First of all, I would like to express my gratitude to the individuals responsible for creating this fantastic library. I am a university student in Japan, so I apologize in advance for any shortcomings in my English.

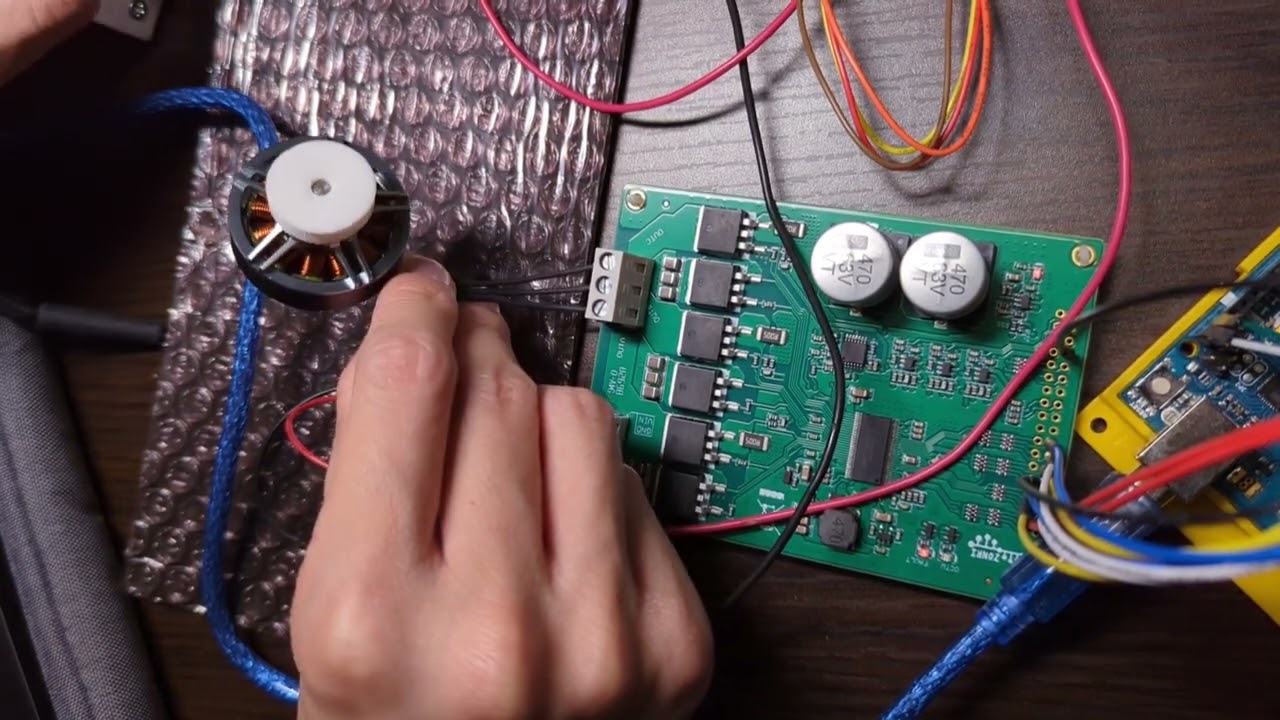

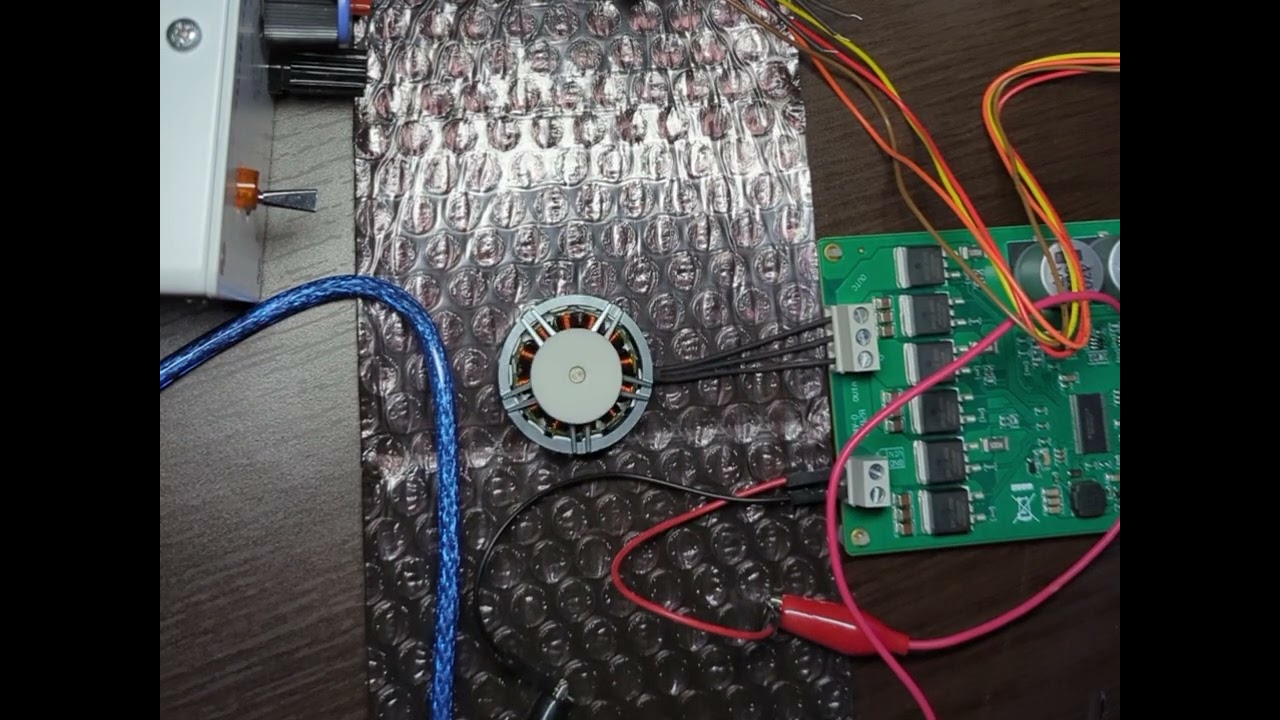

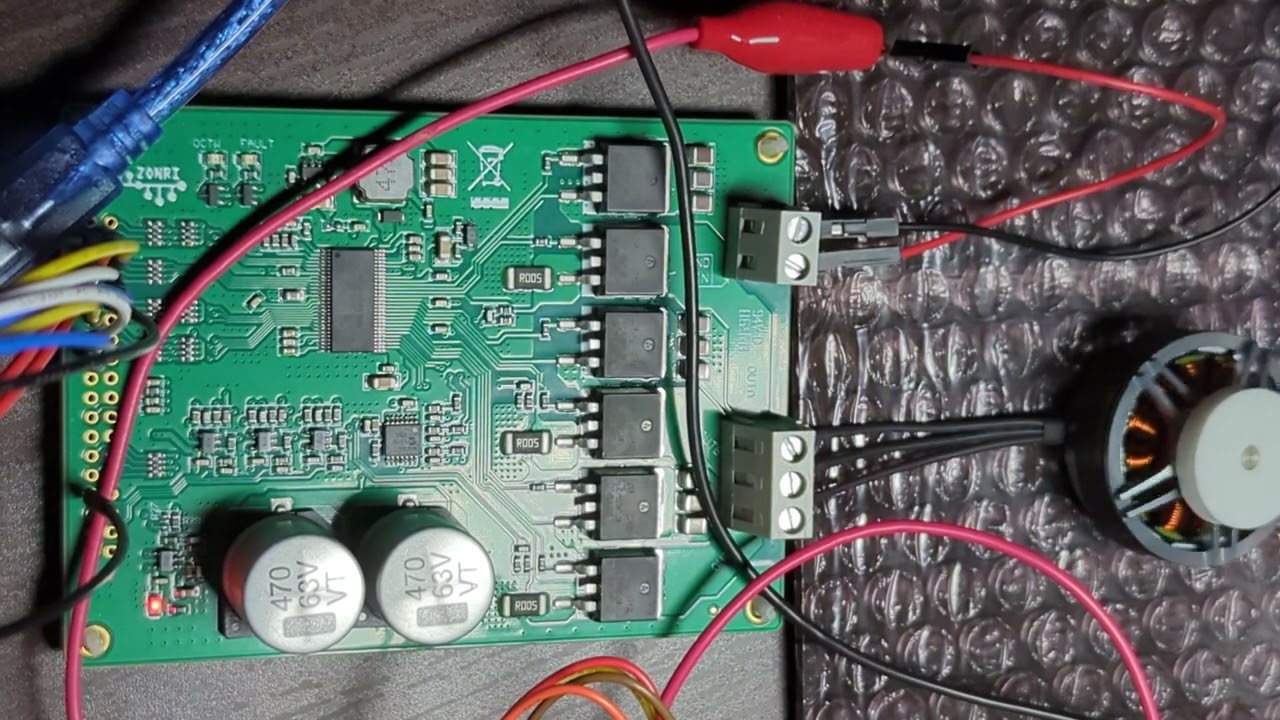

The system I am using consists of an Arduino Uno, a DRV8302 motor driver, an AS5600 magnetic sensor, and a SunnySky V2806 motor. The code I am using is based on a sample code provided in the documentation. The code I have implemented is nearly identical to the sample code.

/* ----- Pin setting -----

PC4 - Analog 4 - Encoder SDA

PC5 - Analog 5 - Encoder SCL

*/

#include <SimpleFOC.h>

// DRV8302 pins connections

// don't forget to connect the common ground pin

#define INH_A 5

#define INH_B 9

#define INH_C 11

#define INL_A 6

#define INL_B 10

#define INL_C 3

#define EN_GATE 8

#define M_PWM 6

#define M_OC 5

#define OC_ADJ 7

// motor instance

BLDCMotor motor = BLDCMotor(11);

// driver instance

BLDCDriver6PWM driver = BLDCDriver6PWM(INH_A, INL_A, INH_B, INL_B, INH_C, INL_C, EN_GATE);

MagneticSensorI2C sensor = MagneticSensorI2C(AS5600_I2C);

// commander interface

Commander command = Commander(Serial);

void onMotor(char *cmd) { command.motor(&motor, cmd); }

void setup()

{

// configure i2C

Wire.setClock(400000);

// initialise magnetic sensor hardware

sensor.init();

// link the motor to the sensor

motor.linkSensor(&sensor);

// DRV8302 specific code

// M_OC - enable over-current protection

pinMode(M_OC, OUTPUT);

digitalWrite(M_OC, LOW);

// M_PWM - enable 6pwm mode (can be left open)

pinMode(M_PWM, OUTPUT);

digitalWrite(M_PWM, LOW);

// OD_ADJ - set the maximum over-current limit possible

// Better option would be to use voltage divisor to set exact value

pinMode(OC_ADJ, OUTPUT);

digitalWrite(OC_ADJ, HIGH);

// configure driver

driver.voltage_power_supply = 12;

driver.init();

motor.linkDriver(&driver);

// choose FOC modulation

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set control loop type to be used

motor.controller = MotionControlType::torque;

// controller configuration based on the control type

motor.PID_velocity.P = 0.2;

motor.PID_velocity.I = 20;

// velocity low pass filtering time constant

motor.LPF_velocity.Tf = 0.01;

// angle loop controller

motor.P_angle.P = 20;

// angle loop velocity limit

motor.velocity_limit = 50;

// default voltage_power_supply

motor.voltage_limit = 12;

// use monitoring with serial for motor init

// monitoring port

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align encoder and start FOC

motor.initFOC();

// set the initial target value

motor.target = 2;

// define the motor id

command.add('M', onMotor, "motor");

_delay(1000);

}

// velocity set point variable

float target_velocity = 5; // 2Rad/s ~ 20rpm

void loop(){

// iterative setting FOC phase voltage

motor.loopFOC();

// iterative function setting the outer loop target

// velocity, position or voltage

// if target not set in parameter uses motor.target variable

motor.move(target_velocity);

// user communication

command.run();

}

Based on the serial monitor output, it appears to be functioning correctly, as shown below. However, in reality, the FAULT LED lights up and the operation comes to a halt, as demonstrated in the video (https://youtu.be/jb0efc9v35U).

MOT: Monitor enabled!

MOT: Init

MOT: Enable driver.

MOT: Align sensor.

MOT: sensor_direction==CCW

MOT: PP check: fail - estimated pp: 78.77

MOT: Zero elec. angle: 0.67

MOT: No current sense.

MOT: Ready.

I also attempted to run the “magnetic_sensor_i2c_example” code, which was mentioned in a previous question, but it didn’t seem to have any noticeable issues. I am unsure why this behavior is occurring.

I would greatly appreciate your assistance in resolving this matter.