Hello C++ Experts

It took me a few days to get my setup working with the example files. But the setup is done.

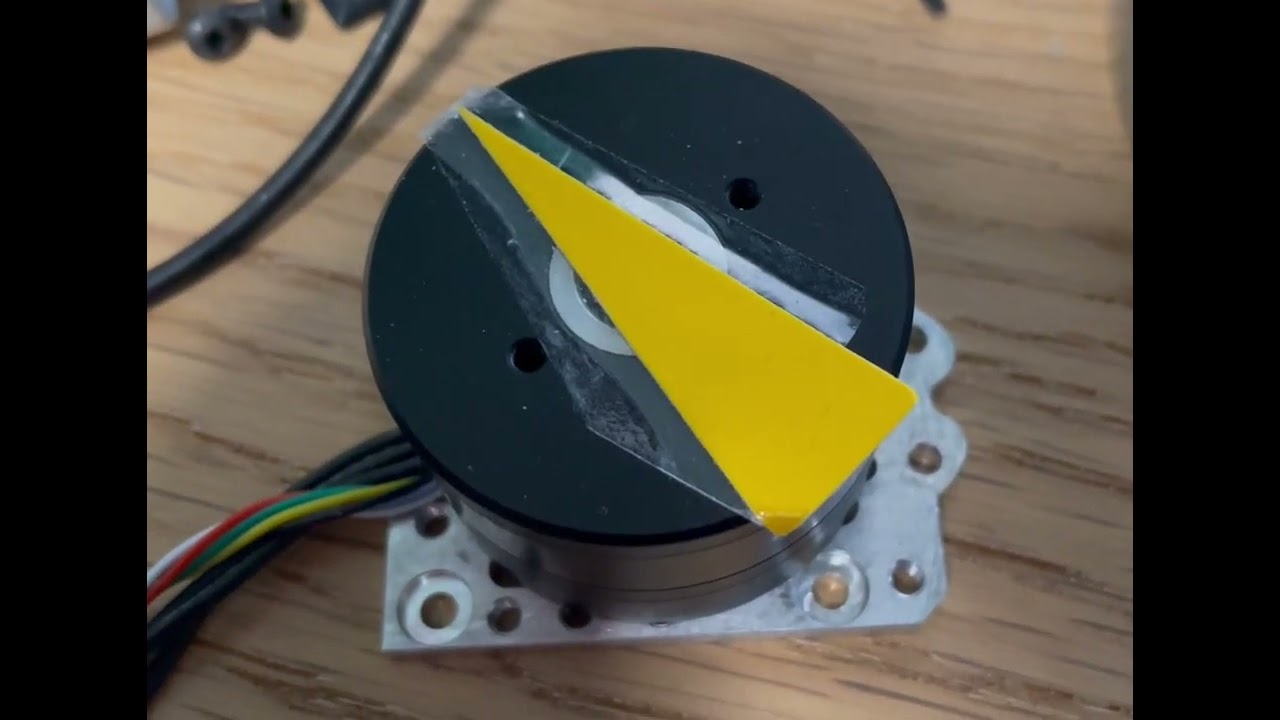

Im using one iPower Motor GM3506 with AS5048 encoder on a Arduino Nano ESP32 and SimpleFOC Mini. With one 12V power supply for the Arduino and FOC mini.

Pins in the sketch are mixed mode. SPI and Motor EN pin are configured as Arduino pins and IN1, 2 and 3 as ESP32 GPIO Pins.

I will 3D Print a mount for the motor and a mount for the webcam to the motor.

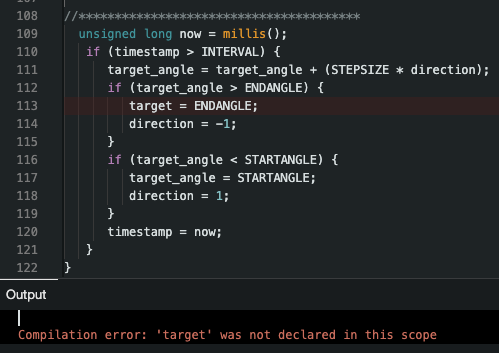

But my problem is C++ ![]() I can make a LED blink on the Arduino, that’s about is.

I can make a LED blink on the Arduino, that’s about is. ![]()

And that is where I need help please!!!

I think the angle Sketch works the best for what I would like to do.

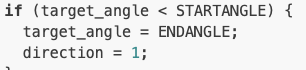

Step 1. Get the motor to move 270 degrees in a loop, so move from 0 135 degrees then -135 degrees and back 135 degrees ec.

It will have to move slow, so that the webcam can pickup the image, but I would like to have maximum torque on the motor. Can anyone please help me with this if and if then if whahahaha

Step 2. But this has no prior, I would like to add Bluetooth and be able to change the angle and speed of the motor movement, without having to take it down and load new code.

My sketch im testing with at the moment.

#include <SimpleFOC.h>

// magnetic sensor instance - SPI

MagneticSensorSPI sensor = MagneticSensorSPI(AS5048_SPI, 10); //(CS - Arduino Port)

// BLDCMotor(pole pair number, phase resistance [Ohms], KV rating [rpm/V])

BLDCMotor motor = BLDCMotor(11); //5.8ohm

BLDCDriver3PWM driver = BLDCDriver3PWM(18, 8, 9, 8); //(IN1 - GPIO Port, IN2 - GPIO Port, IN3 - GPIO Port, EN - Arduino Port)

// angle set point variable

float target_angle = 0;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&target_angle, cmd); }

void setup() {

// initialise magnetic sensor hardware

sensor.init();

// link the motor to the sensor

motor.linkSensor(&sensor);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// choose FOC modulation (optional)

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set motion control loop to be used

motor.controller = MotionControlType::angle;

// contoller configuration

// default parameters in defaults.h

// velocity PI controller parameters

motor.PID_velocity.P = 0.2f;

motor.PID_velocity.I = 20;

motor.PID_velocity.D = 0;

// maximal voltage to be set to the motor

motor.voltage_limit = 6;

// velocity low pass filtering time constant

// the lower the less filtered

motor.LPF_velocity.Tf = 0.01f;

// angle P controller

motor.P_angle.P = 20;

// maximal velocity of the position control

motor.velocity_limit = 2;

// use monitoring with serial

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add target command T

command.add('T', doTarget, "target angle");

Serial.println(F("Motor ready."));

Serial.println(F("Set the target angle using serial terminal:"));

_delay(1000);

}

void loop() {

// main FOC algorithm function

// the faster you run this function the better

// Arduino UNO loop ~1kHz

// Bluepill loop ~10kHz

motor.loopFOC();

// Motion control function

// velocity, position or voltage (defined in motor.controller)

// this function can be run at much lower frequency than loopFOC() function

// You can also use motor.move() and set the motor.target in the code

motor.move(target_angle);

// function intended to be used with serial plotter to monitor motor variables

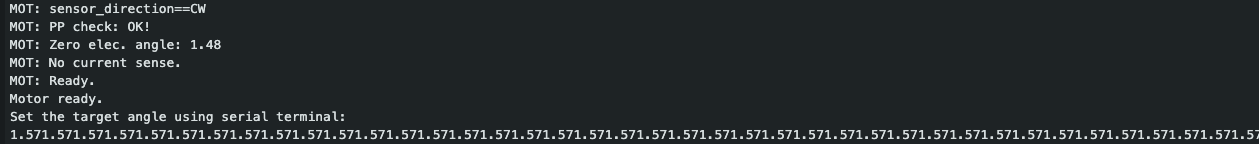

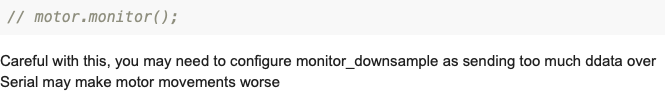

// significantly slowing the execution down!!!!

// motor.monitor();

// user communication

command.run();

}

Im thankful for any help or feedback!