. My set up consists of a GM3506 Gimbal Motor (5.6ohms) a MKS Dual FOC board and an esp32 dev board. According to the schematics the MKS board has a 0.01ohm resistor and a op amp gain of 50. I set that up using InlineCurrentSense(0.01f, 50.0f, 35, 34); but when I call getDCCurrent() it is inaccurate. From following tests I noted that the power supply current was 0.27amps while the getDCCurrent() read about 1.2 amps. I also tried at a current of 1.10 amps from the power supply and the getDCCurrent() read about 2.4 amps. So it’s consistently reading higher than the real current. I cant figure out what is going on. Ive tried messing with th eInlineCurr entSense(0.01f, 50.0f, 35, 34); values just in case and also changing the the gain_b and gain_a to -1. I also switched out the esp32 incase its ADC was the problem but to no avail. Please I would appreciate any help with this.

Notes: using Simple FOC library 2.3.2

code for reference:

#include <Arduino.h>

#include <SimpleFOC.h>

MagneticSensorSPI sensor2 = MagneticSensorSPI(AS5147_SPI, 15);

BLDCMotor motor2 = BLDCMotor(11);

BLDCDriver3PWM driver2 = BLDCDriver3PWM(26, 27, 14, 12); //MKS esp32

InlineCurrentSense current_sense2 = InlineCurrentSense(0.01f, 50.0f, 35, 34); //MKS dual foc esp32

// Motor and Actuator 2 parameters

float target_angle_m2 = 0; // Radians - motor

float target_angle_a2 = 0; // Radians - actuator

float angle_a2; // Radians

float velocity_a2; // Radians per second

float angle_offset_m2 = 0; // Radians

float joint_stop_a2 = 15 * (PI / 180.0); // Radians - Joint stop angle from zero

unsigned long homingTime;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) {

command.scalar(&target_angle_a2, cmd);

}

void Homing() {

bool homing_m2 = true; //when homing true, false when home has been found

homingTime = millis();

target_angle_m2 = motor2.shaft_angle;

motor2.move(target_angle_m2);

while (homing_m2) {

motor2.loopFOC();

motor2.move(target_angle_m2);

if (millis() - homingTime > 50) {

//Motor 2 Homing

if (abs(motor2.voltage.q) < 1.5 && homing_m2) {

target_angle_m2 -= .3;

motor2.move(target_angle_m2);

} else if (homing_m2) {

angle_offset_m2 = motor2.shaft_angle;

homing_m2 = false;

target_angle_m2 = .5 + angle_offset_m2;

motor2.loopFOC();

Serial.print("Homing Found M2");

Serial.print(angle_offset_m2);

Serial.print(" ");

}

Serial.print(" M2 Tθ:");

Serial.print(target_angle_m2);

Serial.print(" V:");

Serial.println(motor2.voltage.q);

//Serial.print(" A:");

//Serial.println(current_sense1.getDCCurrent()); // total current in Amps

homingTime = millis();

}

}

}

void setup() {

// use monitoring with serial

Serial.begin(115200);

// enable more verbose output for debugging

// comment out if not needed

SimpleFOCDebug::enable(&Serial);

// initialise magnetic sensor hardware

sensor2.init();

// link the motor to the sensor

motor2.linkSensor(&sensor2);

driver2.pwm_frequency = 20000;

// driver config

// power supply voltage [V]

driver2.voltage_power_supply = 24;

driver2.voltage_limit = 24; // max voltage to motor

driver2.init();

// link the motor and the driver

motor2.linkDriver(&driver2);

// link current sense and the driver

current_sense2.linkDriver(&driver2);

// current sense init hardware

current_sense2.init();

//current_sense2.gain_b *= -1;

//current_sense2.gain_a *= -1;

// link the current sense to the motor

motor2.linkCurrentSense(¤t_sense2);

// choose FOC modulation (optional)

motor2.foc_modulation = FOCModulationType::SpaceVectorPWM;

//motor.torque_controller = TorqueControlType::foc_current;

//motor.current_limit = 1; // Amp limit

// set motion control loop to be used

motor2.controller = MotionControlType::angle;

// contoller configuration

// default parameters in defaults.h

// velocity PI controller parameters

motor2.PID_velocity.P = .1;

motor2.PID_velocity.I = 2;

motor2.PID_velocity.D = 0;

// maximal voltage to be set to the motor

motor2.voltage_limit = 12; //8

// velocity low pass filtering time constant

motor2.LPF_velocity.Tf = 0.01f;

// angle P controller

motor2.P_angle.P = 10;

// maximal velocity of the position control

motor2.velocity_limit = 190;

// comment out if not needed

motor2.useMonitoring(Serial);

// initialize motor

motor2.init();

// align sensor and start FOC;

motor2.initFOC();

// add target command T

command.add('T', doTarget, "target angle");

Serial.println(F("Motor ready."));

Serial.println(F("Set the target angle using serial terminal:"));

_delay(1000);

// Homing %%%%%%%%%%%%%%%%%%%%%%

Homing();

target_angle_a2 = 0;

}

void loop() {

//PhaseCurrent_s currents = current_sense.getPhaseCurrents();

// main FOC algorithm function

// the faster you run this function the better

motor2.loopFOC();

target_angle_m2 = target_angle_a2 * 9;

motor2.move(target_angle_m2 + angle_offset_m2 + (joint_stop_a2 * 9));

// monitor angles & velocity at ~10 Hz

static unsigned long t_last = 0;

if (millis() - t_last > 150) {

t_last = millis();

angle_a2 = (motor2.shaft_angle - angle_offset_m2) / 9 - joint_stop_a2;

velocity_a2 = motor2.shaft_velocity / 9;

// Actuator Stats:

Serial.print(" θ2:");

Serial.print(angle_a2, 3);

Serial.print(" ω2:");

Serial.print(velocity_a2, 3);

Serial.print(" Vq2:");

Serial.print(motor2.voltage.q, 2);

Serial.print(" A2:");

Serial.print(current_sense2.getDCCurrent()); // total current in Amps

Serial.println();

// user communication

command.run();

}

}