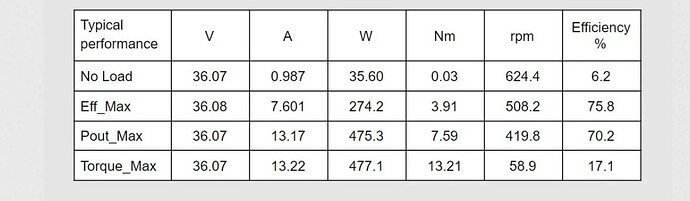

I’d like some help to understand why I am seeing such a low torque output with my Hoverboard motor, in theory capable of achieving 10-15 Nm.

Hardware used: ESP32, DRV8302, Hoverboard motor, AS5048A encoder.

Tested max torque with these two setups:

-

Using DC adjustable power supply at 24V, max current limit set to 9A. Result: Current limit reached on power supply, max torque measured: 3-4 Nm

-

Using Hoverboard battery 36V. Result: motor.voltage_limit is reached, measured torque is a bit smaller than scenario 1, around 3 Nm

Any help/ideas to try would be appreciated!!

Below is the relevant part of my code

#include <Arduino.h>

#include <SimpleFOC.h>

// DRV8302 pins connections

// don't forget to connect the common ground pin

#define INH_A_1 14

#define INH_B_1 12

#define INH_C_1 13

#define EN_GATE_1 27

#define M_PWM 32

#define M_OC 25

#define OC_ADJ 26

#define OC_GAIN 33

#define IOUTA 36

#define IOUTB 39

#define IOUTC 34

// Define the SPI pins for VSPI

#define CS_PIN_ENCODER 5

// motor instance

BLDCMotor motor = BLDCMotor(15);

// driver instance

BLDCDriver3PWM driver = BLDCDriver3PWM(INH_A_1, INH_B_1, INH_C_1, EN_GATE_1);

// DRV8302 board has 0.005Ohm shunt resistors and the gain of 12.22 V/V

LowsideCurrentSense currentSense = LowsideCurrentSense(0.005f, 12.22f, IOUTA, IOUTB, IOUTC);

// Create sensor objects

MagneticSensorSPI sensor = MagneticSensorSPI(CS_PIN_ENCODER, 14, 0x3FFF);

float target;

float step = 0.2; // angle step

const float span = 3.14/4; // allowed rotation in each direction

float uBound, lBound;

float maxv = 0, maxi = 0; // max voltage and current Q

bool motorEnable = true;

long ts, ts2;

// commander interface

Commander command = Commander(Serial);

void doTarget(char* cmd){ command.motor(&motor, cmd); }

void setup() {

ts = millis();

ts2 = millis();

Serial.begin(115200);

Serial.println("SETUP");

// initialise magnetic sensor hardware

sensor.init();

motor.linkSensor(&sensor);

Serial.println("Sensor Ready");

// DRV8302 specific code

// M_OC - enable over-current protection

pinMode(M_OC,OUTPUT);

digitalWrite(M_OC,HIGH);

// M_PWM - enable 3pwm mode

pinMode(M_PWM,OUTPUT);

digitalWrite(M_PWM,HIGH);

// OD_ADJ - set the maximum over-current limit possible

// Better option would be to use voltage divisor to set exact value

pinMode(OC_ADJ,OUTPUT);

digitalWrite(OC_ADJ,HIGH);

pinMode(OC_GAIN,OUTPUT);

digitalWrite(OC_GAIN,LOW);

Serial.println("Driver config");

_delay(1000);

// configure driver

driver.voltage_power_supply = 36;

driver.voltage_limit = driver.voltage_power_supply;

driver.pwm_frequency = 15000;

driver.init();

Serial.println("Driver init");

_delay(1000);

motor.linkDriver(&driver);

// link current sense and the driver

currentSense.linkDriver(&driver);

currentSense.init();

currentSense.skip_align = true;

// link the current sense to the motor

// driver 8302 has inverted gains on all channels

currentSense.gain_a *=-1;

currentSense.gain_b *=-1;

currentSense.gain_c *=-1;

motor.linkCurrentSense(¤tSense);

// limiting motor movements

motor.voltage_limit = 24; // [V]

motor.velocity_limit = 20;

motor.voltage_sensor_align = 4;

motor.velocity_index_search = 3;

// set control loop type to be used

motor.controller = MotionControlType::angle;

// velocity PI controller parameters

motor.PID_velocity.P = 1.0;

motor.PID_velocity.I = 15.0;

motor.LPF_velocity.Tf = 0.02; // velocity low pass filtering time constant

// jerk control using voltage voltage ramp

// default value is 300 volts per sec ~ 0.3V per millisecond

motor.PID_velocity.output_ramp = 1000;

// position P controller parameters

motor.P_angle.P = 1.0;

motor.P_angle.I = 0.0;

motor.P_angle.D = 0.0;

// use monitoring with serial for motor init

// monitoring port

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

motor.sensor_direction = Direction::CCW;

motor.zero_electric_angle = 1.88;

// initialize motor

motor.init();

motor.initFOC();

delay(100);

target = sensor.getAngle(); // set target

uBound = target + span;

lBound = target - span;

// downsampling

motor.motion_downsample = 10;

motor.monitor_downsample = 10; // default 10

// define the motor id

char motor_id = 'M';

command.add(motor_id, doTarget, "motor");

// configuring the monitoring to be well parsed by the webcontroller

//motor.monitor_start_char = motor_id; // the same latter as the motor id in the commander

//motor.monitor_end_char = motor_id; // the same latter as the motor id in the commander

//command.verbose = VerboseMode::machine_readable; // can be set using the webcontroller - optional

Serial.println("Setup DONE");

_delay(1000);

}

void loop() {

motor.loopFOC();

motor.move(target*(-1));

//motor.monitor();

//command.run();

}