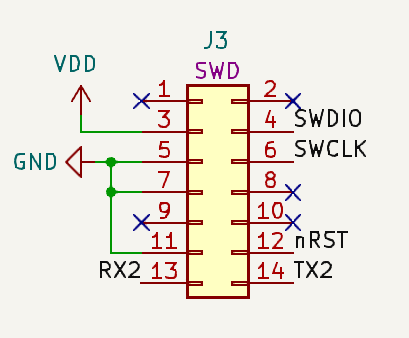

I have the V3 minie- it’s great. It has a b2b with the same footprint as the connector I used- but I don’t recommend it because of the low mating cycles. I always use the 2x7 STDC14 connector, but my (hope) for this project is that whichever device is connected to the PC directly via USB can be re-flashed with DFU mode, so that end-user doesn’t need to mess with flashing hardware or anything. This is why I needed to be able to enter DFU from in-software, so that the button does one thing when connected to a serial port and different behavior when it’s farther down the chain (going to use for CAN node discovery)

re: magnetism through PCB, I have not had issues, but I could really imagine this would be an issue for anyone doing higher speed things. I made sure the plane(s) underneath the chip are solid so no interference. All the high current traces are away from the MT6701. To be honest, I think having the magnet in front of the PCB is easier- you can have a larger distance. With this design from the back, you basically have to have the magnet as close as possible to the PCB, so you are limited in vertical space for any wiring.

The main project I am developing this for is an array of peristaltic pumps (pumps that move fluid without touching it via some lobes engaging with tubing). So if you had a few pumps with different chemicals, you can set up however many motors you need for the experiment, then they are individually addressable via a single USB connection at the end. For standard CAN this means you could have up to 64 nodes but in general I expect this to be used from an array of 3-5. Closed loop means precise dispensing and FOC means that they are very efficient. It’s not designed for the whole thing to be powered over USB, but for a single node it’s totally possible and could have it’s own use. There are two pads meant for straddle-mounting some 1x2 connector on the edge of the PCB for a power supply braid to run along one edge and drop off the required power at each node for situations where USB 500mA is not enough.

This is also a development board for some haptic texture type things. I really enjoy the ScottBez smartknob project and have been having fun with exploring force-feedback knobs.