Based on the experimentation I have undertaken, I think I will need anti-cogging functionality. I am trying to make a quiet fan, but the number two source of noise is the cogging of the motor. I have been able to determine this reliably by noting the noise level while the motor is coasting (thus, no noise caused by chopping of the electronics, which is the primary noise source, actual air turbulence/noise is number three).

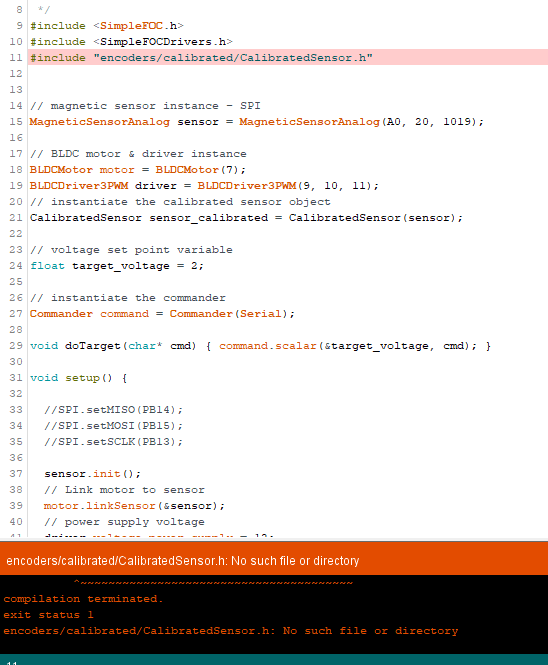

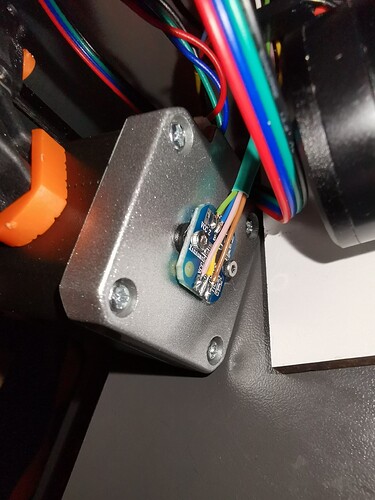

I ordered a simplefoc board and angle sensor but it hasn’t arrived yet. I’m anticipating that using an angle sensor will naturally provide some anti-cogging tendency, as the system tries to produce smooth motion. However the PID control loop that is meant to provide the smooth motion will likely not be able to dampen the effects of cogging very well, due to response time limitations. It needs more predictive ability than a pid control loop can provide.

There are many papers on e.g. google scholar, which discuss algorithms and approaches for motor drivers to implement anti-cogging, and I think it fits in well with the high level goals of the simpleFOC project. I don’t have much money to spend on this as my project is supposed to be a side hustle and is proving to have doubtful return on investment promise as it is, however I think I can muster the $ to pay for prototype boards, do the work of testing on a common gimbal motor and do research on the algorithms, I know a little C and may be able to do the work myself, but my coding skills are limited so I could definitely use any help I can get.

Is anyone interested in collaborating? BTW my project is www.openerv.org.

I have investigated other drivers, but simplefoc appears to be my only hope for anti-cogging. Also it’s conceivable that the current control strategy, which is noise source number 2, could be a problem with other drivers, and with SimpleFOC there is at least hope that if it’s an issue, I can change it by increasing the frequency above the audible frequency range or whatever.

The commercially available driver ICs don’t seem to have any provisions for cogging, and although they are supposed to be made for producing quiet fans, I’m not convinced they did a decent job of it, because I have noticed that a lot of quiet fans on the market actually make a lot of motor noise due to the drive electronics. People generally don’t understand the value or point of making things quiet, so it is really an uphill battle, you can’t get suitable components at many levels. Also I would like to use general purpose widely available components and open source whenever possible.