@Antun_Skuric

Thanks for your help!

I found that the problem was that my PI control parameters were too high,

Now PI is like this, I successed to make the motor turn

motor.PI_ velocity.P = 0.1;

motor.PI_ velocity.I = 5;

pole pair number is 14

The encoder uses as5047u and is connected through SPI

The current library version is 1.3.0

But the starting current of the motor is 18A (after MOT: Enable.), so I limit the current on DC power to less than 5A, which will cause noise during starting.!!

I’m using the motor of the aircraft with an internal resistance of 0.2 ohm.

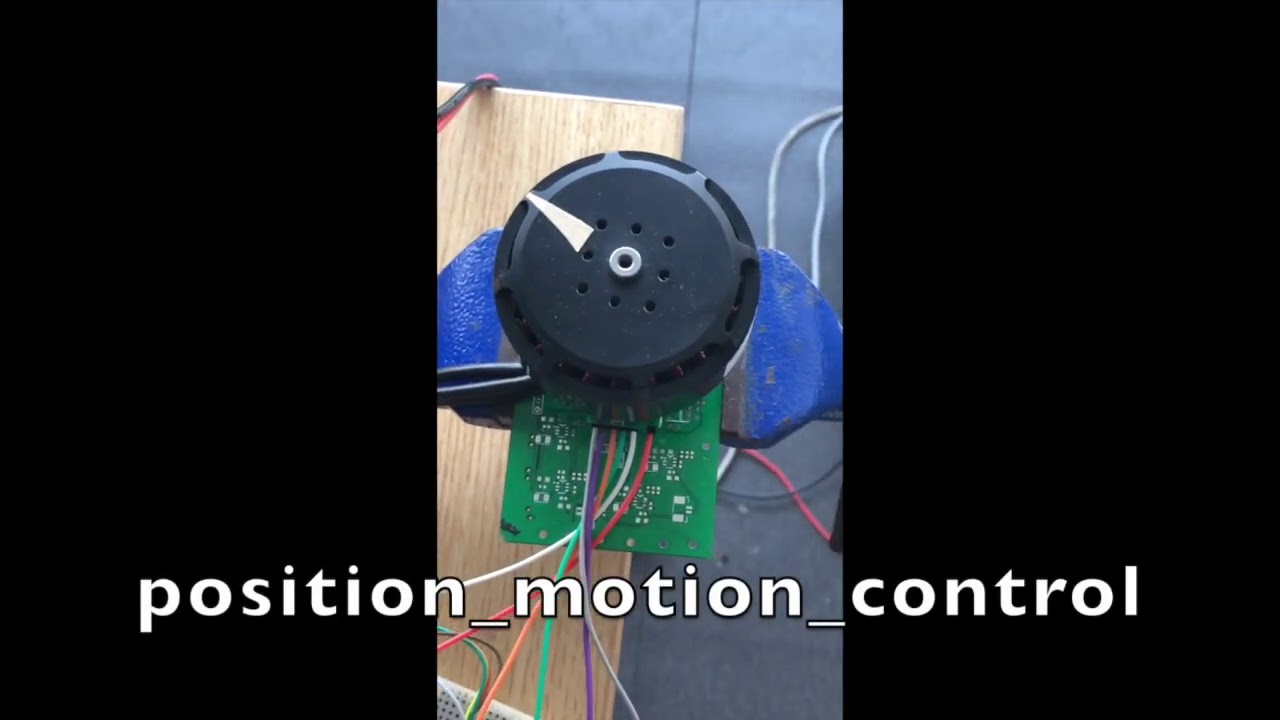

(Please watch this video for details,The “Target voltage” and “Target angle” are adjusted through the serial port in the video screen)

(There will be a clicking noise when the motor is highspeed)

- List item