Progress - ISH…

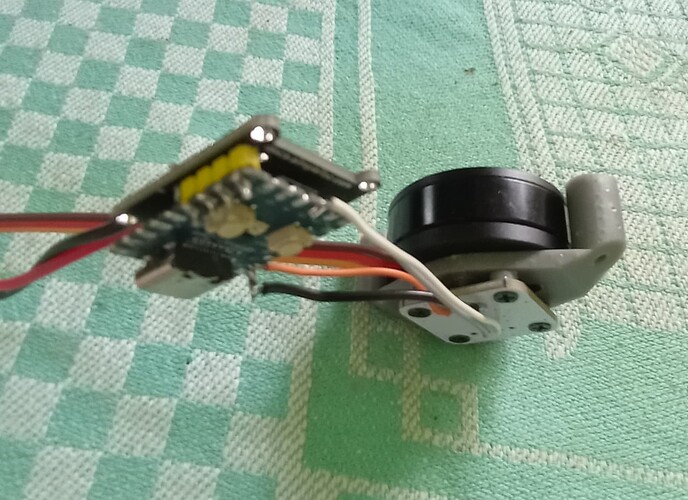

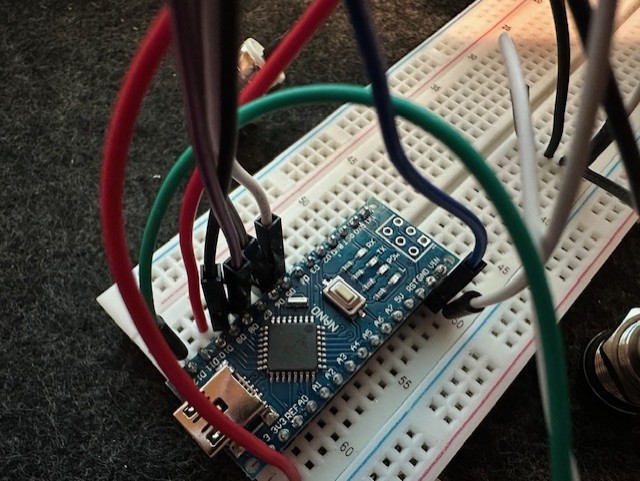

I went back to basics, and found the below code, where I modified the motor.target based on 6.28 being 1 Revolution per second, and adjusted to get close to 33.3RPM and 45RPM.

I’ve left out the button stuff, for now - I just wanted to get the motor moving.

The only issue I have here (until I start adding bits) is the consistency of movement.

it fluctuates around 33.3 and 45, but with slight dips and spikes (more than with the FOC Shield and Uno.

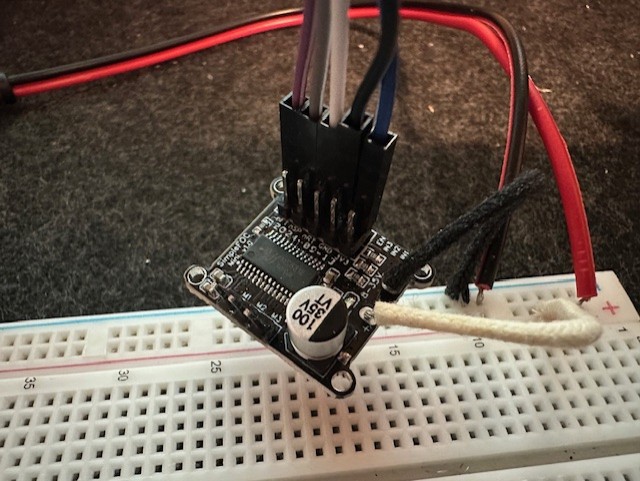

So - My question for right now, is - is this due to the code and fluctuations the voltage as indicated by me, or is that more likely to be from poor voltage / current supplied by my FOC Mini, which I suspect to be a clone (Amazon UK Purchase).

Is this something that the proper FOC mini would solve, or is the issue still in the code (or a combination)?

side Question - The official page says out of stock on the thumbnails for the SimpleFOC boards, but the main page shows an order button. Are they available officially, or is the shop no longer an official channel? I can buy from AliExpress, but if the board i have is the issue, I have no guarantee that the one I get from somewhere else would be made using bettr components.

#include <SimpleFOC.h>

// BLDCMotor(pole pair number, phase resistance (optional) );

BLDCMotor motor = BLDCMotor(11);

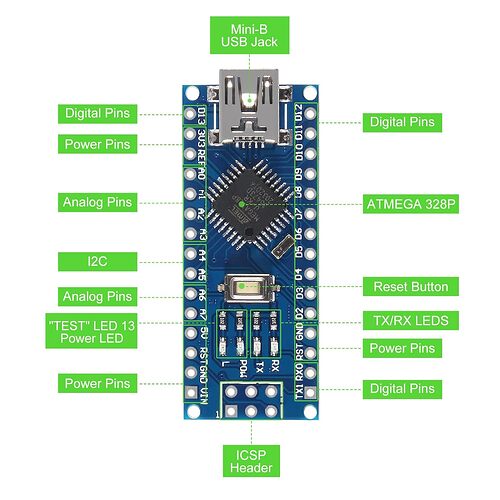

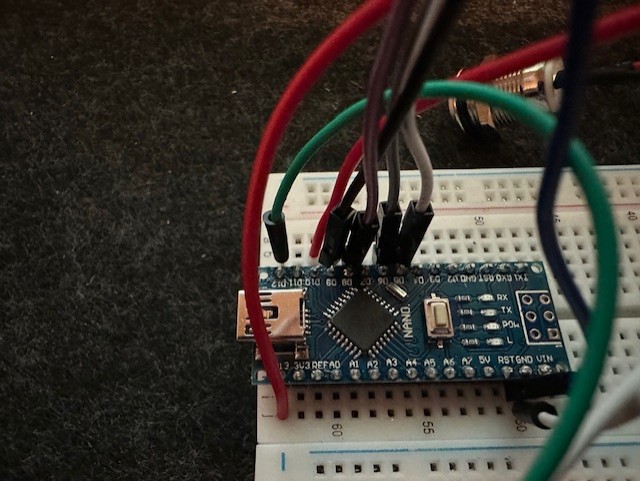

// BLDCDriver3PWM(pwmA, pwmB, pwmC, Enable(optional));

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&motor.target, cmd); }

void doLimit(char* cmd) { command.scalar(&motor.voltage_limit, cmd); }

void setup() {

// use monitoring with serial

Serial.begin(115200);

// enable more verbose output for debugging

// comment out if not needed

SimpleFOCDebug::enable(&Serial);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

// limit the maximal dc voltage the driver can set

// as a protection measure for the low-resistance motors

// this value is fixed on startup

driver.voltage_limit = 6;

if(!driver.init()){

Serial.println("Driver init failed!");

return;

}

// link the motor and the driver

motor.linkDriver(&driver);

// limiting motor movements

// limit the voltage to be set to the motor

// start very low for high resistance motors

// current = voltage / resistance, so try to be well under 1Amp

motor.voltage_limit = 12; // [V]

// open loop control config

motor.controller = MotionControlType::velocity_openloop;

// init motor hardware

if(!motor.init()){

Serial.println("Motor init failed!");

return;

}

// set the target velocity [rad/s]

//motor.target = 3.48; // 33.3RPM

motor.target = 4.71; // 45RPM

// add target command T

command.add('T', doTarget, "target velocity");

command.add('L', doLimit, "voltage limit");

Serial.println("Motor ready!");

Serial.println("Set target velocity [rad/s]");

_delay(1000);

}

void loop() {

// open loop velocity movement

motor.move();

// user communication

command.run();

}