Hi All!

I have designed a custom sensor PCB that can be mounted inside Hoverboard motors. Some of you might have read about this on the Discord already.

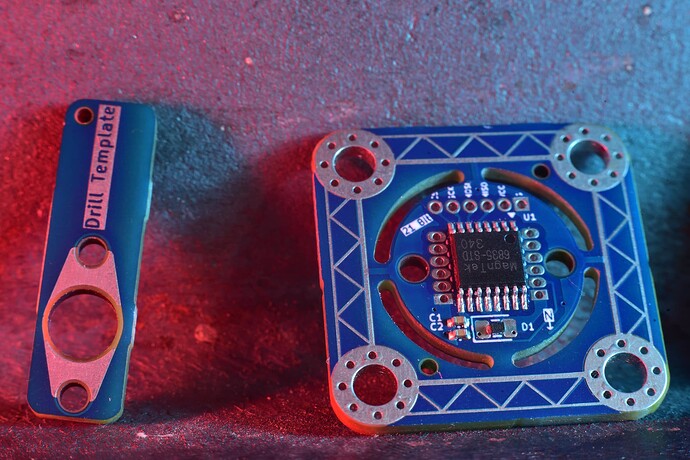

I took inspiration from attemps like here, but wanted to make this a bit more permanent and easier to reproduce by different people. The sensor board I designed uses the 21 Bit MT6835 and breaks out all the pins. You can mount this either on hoverboard motors by removing the disk shaped part, or use the 25*25mm M3 holes to screw it directly to matching motors.

The reason I designed these is that I want to try building a direct-drive telescope mount with hoverboard motors. The angular resolution of the MT6835 is about half an arcsecond, which is on the same order as many telescopes. I don´t expect to get stellar performance (no pun intended…), but instead just want to see how good I can get the tracking.

This idea of using Hoverboard motors is not my own, instead Astroboden built a direct-drive, but open-loop mount and used star guiding successfully.

I have modified one motor already, and am working on a second one. From first tests it looks like the sensor is completely noiseless, at least at zero to slow speeds. I can get following errors of about 5 arcseconds with just some basic PID tuning.

Anyways, I have put all the files and a guide for modifying Hoverboard motors on GitHub here.

I will post some updates here if I make significant progress with the project.