@slomobile

That’s extremely challenging. I will watch this and hopefully learn.

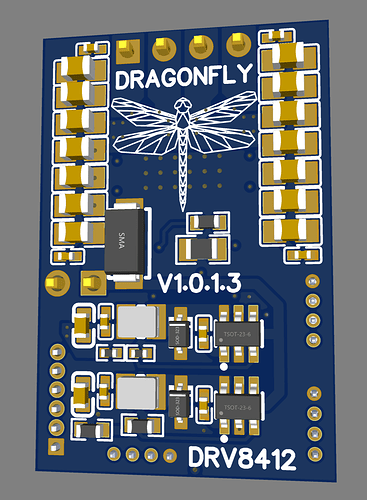

I designed a generic board like that, but it came out really expensive. This is the board:

If you are interested, I could open the design. Check out this thread.

Question, do you have anything to do with SLO Cal Poly? Or slomobile is just something else?

Cheers,

Valentine

1 Like